An on-site multi-directional force detection device for the connection system of the prefabricated building envelope

A technology of building envelope and connection system, which is applied in the field of multi-directional force detection devices on site, can solve the problems of single force direction and cannot simulate the force of connection system, etc., and achieves improved safety, flexible and simple application, and application scope wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

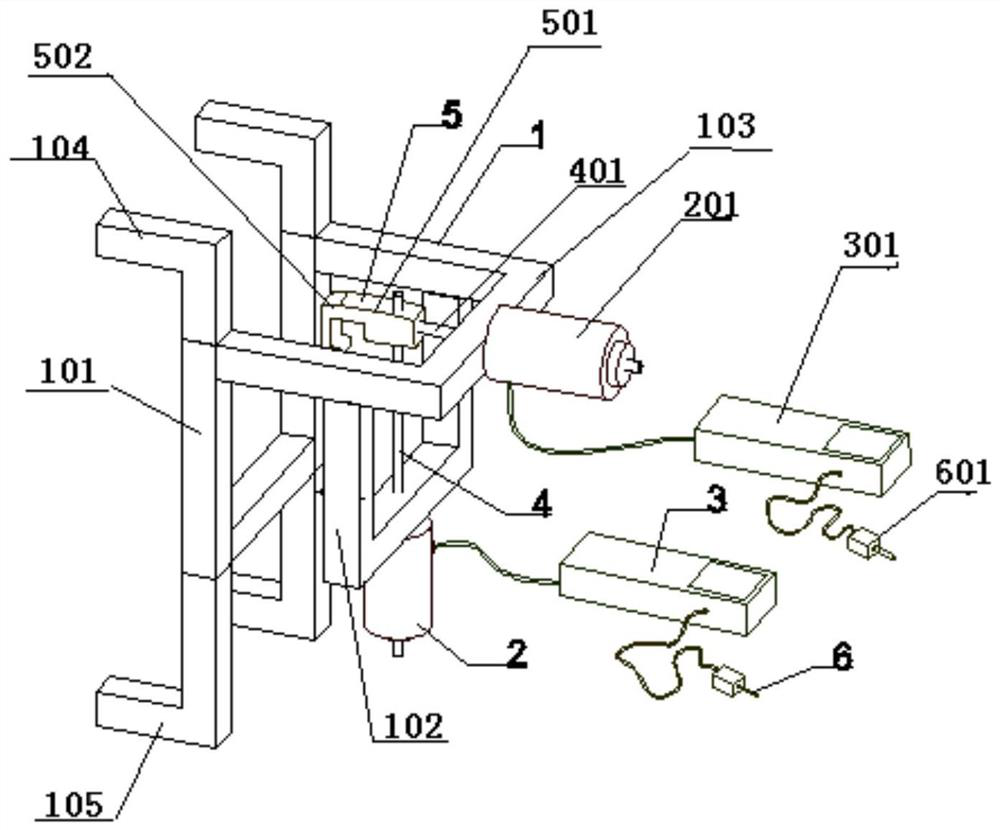

[0031] The structure of the on-site multi-directional force detection device of this embodiment is as follows: figure 1 As shown, the detection device includes an auxiliary supporting tool 1, two loading devices, two controllers, a specimen fixing device 5 and two displacement measuring devices.

[0032] The auxiliary support tooling 1 includes three frames, the frames are rectangular, made of steel, and have the strength to meet the testing requirements. Both the first frame 101 and the second frame 102 are perpendicular to the horizontal ground, the third frame 103 is parallel to the horizontal ground, and the third frame 103 is arranged above the second frame 102 . The second frame 102 is used to support the first loading device 2, and the third frame 103 is used to support the second loading device 201, so that the two loading devices can apply forces in both vertical and horizontal directions to the test piece simultaneously or step by step, At the same time, the first f...

Embodiment 2

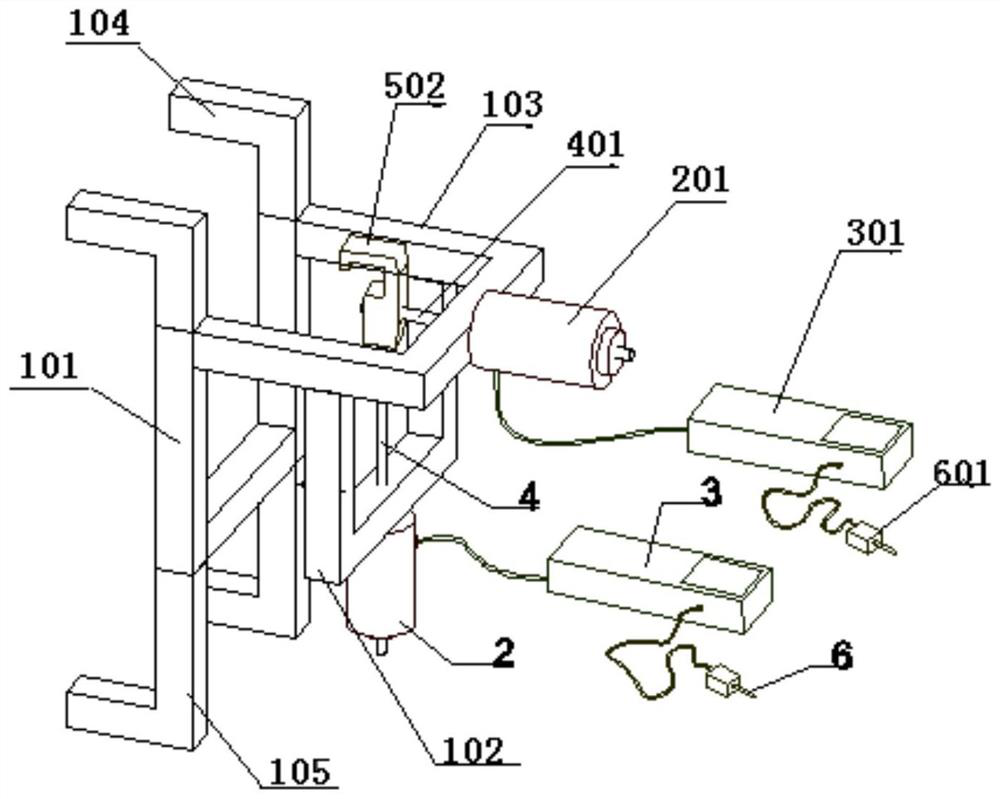

[0043] The structure of the on-site multi-directional force detection device of this embodiment is as follows: figure 2 As shown, the main building structure of this embodiment is placed horizontally and the test piece is located on the side of the main building structure, the first frame 101 and the second frame 102 are respectively stuck on the upper and lower sides of the main building structure, and the third frame 103 is mounted on the building main structure. side of the main structure. The test piece fixing device 5 is placed vertically, the pendant 502 is upward, and the fixed bracket 501 is downward. The pendant 502 can be connected to the test piece on the side of the building main structure, and the second loading device 201 on the third frame 103 applies a vertical load. The first loading device 2 on the second frame 102 applies a load in the horizontal direction. The lower part of the fixing frame 104 is completely retracted into the first frame 101 .

[0044] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com