Cast-in-place concrete floor thickness detection method and structure

A technology of thickness detection and concrete, which is applied in the direction of electric/magnetic thickness measurement, measuring device, electromagnetic measuring device, etc., can solve the problems that the detection point cannot be detected, the position of the electromagnetic signal emitted by the transmitting probe cannot be guaranteed, and the floor evaluation cannot be performed. Achieve the effects of improved orderliness and simplicity of operation, improved effectiveness, and standardized layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to facilitate those skilled in the art to better understand the technical solutions of the present invention, the specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings. To limit the present invention.

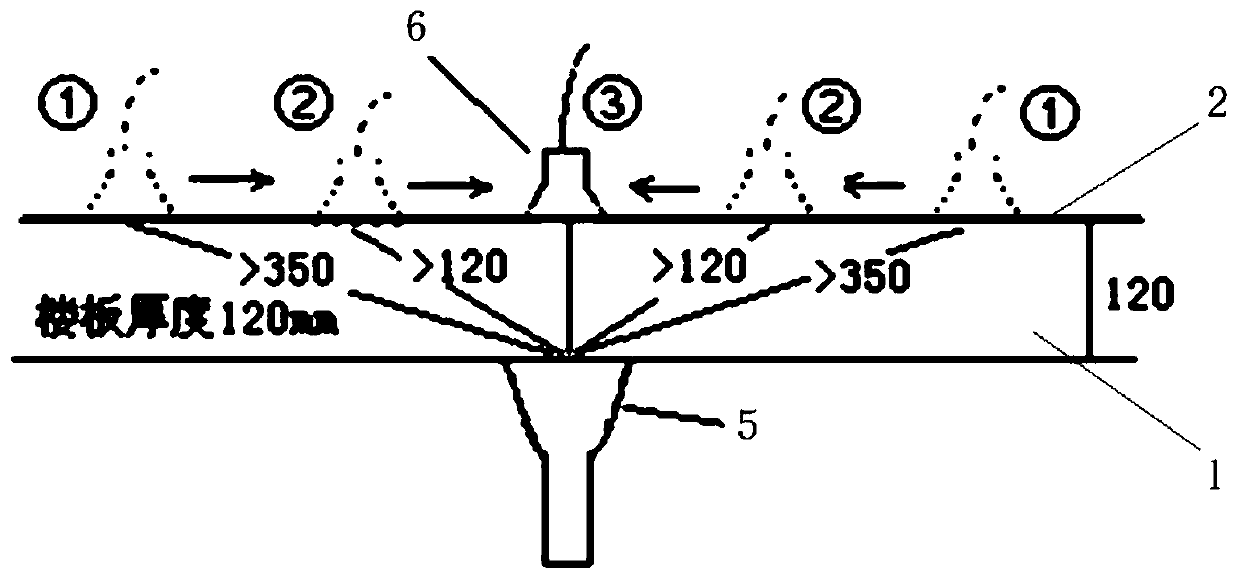

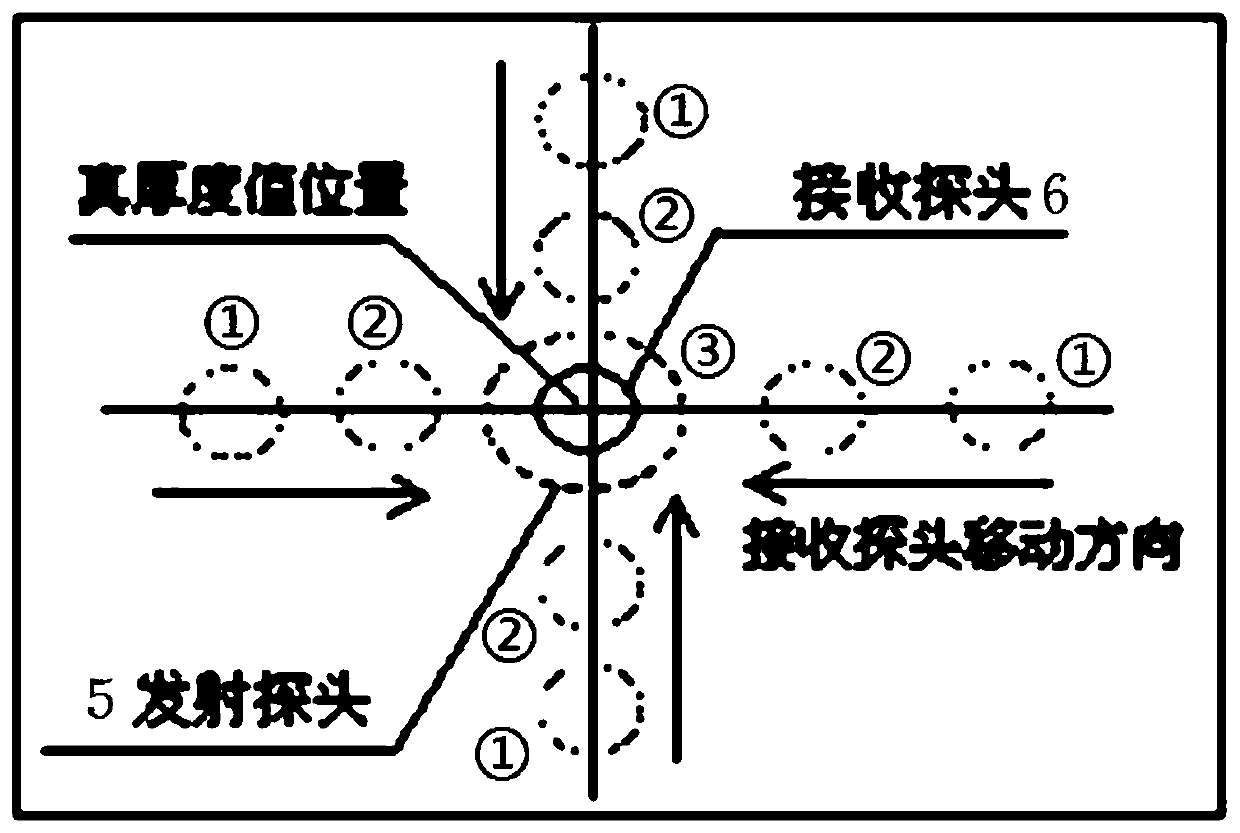

[0023] like Figure 2-3 As shown, the present invention provides a cast-in-place concrete floor thickness detection structure, the detection structure includes a floor to be detected 1, a detection grid 2 is set on the floor to be detected, and the detection grid 2 includes all determined detection points 3 and detection points The nearby detection path 4; the horizontal distance between the detection points 3 is not less than 350mm, the transmitting probe 5 is arranged under the floor 1 to be detected, and the receiving probe 6 is arranged above the floor 1 to be detected, and the transmitting surface of the transmitting probe 5 is larger than that of the receiving probe 6 In this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com