Suspension insulator rotary pin plugging and unplugging device

A suspension insulator and insulator technology, applied in switchgear, overhead line/cable equipment, electrical components, etc., can solve the problems of long working hours, unbalanced stress of insulators, and increase the danger of high-altitude workers, and achieve simple operation, High degree of automation and the effect of reducing the risk of manual work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

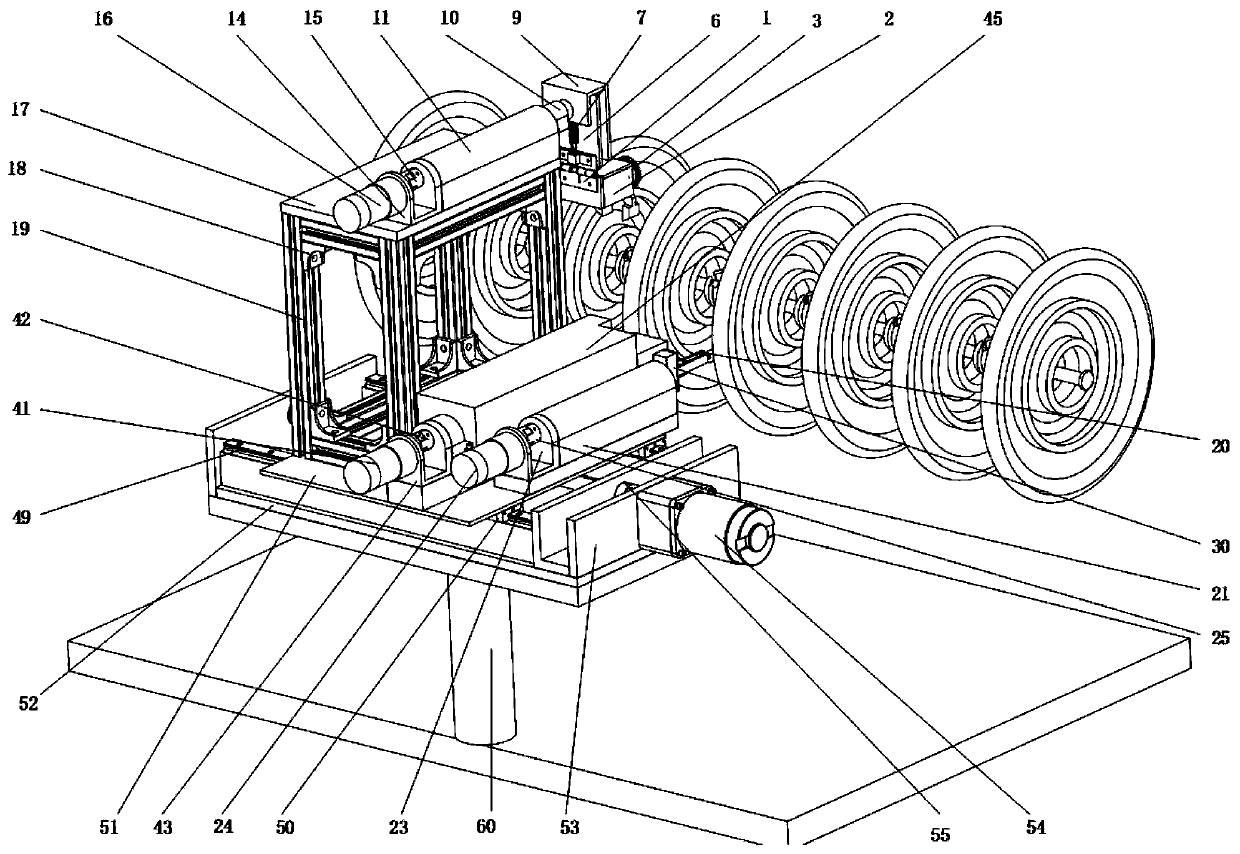

[0030] Such as figure 1 as shown, figure 1It is a structural diagram of the suspended insulator rotary plugging device; the suspended insulator rotary plugging device in the present invention includes an insulator straightening device, an insulator pin pulling device, an insulator plugging device, a lateral moving device and a total fixed base 60 . The lateral moving device is fixedly arranged on the general fixed base 60, and the insulator straightening device, insulator pin pulling device and insulator plugging device are all fixedly arranged on the surface of the lateral transfer flange 51 of the lateral moving device.

