Thermistor

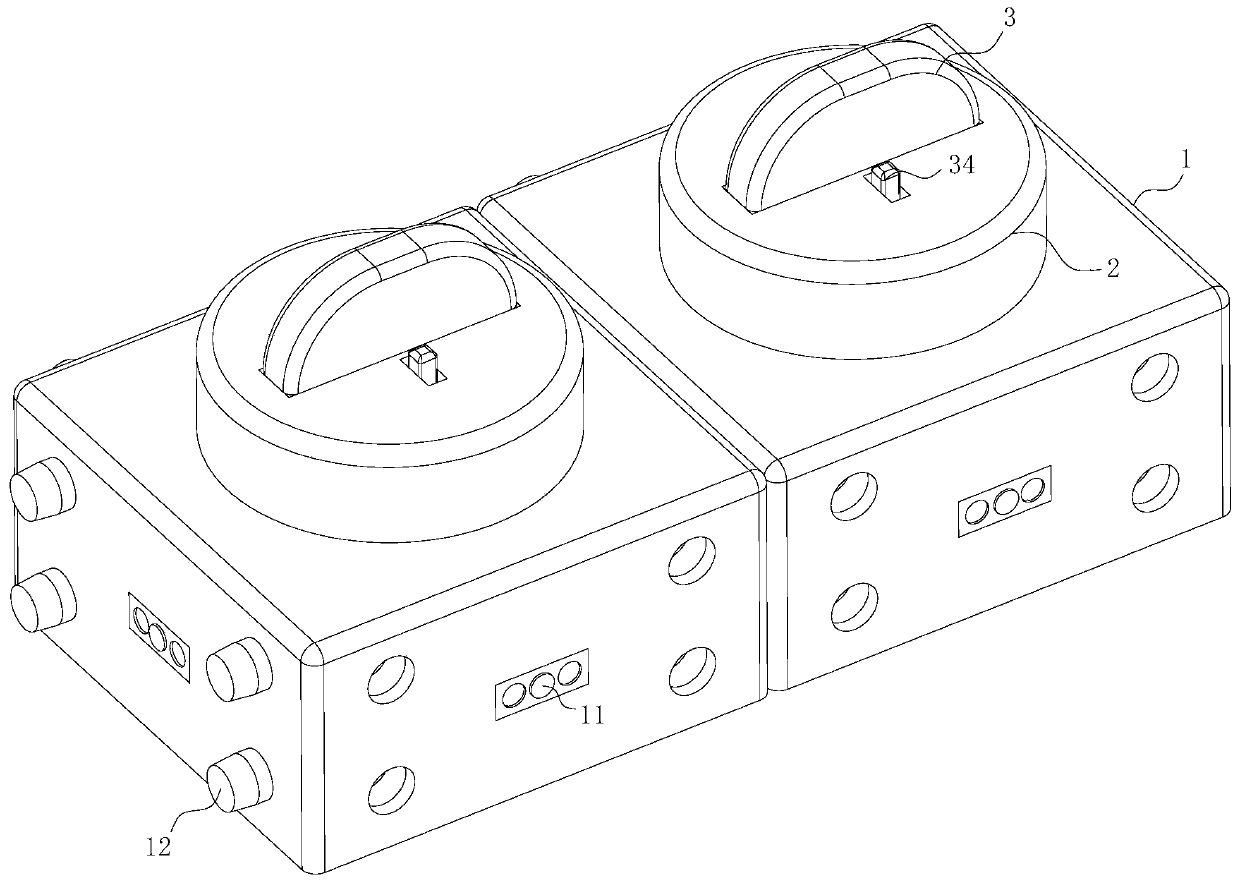

A technology of thermistor and conductive block, which is applied in the direction of resistance terminal/electrode, resistor installation/support, resistor with positive temperature coefficient, etc. It can solve the problem of small resistance of thermistor, cumbersome wiring, and difficulty in meeting circuit protection requirements. role and other issues, to achieve the effect of increasing compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

