Multifunctional automatic wrench

An automatic wrench and multi-functional technology, applied in the direction of wrenches, screwdrivers, manufacturing tools, etc., can solve the problems of limited operating space, slow work of adjusting the width of the opening, and low work efficiency, so as to quickly tighten or disassemble nuts and change the driving mode , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

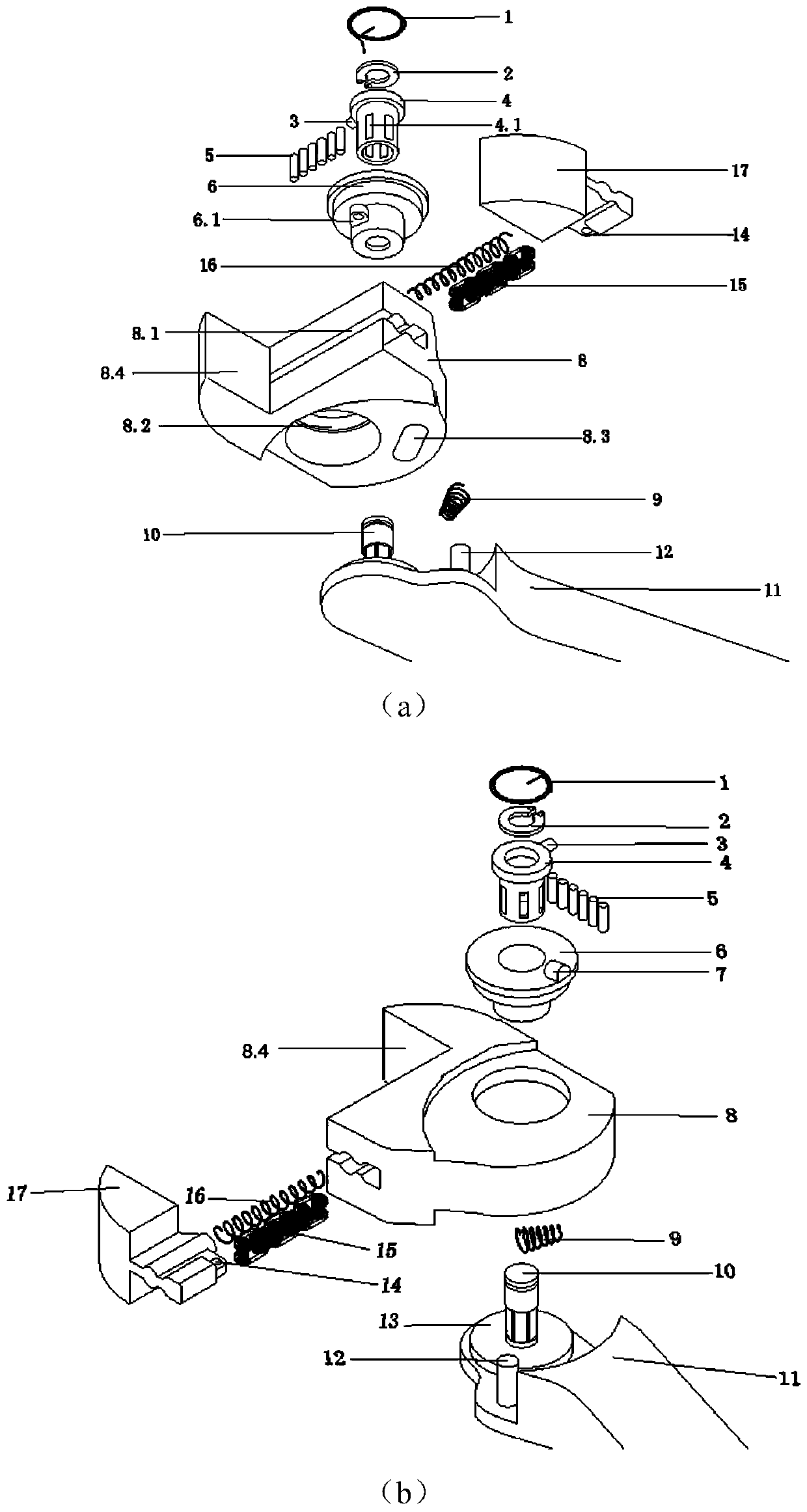

Embodiment 1

[0031] This embodiment provides a multifunctional automatic wrench, the wrench mainly includes four parts: a wrench head 8, a lower tooth lip, a handle 11 and a quick drive mechanism; the wrench head 8 is an integral forging, including a wrench head Slideway 8.1, wrench head spindle accommodation groove 8.2, stopper accommodation groove 8.3 and fixed tooth lip 8.4; the lower tooth lip includes lower tooth lip slider 17 and lower tooth lip slider chain connection 14 ; The lower lip slider 17 is in a sawtooth shape, which can replace the pipe wrench to firmly lock and bite the round object; the handle 11 is an integral forging, and the front end of the handle 11 is provided with a main shaft 10, a stopper 12 and a positioning Block 13; the main shaft 10 is located at the center of the positioning block 13 and connected with it; the fast drive mechanism mainly includes a torsion spring 1, a retaining spring 2, an inner ring switch 3, an overrunning clutch, a roller 5, and an outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com