Glass lens hot-pressing device

A technology of hot pressing device and glass lens, which is applied in the direction of glass pressing, glass forming, glass manufacturing equipment, etc., which can solve the problems of increased process, low efficiency, and easy sticking, so as to improve the degree of mechanization, reduce manual processes, The effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

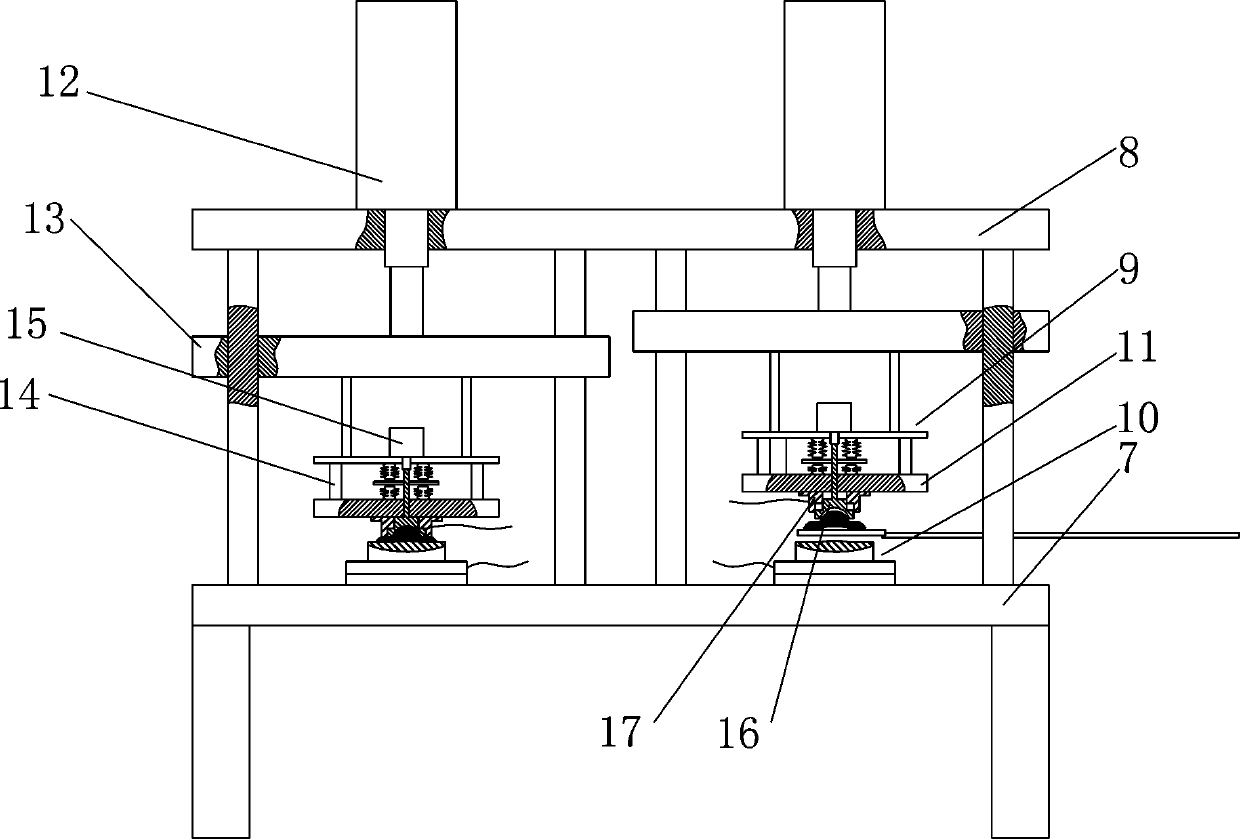

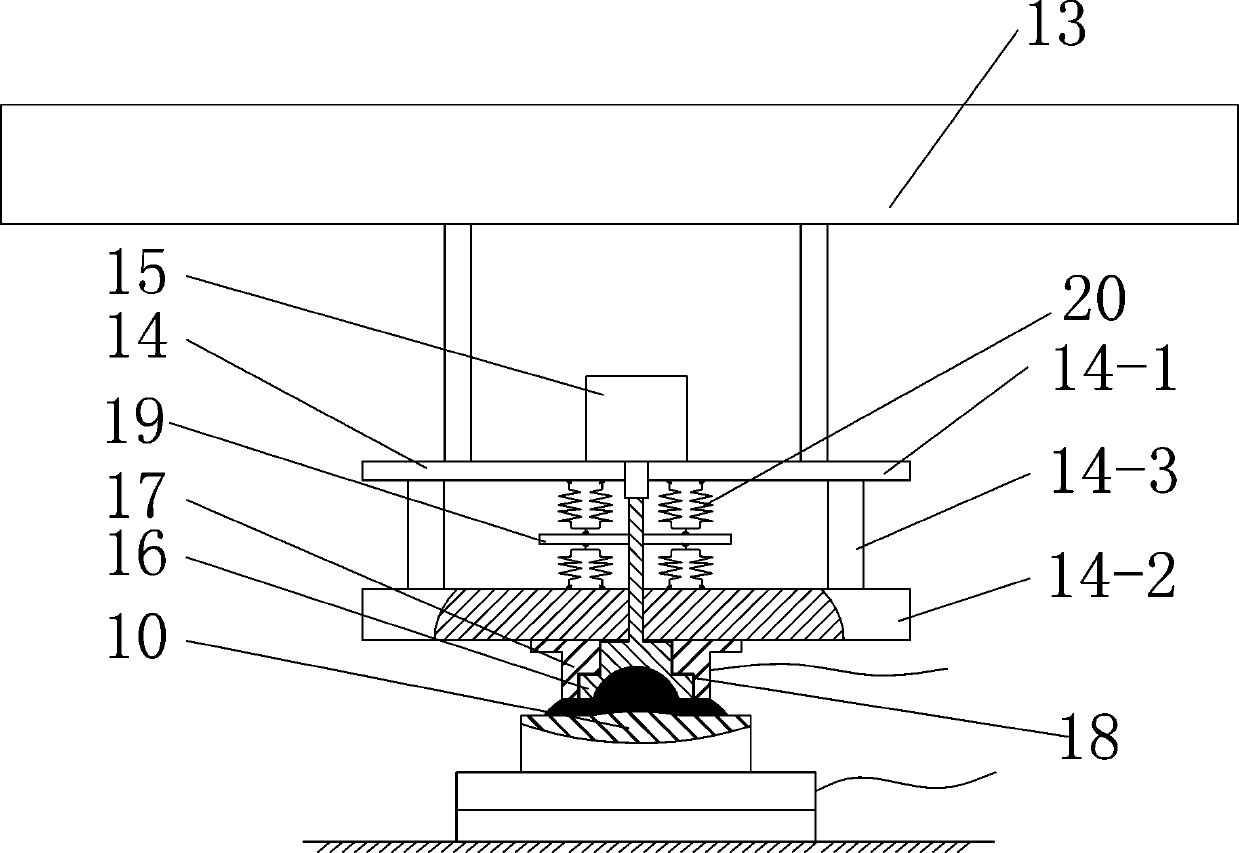

[0020] Such as Figure 2-4 As shown, a glass lens hot-pressing device includes a hot-pressing workbench 7. Eight guide rods are arranged on the hot-pressing workbench 7. The eight guide rods are distributed in two rows of arrays. The upper ends of the eight guide rods are fixed and installed organically. seat 8. A first air cylinder 12 is respectively arranged on the left and right sides of the support 8, and the first air cylinder 12 also can adopt a hydraulic cylinder. The lower end of the piston rod of each first cylinder 12 is fixedly connected with a sliding plate 13, the sliding plate 13 is provided with four through holes in the circumferential direction, the sliding plate 13 passes through the guide rod through the through holes, and can move up and down along the guide rod . When the piston rod of the first cylinder 12 stretches in and out like this, the sliding plate 13 can move up and down.

[0021] The sliding plate 13 is fixedly connected to the installation fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com