High-voltage relay ceramic closed cavity structure, high-voltage relay and its working method

A high-voltage relay, closed cavity technology, applied in relays, electromagnetic relays, electromagnetic relay details, etc., can solve the problems of unreliable contact and failure of relays, and improve the ability to resist extreme large current shocks and reverse voltage capabilities. , to ensure the effect of contact reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment one (comparative example):

[0048] Examples of arc extinguishing work for existing relays:

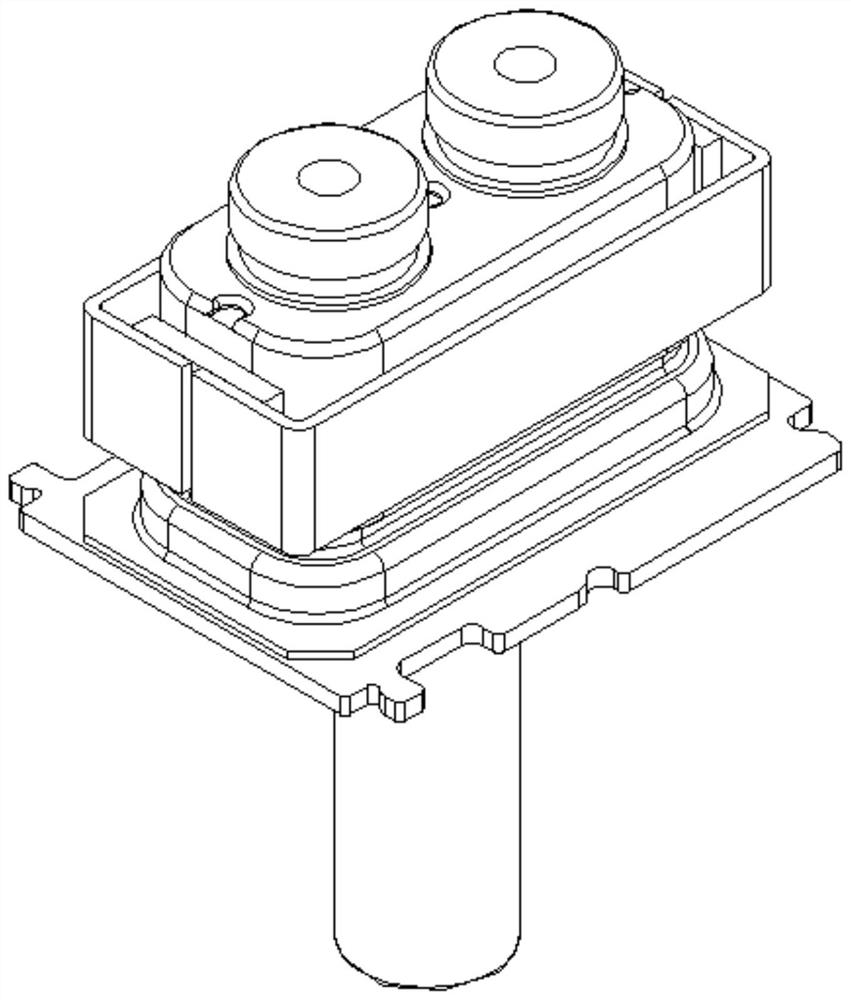

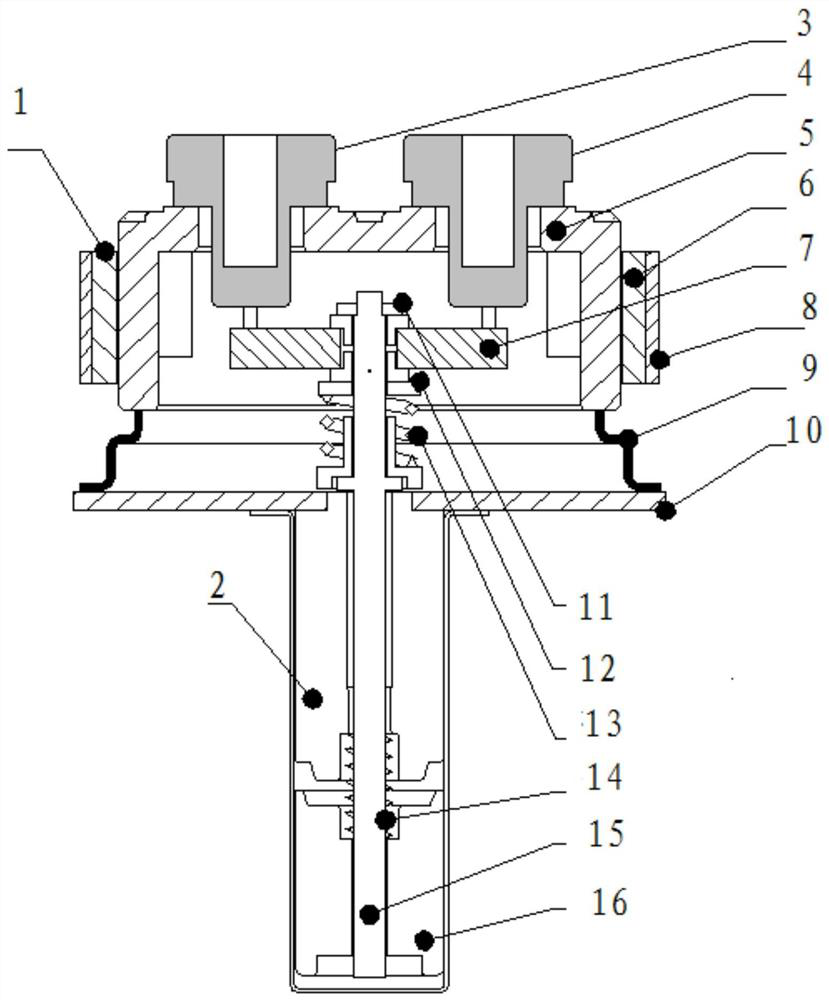

[0049] For the convenience of introduction, the structure here is simplified, see Figure 3-6 : The permanent magnets of existing products are arranged on both sides of the contact point rod in the Y direction, such as Figure 3-4 Shown, the arc extinguishing magnetic field produced by the permanent magnet, continue to refer to Figure 5-6 , when the external high-voltage and high-current load of the relay flows forward as shown in the figure, the arc between the contact piece and the contact rod is pulled to both sides of the contact rod according to the left-hand rule under the action of the magnetic field formed by the permanent magnet , in order