[0031] Specifically, the insulator straightening device clamps the insulator sheet through the gear jaw 3, and drives the gear jaw 3 to extend or retract through the servo motor. The gear jaw 3 and the clamping fixed plate 9 The spring hinge 1 and the clamping linear guide rail 8 are used to connect between them, so as to meet the freedom and attitude req...

Embodiment 2

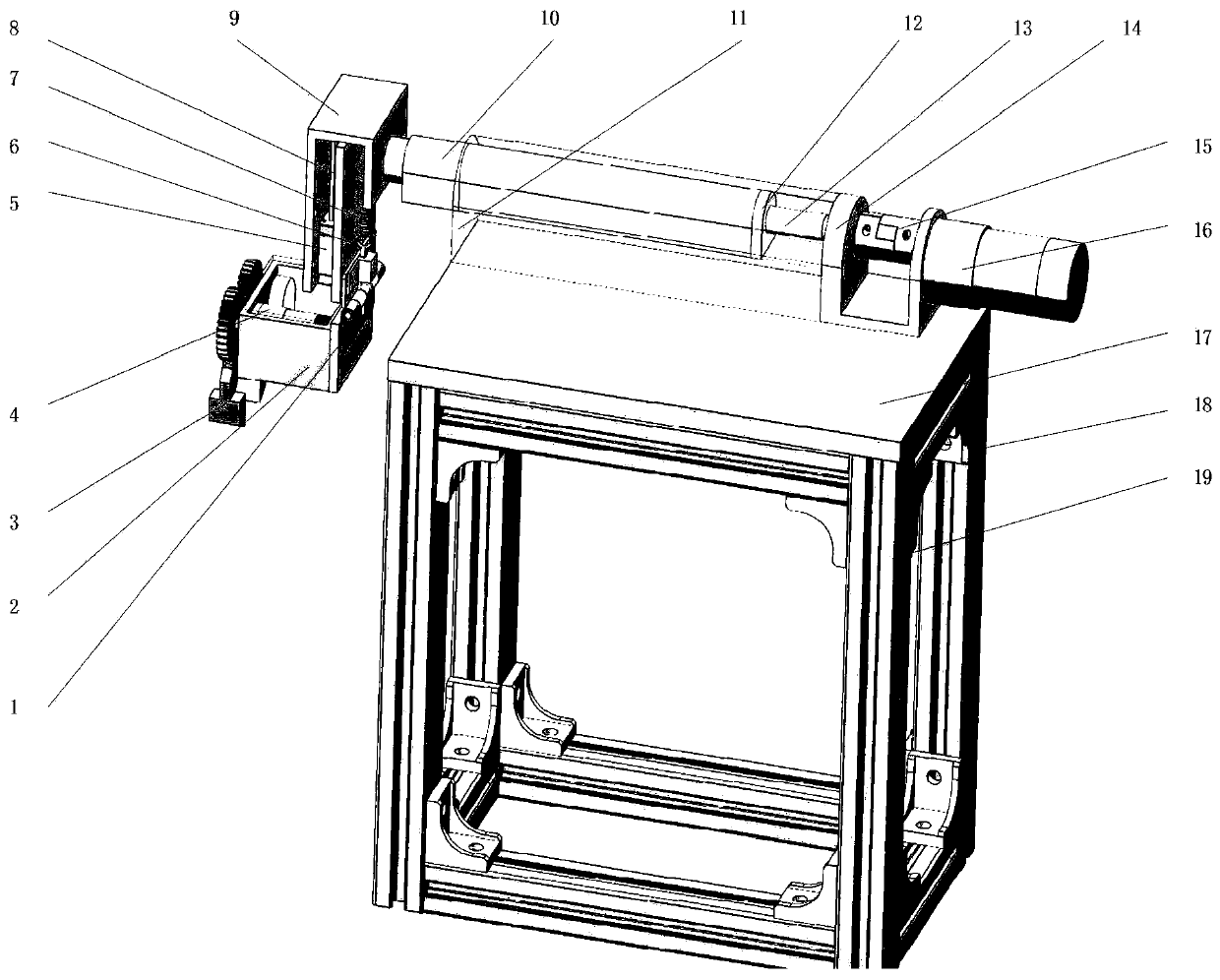

[0035] Such as figure 2 as shown, figure 2 It is a structural schematic diagram of the insulator straightening device; the insulator straightening device includes a profile frame, a straightening telescopic component and a straightening clamping component. The straightening clamping assembly is used to clamp the insulator sheet; the straightening telescopic assembly is used to drive the straightening clamping assembly to clamp the insulator sheet to rotate.

[0036] The straightening telescopic assembly includes a straightening fixed base plate 17, a clamping fixed plate 9, a straightening U-shaped linear guide rail slider 10, a straightening U-shaped linear guide rail 11, a straightening screw nut 12, a straightening screw 13, Set the telescopic servo motor adapter flange 14, set the telescopic servo motor coupling 15, and set the telescopic servo motor 16. The straightening fixed base plate 17 is fixedly connected, and is connected with the straightening screw 13 through...

