Hidden connection type wallboard, wall composed of hidden connection type wallboard, decoration structure and installation method

A connection type, wall panel technology, applied in building components, building structures, floors, etc., can solve the problems of time-consuming, affecting the installation effect and aesthetics, adverse installation efficiency, etc., to reduce the labor intensity of workers and improve positioning. Installation efficiency and the effect of improving the stability of the setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

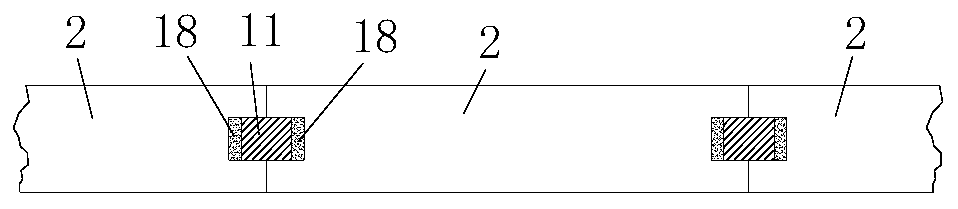

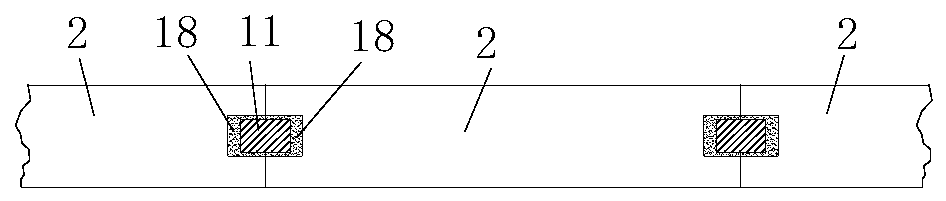

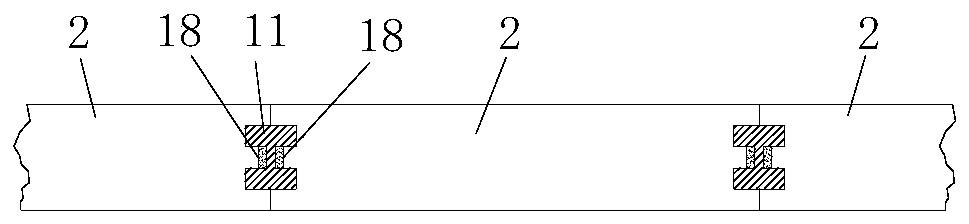

[0062] This embodiment describes a hidden connection type wall panel, including at least two wall panel bodies 2 and a middle frame 11 arranged side by side; the middle frame 11 is buried or half buried between the connecting surfaces of adjacent wall panel bodies 2 to realize Adjacent wallboard bodies 2 are connected. Such as Figure 1(a) to Figure 1(n) As shown, there are many ways to implement the concealed connection wallboard in this embodiment. It only needs to embed the middle skeleton between the connecting surfaces of the adjacent wallboard bodies 2, and the adjacent wallboard bodies can be positioned with each other through the concave-convex structure. The number of wall panel bodies is two, three, four, five, six, or even more, which can be designed according to the construction area.

[0063] Compared with the traditional method of buckling the wallboard body 2 in front of the middle frame 11, the present invention removes the restriction that the distance between...

Embodiment 2

[0066] This embodiment describes a hidden connection wall panel, Figure 2(a) to Figure 2(d) There are four implementations of the wallboard body and the middle frame. The difference from the first embodiment is that in this embodiment, the back side of the middle frame 11 is connected with an adjustment rod 13 that can adjust the extension length. After the wallboard is installed, the front of the wallboard faces the user; if there is a collision with the wallboard, the collision force is applied to the front of the wallboard and faces the rear solid fixture; therefore, the adjusting rod 13 can be adjusted to offset the solid fixture, Entity fixtures provide support to the centering frame 11 through the adjusting rod 13, which can effectively support and position the wallboard, and avoid the wallboard from being hit by the impact due to lack of reasonable support and situations such as sag and collapse.

[0067] The preferred solution is that the middle skeleton is provided w...

Embodiment 3

[0070] This embodiment describes a wall, such as image 3 As shown, including the above-mentioned hidden connection wall panels; in the hidden connection type wall panels, the head end wall panel body 2 and the tail end wall panel body 2 are respectively fixed by the corner frame and the solid fixture; the upper end of the hidden connection type wall panels and The lower ends are directly fixed to the solid fixtures respectively, or are fixed to the solid fixtures through the installation groove structure.

[0071] Fixing with the solid fixture through the installation groove structure means: it also includes the upper and lower bases connected with the solid fixture; the upper and lower bases are respectively provided with installation grooves, and the upper and lower ends of the hidden connection wall panels are respectively plugged in In the installation groove; or the upper end and the lower end of the hidden connection type wall panel are respectively provided with instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com