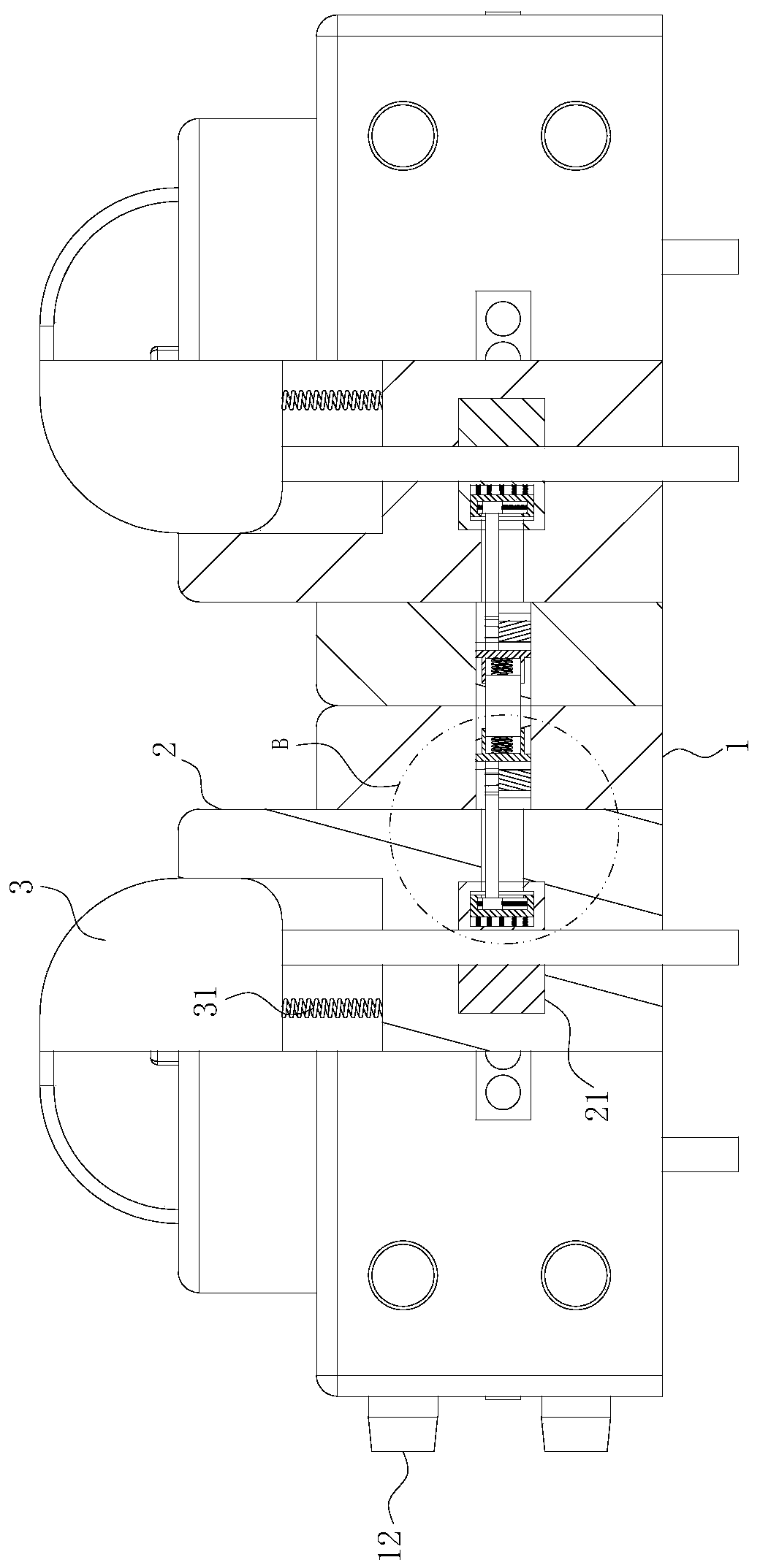

[0024] As an embodiment of the present invention, the mounting seat 1 is fixedly connected with a conductive piece 13 between the conductive joint 11 and the conductive rod 22; guide ring 14, and the conductive joints 11 are all slidably connected in the corresponding guide rings 14; the first spring 15 is firmly connected between the conductive joints 11 and the corresponding conductive sheets 13; the mounting base 1 is connected to the conductive joints 11 Suction grooves are provided on both sides of the suction groove; magnets are slidably connected to the inside of the suction groove; connecting rods are firmly connected between the two magnets and the corresponding conductive joints 11; during work, due to the two mounting seats 1 are only connected through the post 12 and the socket, it is difficult to control whether the post 12 is fully inserted into the socket, and during the installation process or use, the two mounting bases 1 will be loose due to shaking, which wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com