Self-adaptive vehicle vibration damper based on stepless regulation

A stepless adjustment and self-adaptive technology, applied in the field of vehicle engineering, can solve the problem that the shock absorber cannot automatically adjust the damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

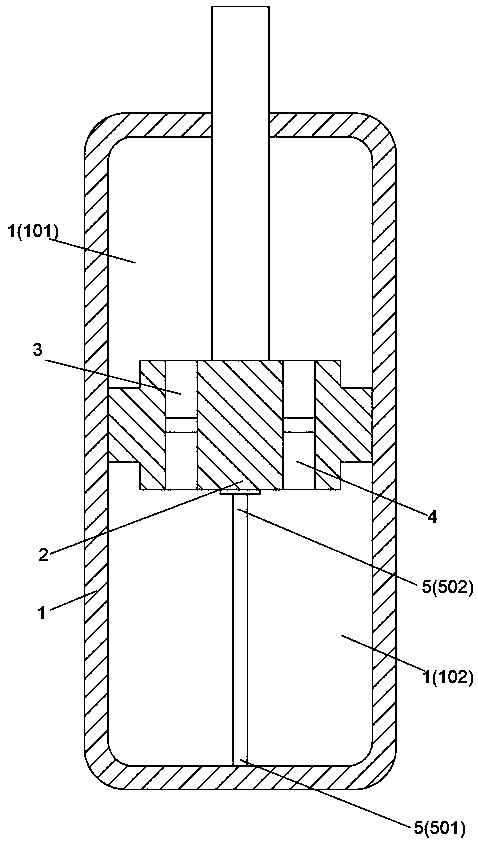

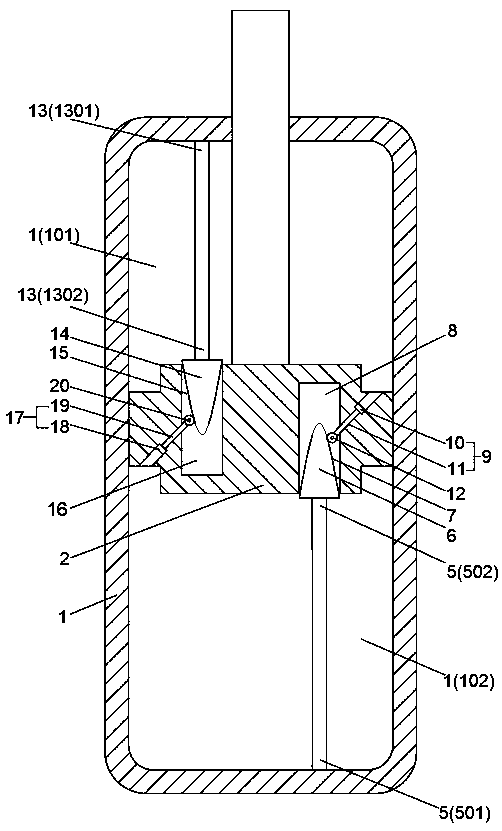

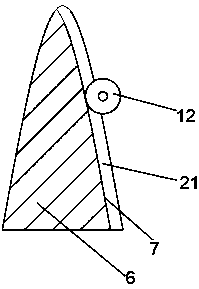

[0039] figure 1 It is a structural schematic diagram (1) of an adaptive vehicle shock absorber based on stepless adjustment provided according to an embodiment of the present invention, as shown in figure 1 As shown, the adaptive vehicle shock absorber based on stepless adjustment in this embodiment includes: a working cylinder 1; a piston unit including a connected piston 2 and a piston rod 3, wherein the piston 2 is arranged on the working cylinder 1, the piston rod 3 extends to the outside of the working cylinder 1 through the upper end of the working cylinder 1; the working cylinder 1 includes a first chamber 101 and a second chamber 102, wherein the first chamber 101 is located between the piston 2 and the Between the upper end of the working cylinder 1, the second chamber 102 is located between the piston 2 and the lower end of the working cylinder 1, and damping fluid is filled between the first chamber and the second chamber; A first one-way valve 3 and a second one-w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com