to achieve the purpose of thinning the arc and extinguishing it quickly, such as Figure 6 shown; on the contrary, as Figure 7-8 As shown, if the external high-voltage and large current is reversed, that is, when it ...

Embodiment 2

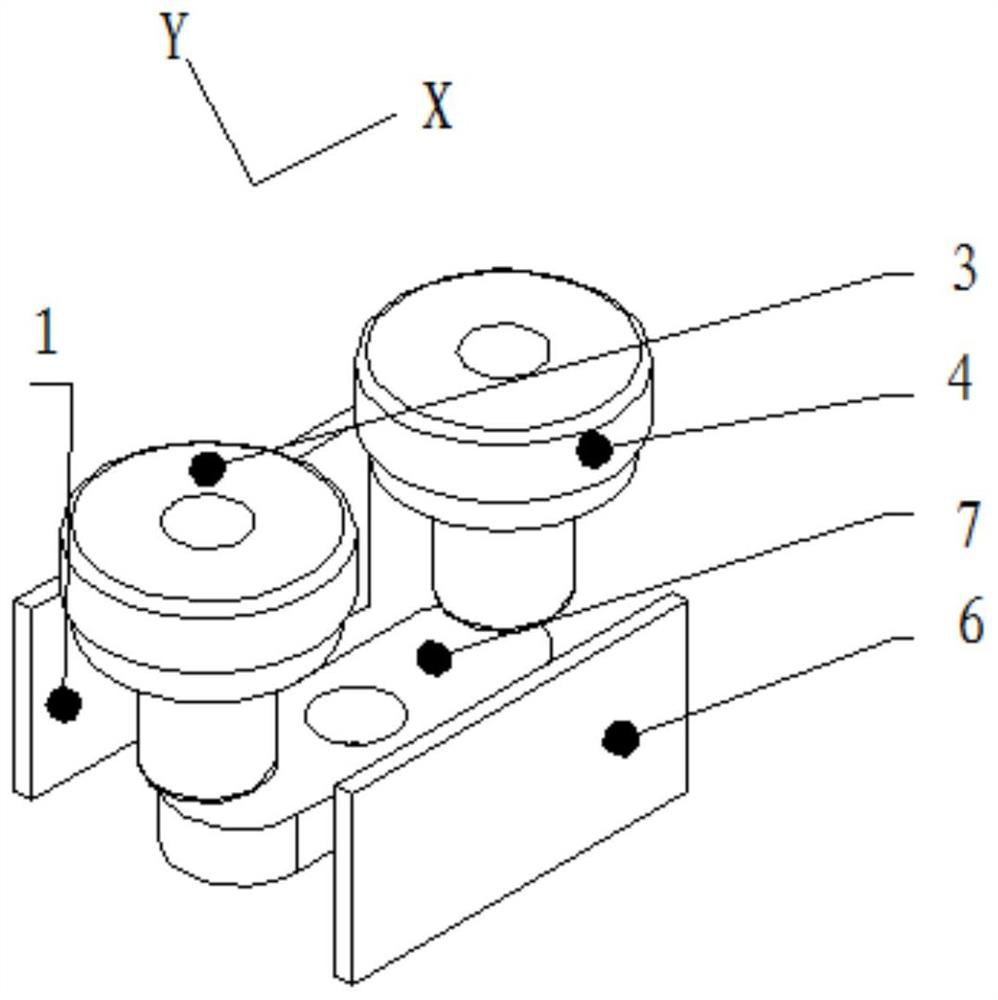

[0053] For the convenience of introduction, the structure here is simplified, see Figure 9-13 :

[0054] The relay sets its permanent magnets on the left and right sides of the contact rod in the X direction, such as Figure 10 As shown, the arc extinguishing magnetic field produced by the permanent magnet is as follows Figure 9 As shown, when the external high-voltage and high-current load of the relay is pressed Figure 12 In the forward direction, the arc between the contact piece and the contact rod is under the action of the magnetic field formed by the permanent magnet. According to the left-hand rule, the arc of the left contact rod 3 is pulled to the left, and the arc of the right contact rod 4 is pulled to the left. The arc is pulled to the right to achieve the purpose of thinning the arc and extinguishing it quickly, such as Figure 11-13 Conversely, if the external high-voltage and large current is reversed, the arc of the right contact rod 3 is pulled to the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com