An intelligent support sliding bearing device with adjustable clearance and a clearance adjustment method

A technology of sliding bearings and gaps, which is applied in the field of intelligent supporting sliding bearing devices, can solve problems such as gaps in screw transmission, slow action response, and screw damage, and achieve the effect of improving response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

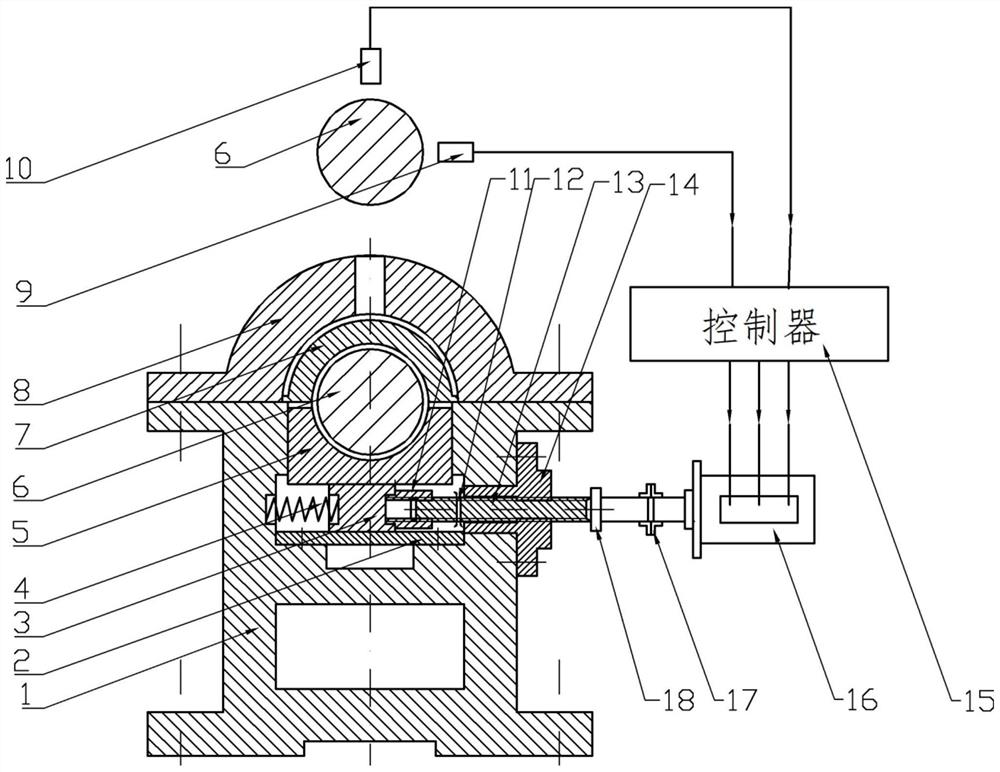

[0024] The present invention will be further described below with reference to the accompanying drawings.

[0025] like figure 1 As shown, a gap-adjustable intelligent support sliding bearing device includes a support sliding bearing, a vertical displacement sensor 10, a horizontal displacement sensor 9, and a controller 15, and the support slide bearing is provided, and the slurry block 3 is provided below. The guide rail 2, the bottom surface of the oblique block 3 is slidably fitted, and the oblique block 3 moves axially along the guide rail 2, the top surface of the slope 3 is 1: 125 taper, slide on the guide rail, and the shaft watt can withstand heavy The load, and reliably operate, which can greatly reduce the implantive force required for the oblique block movement; one end of the oblique block 3 is provided, and the other end of the oblique block 3 is connected to the reset spring 4, the slope 3 is disposed in the support seat 1 The reset spring 4 is disposed between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com