Defect inspection device and method

A defect inspection and inspection result technology, which is applied in the field of defect inspection devices and methods, can solve the problems of position measurement circuit data output interval size error, insufficient to meet system requirements, and cannot generate timing pulses with sufficient precision, etc., to achieve image resolution The effect of improving the rate and improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

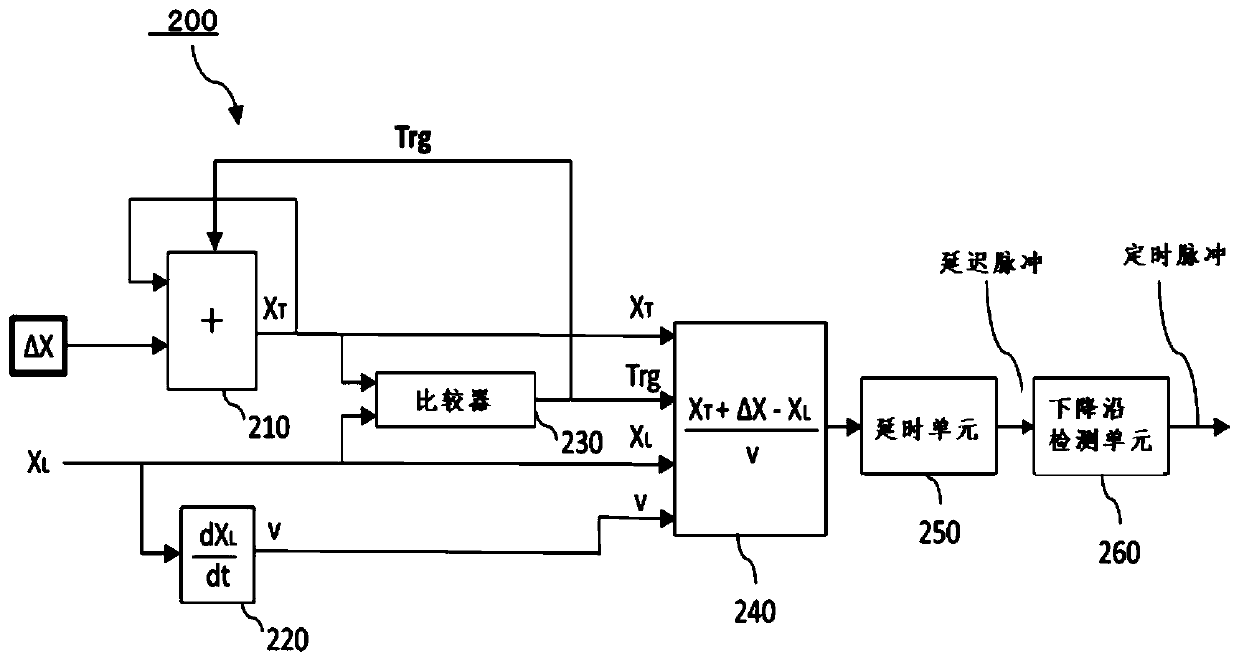

[0075] see Figure 4 , Figure 4 Shown is a timing diagram for explaining each pulse according to the present embodiment. In this embodiment, the location information X L The update frequency is 10MHz. Therefore, location information X L The acquisition times can be at equal intervals of 100 nanoseconds. A carriage (such as the X carriage in this embodiment) can be set to move one pixel at intervals of approximately 333 nanoseconds.

[0076] Ideally, the timing pulse output time should be issued when moving one pixel. Express it as the original timing pulse output time in Figure 4 .

[0077] Because in the prior art, the output time of the comparator is used as the timing pulse, therefore, there will be an error M between the original timing pulses. The error M is equivalent to causing blur of 1 / 3 pixel. The goal in this example is to reduce this to about 1 / 10 to 1 / 100.

[0078]Therefore, in this embodiment, conventional timing pulses need to be delayed by one clock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com