Automatic nozzle and submerged arc welding machine and control system

A technology of submerged arc automatic welding machine and control system, which is applied in arc welding equipment, manufacturing tools, welding rod characteristics, etc., can solve the problems of long preparation time before welding, low degree of automation, poor welding quality, etc., and achieves a simple and clear program structure. , The effect of reducing procurement costs and technical level requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing:

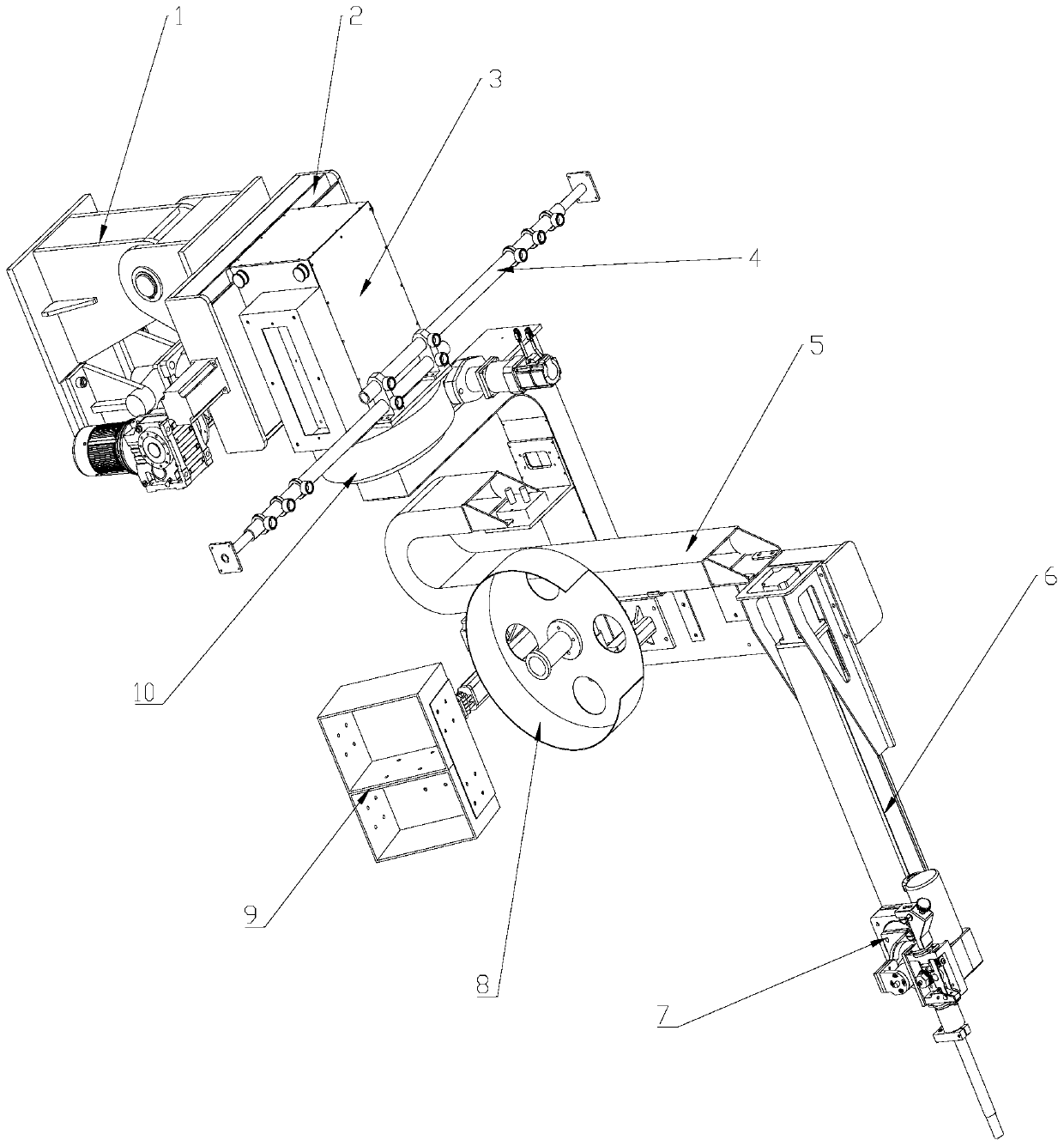

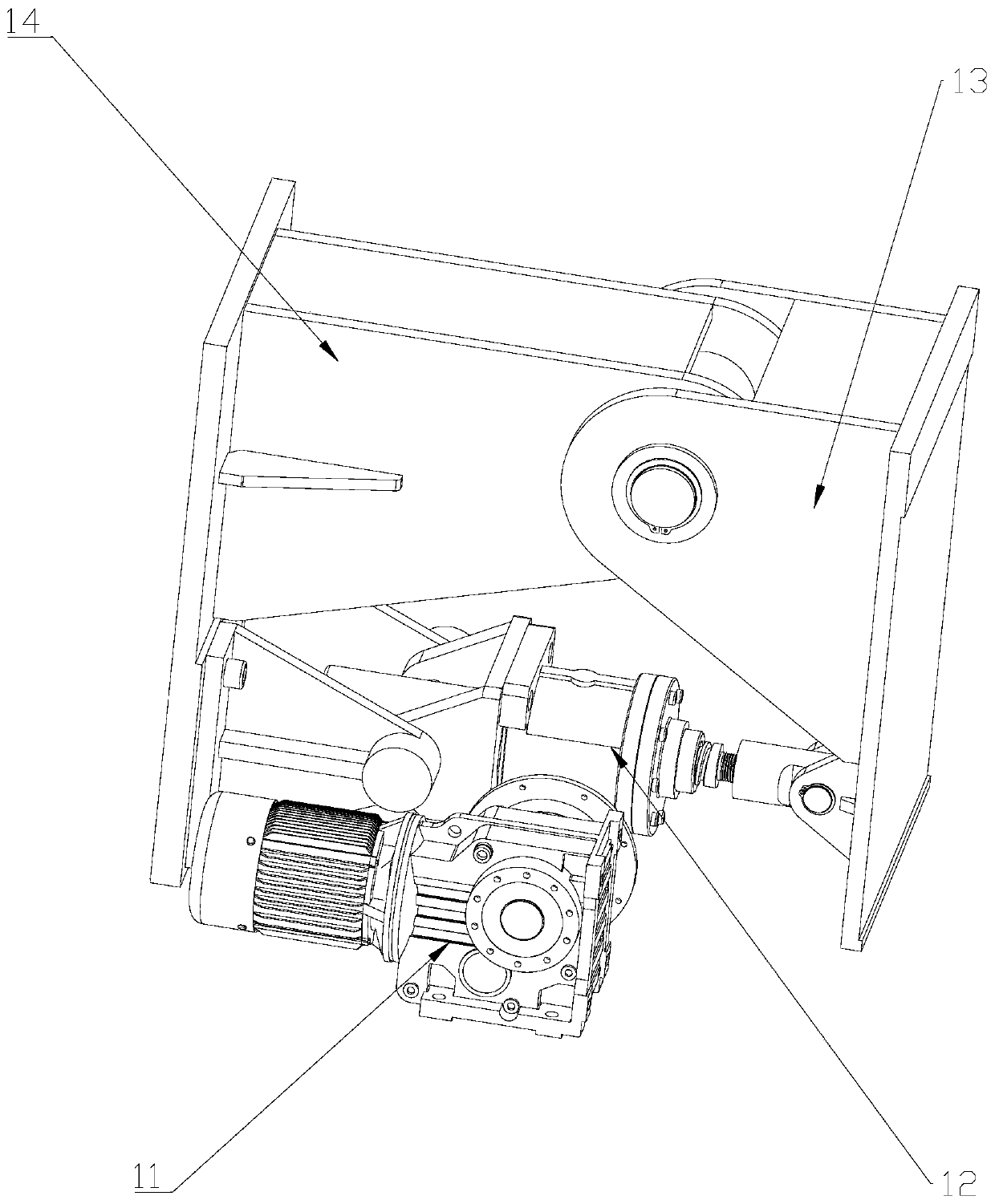

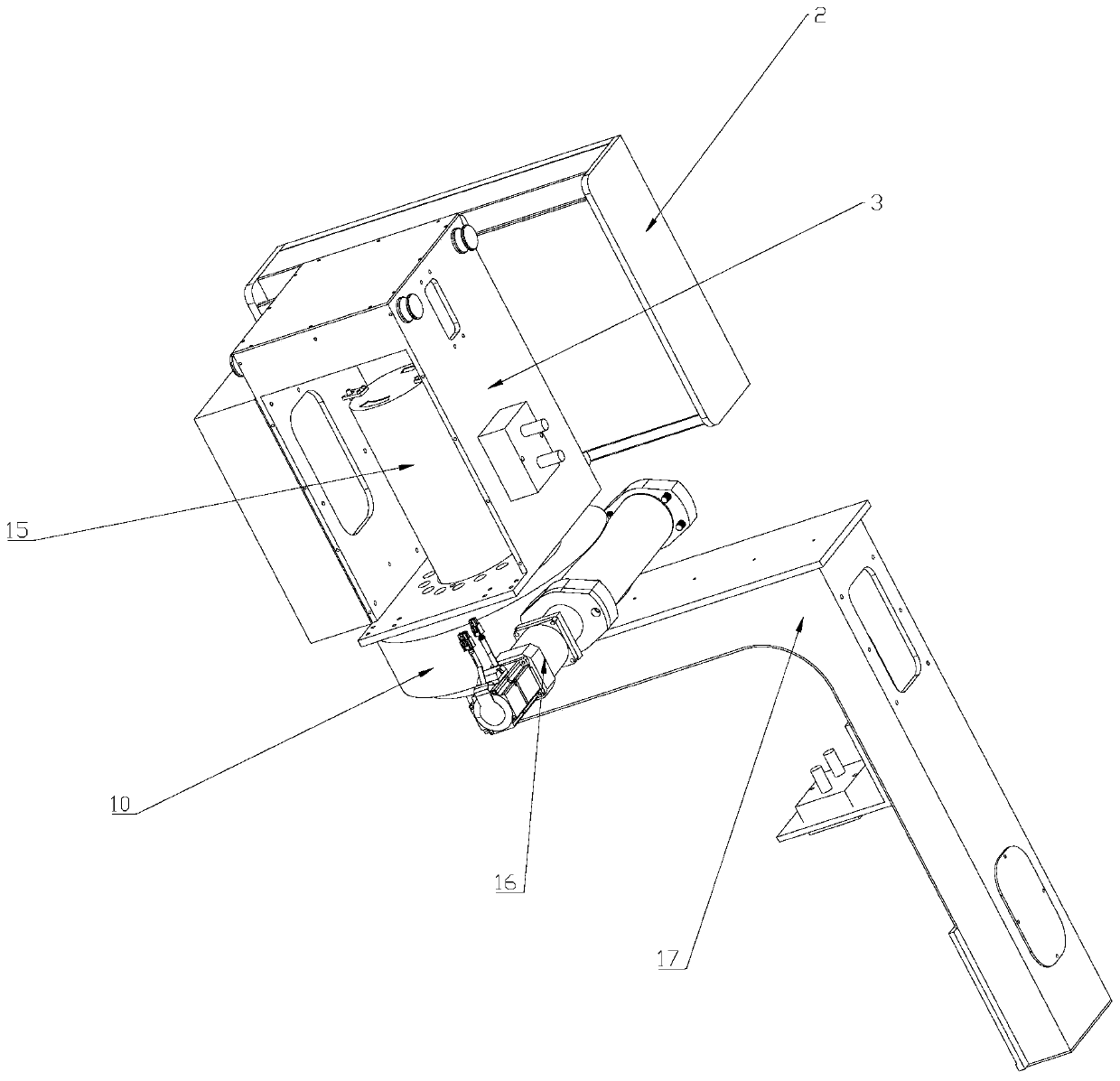

[0038] Such as figure 1 , The automatic submerged arc welding machine of the present invention mainly includes an aligning mechanism 1, a rotary support 3, a rotary system 10, a horizontal movement unit 2, a vertical movement unit 6, a wire feeding unit 7, a remote operation control box 9, a welding wire reel and Mechanisms such as its mounting bracket 8, lighting unit 4, drag chain annex 5 and other annexes. One side of the horizontal motion unit 2 is connected with the centering mechanism 1, and the other side is connected with the slewing support 3, the slewing system is installed at the lower part of the slewing support 3, the drag chain attachment 5 is connected with the lower part of the slewing system, the welding wire reel and its mounting bracket 8 . The remote operation control box 9 is fixed on the bracket of the drag chain attachment 5, the front end of the dra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com