Optical product automatic locking stud machine

An automatic lock and product technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of unguaranteed product quality, unable to meet production needs, low degree of automation, etc., to ensure product production quality, save money The effect of removing the clipping process and facilitating the recycling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical solutions and beneficial effects of the present invention clearer, the preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so as to facilitate the understanding of technical personnel.

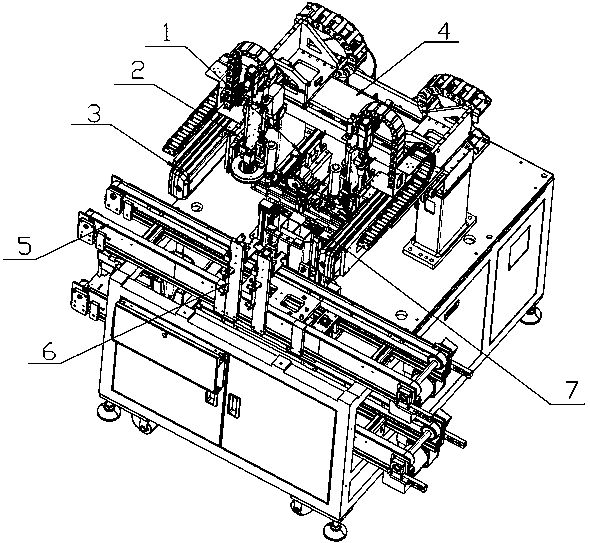

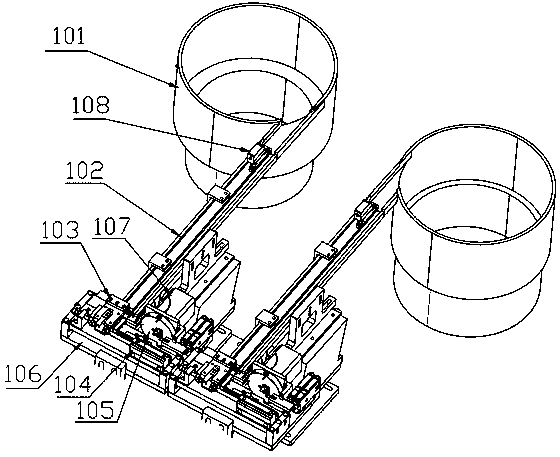

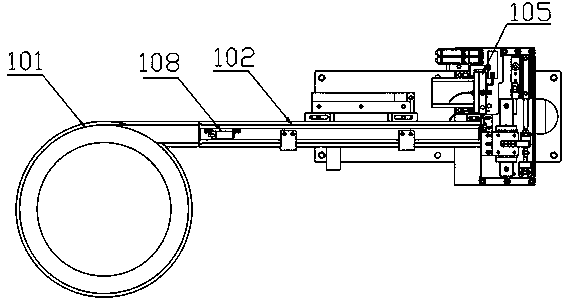

[0031] Such as Figure 1 to Figure 12 As shown, the automatic locking stud machine for optical products includes a stud feeding device 1, a locking device 2, and a product feeding device 5, and the product feeding device 5 is arranged on the outlet side of the feeding device 1, and the feeding device 1 and the product A locking device 2 is arranged between the feeding devices 5 . The locking device 2 includes an installation backplane 201, a vertical slide rail 202, a vertical slider 203, an electric batch 204, an electric batch connecting rod 205 and an electric batch driving cylinder 206, and the installation backplane 201 is fixedly installed on the longitudinal slideway 3 , th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com