Temperature control method for material barrel of precision injection molding machine

A technology of barrel temperature and control method, applied in the field of temperature control, can solve the problems of long time and waste the production time of manufacturers, and achieve the effect of sacrificing time efficiency, high control precision, and simple and fast control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] Embodiment: a precision injection molding machine cylinder temperature control method, comprising the following steps:

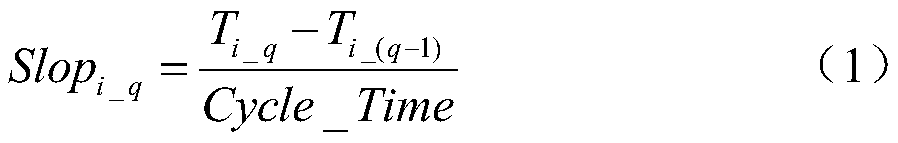

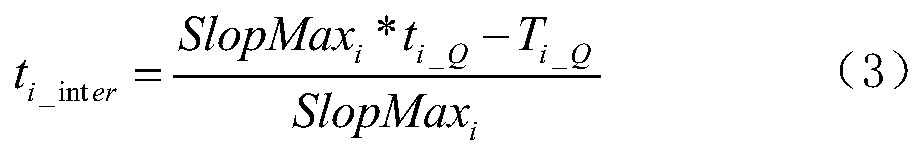

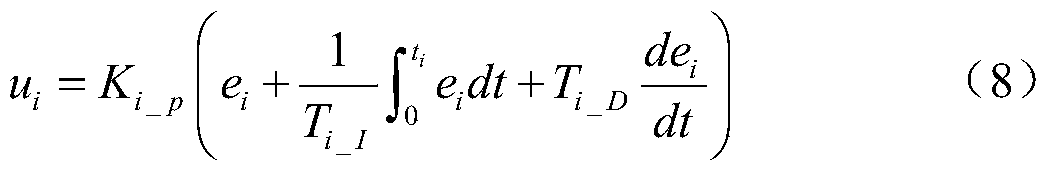

[0034] Step 1. Set a power circle for heating the temperature section and a temperature sensor for collecting the temperature of the temperature section in each temperature section of the barrel of the precision injection molding machine. Each sensor and each power circle are connected with the precision injection molding machine. The controller is connected, and the parameters are set in the controller of the precision injection molding machine to obtain the temperature control cycle and the temperature control cycle. The parameter acquisition temperature control cycle is recorded as Cycle_Time, and the temperature control cycle is recorded as Cycle_Time1. The value of Cycle_Time is 6-13 second, the value of Cycle_Time1 is equal to Cycle_Time, and the maximum heating power of the power circle set at the i-th temperature segment is recorded as u max_i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com