Method for realizing liquid refractive index measurement by utilizing Newton ring

A liquid refractive index and Newton ring technology, which is applied in the direction of phase influence characteristic measurement, etc., can solve the problems that the interference order k cannot be too large, troublesome, inconvenient to control, etc., and achieve the effect of simplifying the layout accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

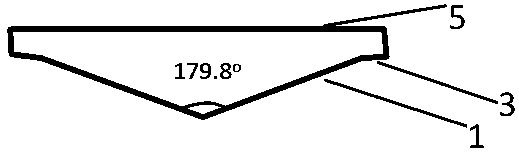

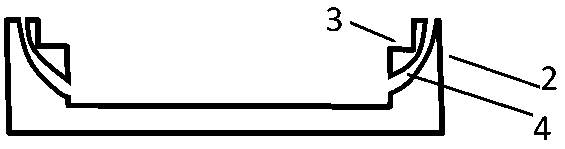

[0009] The existing schematic diagram of the tip is as follows: Figure 7 , the diameter d of filament 13 is the metal wire of about 0.1mm; The shape and size of top glass plate 11 and bottom glass plate 12 can be exactly the same, the length L of top glass plate 11 is generally at 5-6cm, and the length L of top glass plate 11 Thickness is not an important parameter, the thickness design mainly lies in its strength, roughly 1-4mm; the upper surface of the lower glass plate 12 can be electroplated with a reflective film to improve the reflection ability, and the two ends of the simple wedge are bound and adhered by plastic tape to achieve fixation . There is air between the lower surface of the upper glass plate 11 and the upper surface of the lower glass plate 12 .

[0010] In the laboratory, the sodium light lamp is generally irradiated onto the chopping tip perpendicular to the upper surface of the transparent upper glass plate 11 (due to the relatively small diameter d of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com