Embodiment 3

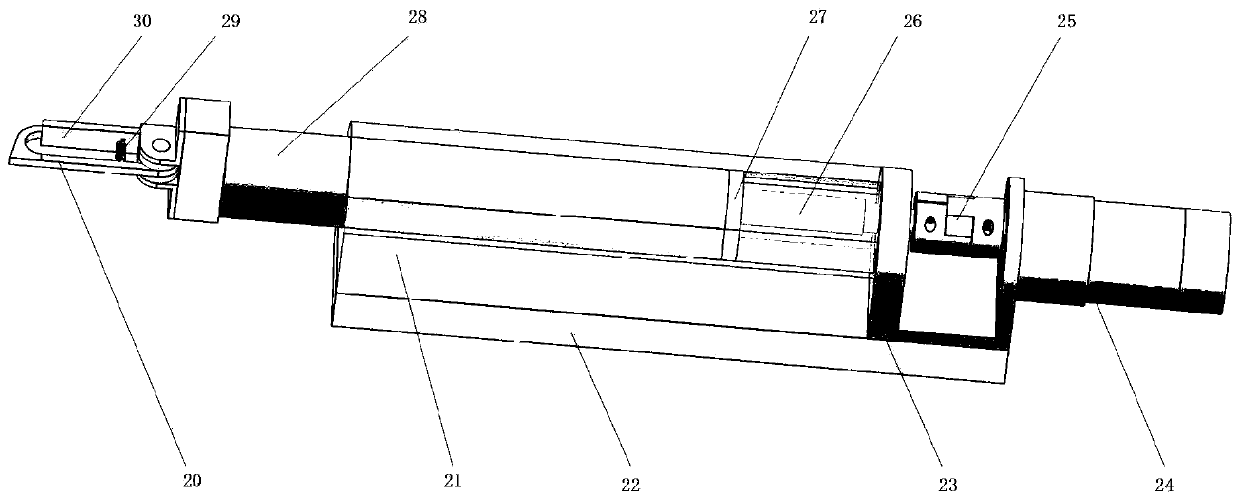

[0042] Such as image 3 as shown, image 3 It is a structural schematic diagram of the insulator pin pulling device. The insulator pin pulling device includes a pin pulling telescopic assembly and a pin removing hook; the pin removing hook is used to hook the iron pin in the iron cap of the insulator, and the insulator pin pulling telescopic assembly is used to extend or retract the pin removing hook .

[0043] Specifically, the insulator pin-pull telescopic assembly includes a pin-pull U-shaped linear guide rail 21, a pin-pull fixed base plate 22, a pin-pull telescopic servo motor adapter flange 23, a pin-pull telescopic servo motor 24, and a pin-pull telescopic servo motor coupling Device 25, pin-pull leading screw 26, pin-pull leading screw nut 27, pin-pull U-shaped linear guide rail slide block 28.

[0044] The pin-pull telescopic servo motor 24 is fixedly connected to the pin-pull fixed base plate 22 through the pin-pull telescopic servo motor adapter flange 23, and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com