A cutting device for tensile and flame-retardant power cable processing

A technology for power cables and cutting devices, which is used in the manufacture of cables/conductors and used to reduce the size of conductors/cables, circuits, etc., can solve the problems of low operation safety, life-long disability, amputation, etc., to protect life safety, The effect of improving safety and reducing accident rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

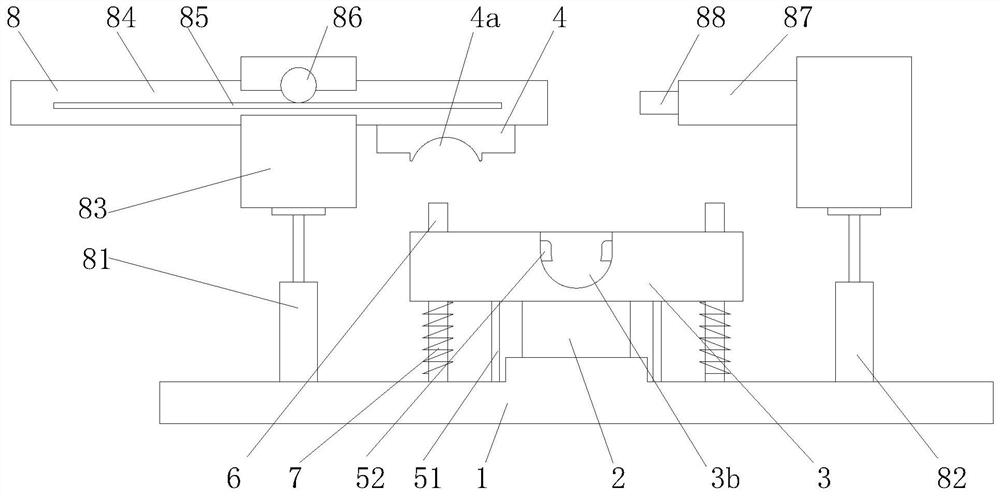

[0019] Such as Figure 1 to Figure 3 A cutting device for tensile and flame-retardant power cable processing is shown, including a base 1, on which a blade 2 with an upward cutting edge is provided; a bearing seat 3, which is movably arranged on the base 1 Above, the top of the bearing seat 3 is provided with a knife-passing hole 3a corresponding to the blade 2 and a cable groove 3b passing through the knife-passing hole 3a; Above the seat 3, the bottom of the press-cut seat 4 is provided with a matching groove 4a corresponding to the cable groove 3b; the unlocking mechanism 5, the unlocking mechanism 5 includes an unlocking lever 51 and two trigger blocks 52, the width direction of the cable groove 3b Both sides of the guide groove 3c are provided, and the two trigger blocks 52 are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com