Curing device for processing carbon fiber products

A curing device and carbon fiber technology, applied in the field of carbon fiber processing equipment, can solve problems such as uneven pressure, inability to treat and discharge cooling water, and easy occurrence of danger, and achieve the effect of easy operation, ensuring the effect of discharge treatment, and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

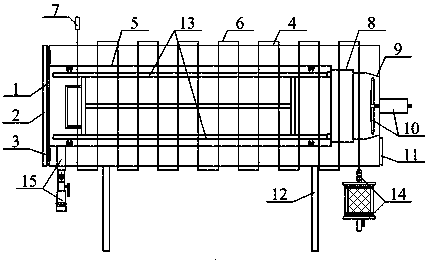

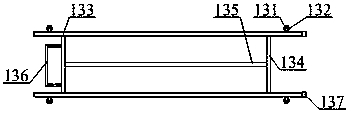

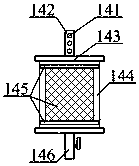

[0033] The present invention is described in detail below in conjunction with accompanying drawing:

[0034]As shown in accompanying drawing 1 and accompanying drawing 2, a kind of curing device for the processing of carbon fiber products according to the present invention includes a sealing ring 1, a tank cover 2, a hinge 3, a curing tank 4, and an iron curing liner 5 , cooling pipe 6, coolant pipe joint 7, heater 8, wind guide cover 9, fan 10, control panel 11, support seat 12, carbon fiber product solidification processing pick-and-place removal frame structure 13, waste water discharge anti-pollution treatment cylinder structure 14 and a curable exhaust protection pressure relief pipe structure 15, the sealing ring 1 is glued around the inner wall of the tank cover 2; the tank cover 2 is installed on the left end of the curing tank 4 through the hinge 3; the described The tank cover 2 is sealed and fastened by the sealing ring 1 and the entrance of the left end of the curi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com