Method for vacuum-distilling and aging brewage, and alcoholic beverage

A distillation method and technology for alcoholic beverages, applied in the field of alcoholic beverages, can solve the problems of being unsuitable for long-term aging, and achieve the effect of short time required, less energy, and increased alcohol concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

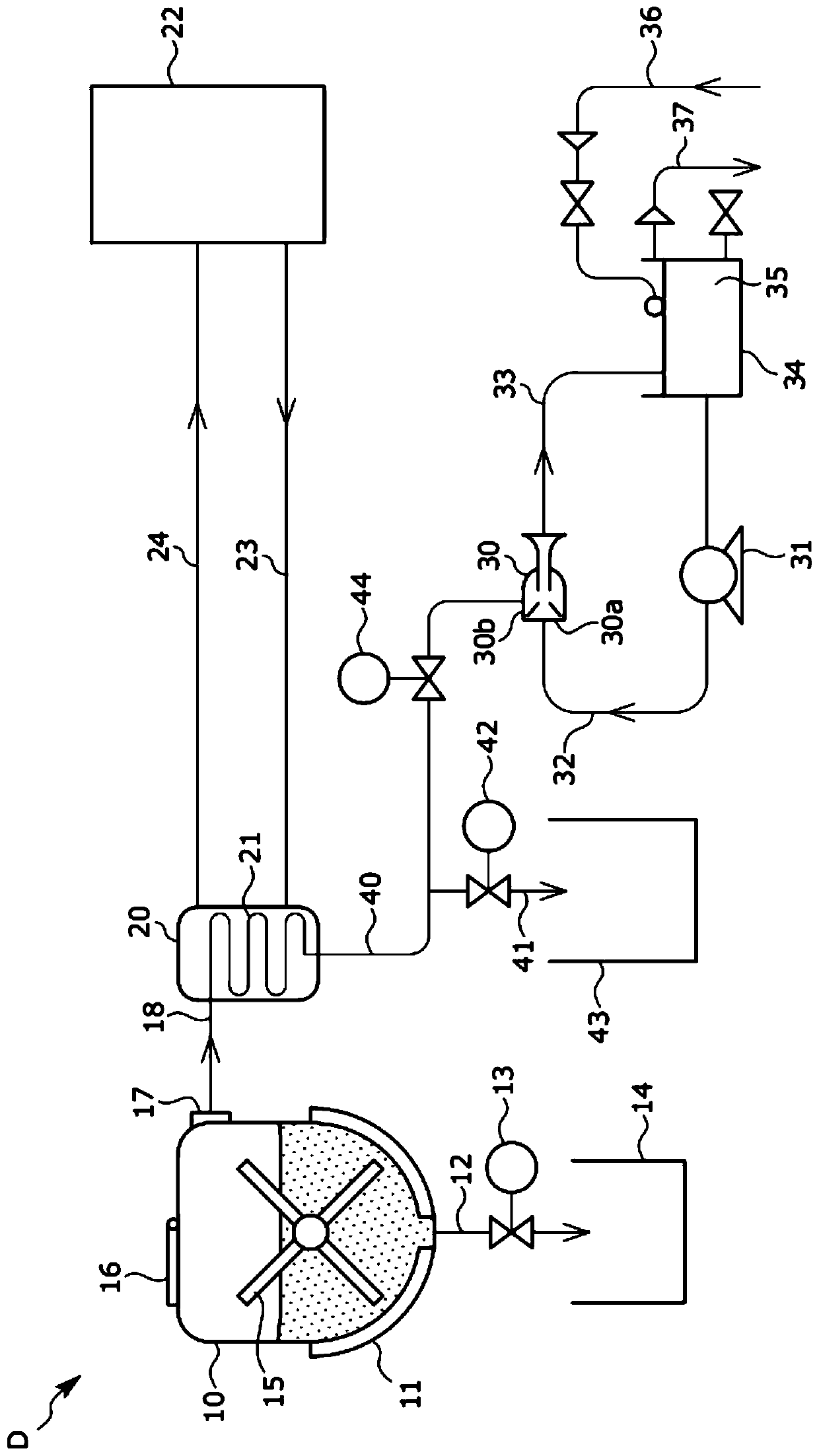

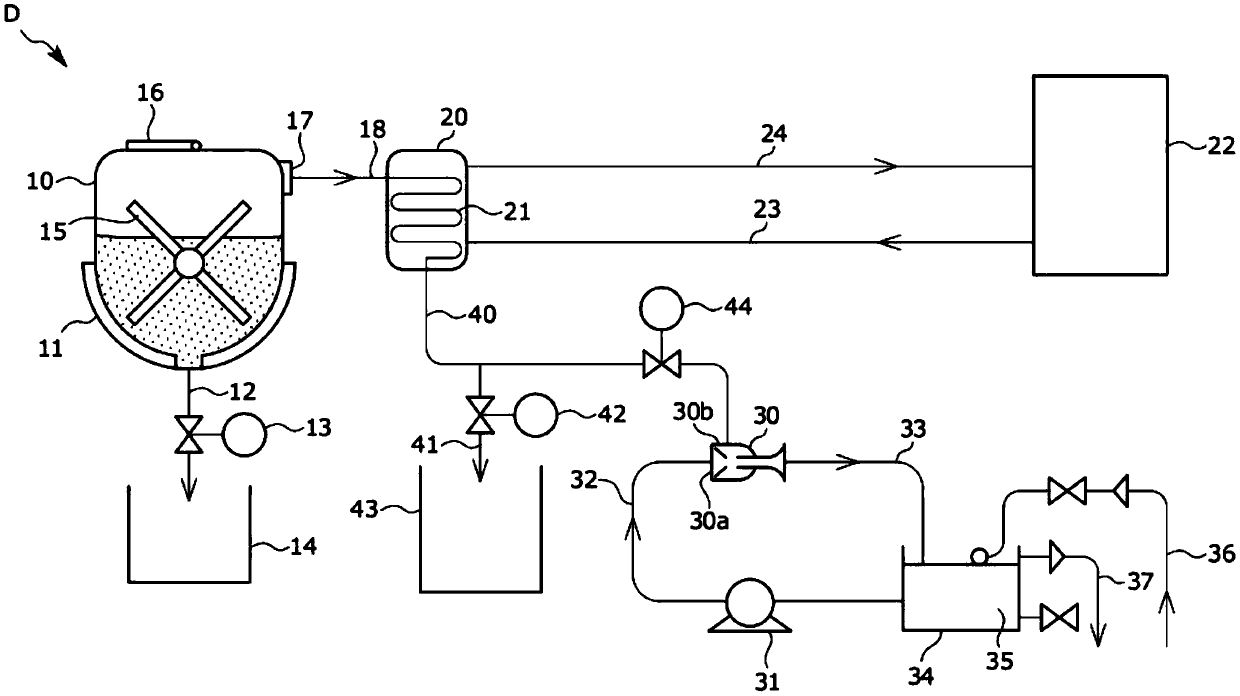

Method used

Image

Examples

Embodiment 1

[0096] A vacuum drying device (manufactured by F·E·C Co., Ltd., trade name "Vacuum Dryer FED-50") was used as a vacuum distillation device. 10 L of pre-made sake was put into the container, the pressure was reduced to -98 kPa, and vacuum distillation was performed for 30 minutes at a temperature in the container of 35°C. The recovered condensed water is 2L, and 8L of liquid remains in the container. The recovered condensed water (alcoholic beverage with an alcohol concentration of about 50 degrees) was evaluated.

Embodiment 2

[0098] The condensed water of Example 1 was stored at 20° C. for 12 months for aging. The aged condensate (aged alcoholic beverage) was evaluated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com