Hydraulic simulation test bench for semi-vehicle active suspension system

A technology that simulates test benches and active suspensions. It is used in vehicle suspension/shock absorber testing, vibration testing, and machine/structural component testing. The effect of mechanical friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

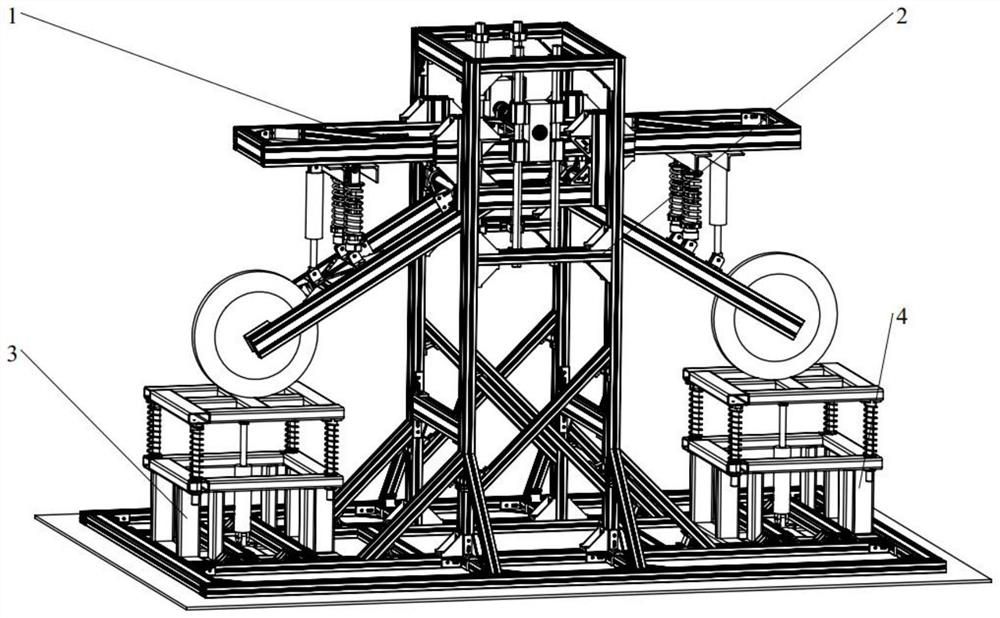

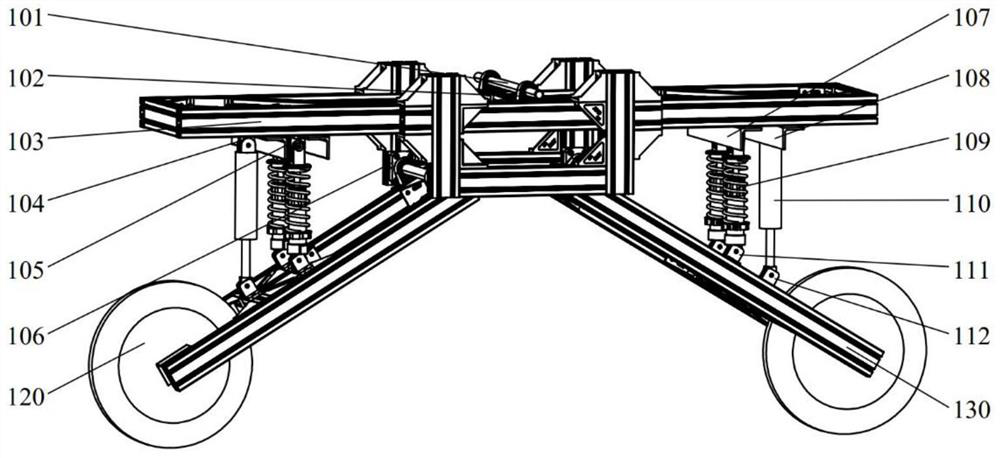

[0037] Embodiment 1: as Figure 1-17 As shown, a half-vehicle active suspension system hydraulic simulation test bench includes a half-vehicle simulation bench 1, a half-vehicle guide frame 2, a front hydraulic system simulation excitation table 3, and a rear hydraulic system simulation excitation table 4; The simulated platform 1 is supported on the front hydraulic system simulated vibration table 3 and the rear hydraulic system simulated vibration table 4 through the front and rear wheels 121; the front hydraulic system simulated vibration table 3 and the rear hydraulic system simulated vibration table 4 Fixed on the bottom frame 202 of the semi-vehicle guide frame 2 by the fixed rod 218 of the excitation table; Realize the movement of the semi-vehicle simulation platform 1 in the vertical direction and the pitch direction.

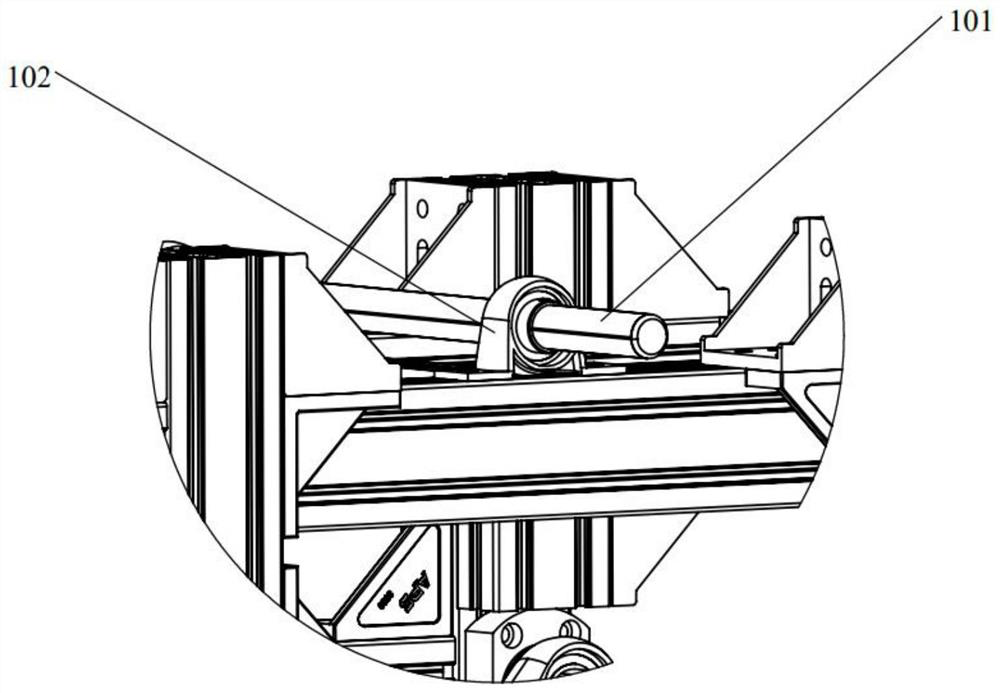

[0038] Optionally, the semi-vehicle simulation platform 1 has a front-rear symmetrical structure, including a carrier 103, two groups of wheel assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com