Transportation whole-course management and control system and method based on Internet of Things

A management and control system and Internet of Things technology, applied in the field of Internet of Things, can solve the problems of unmeasured, counting, data acceptance, inventory management process control, etc., and achieve the effect of avoiding risks and loopholes in the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

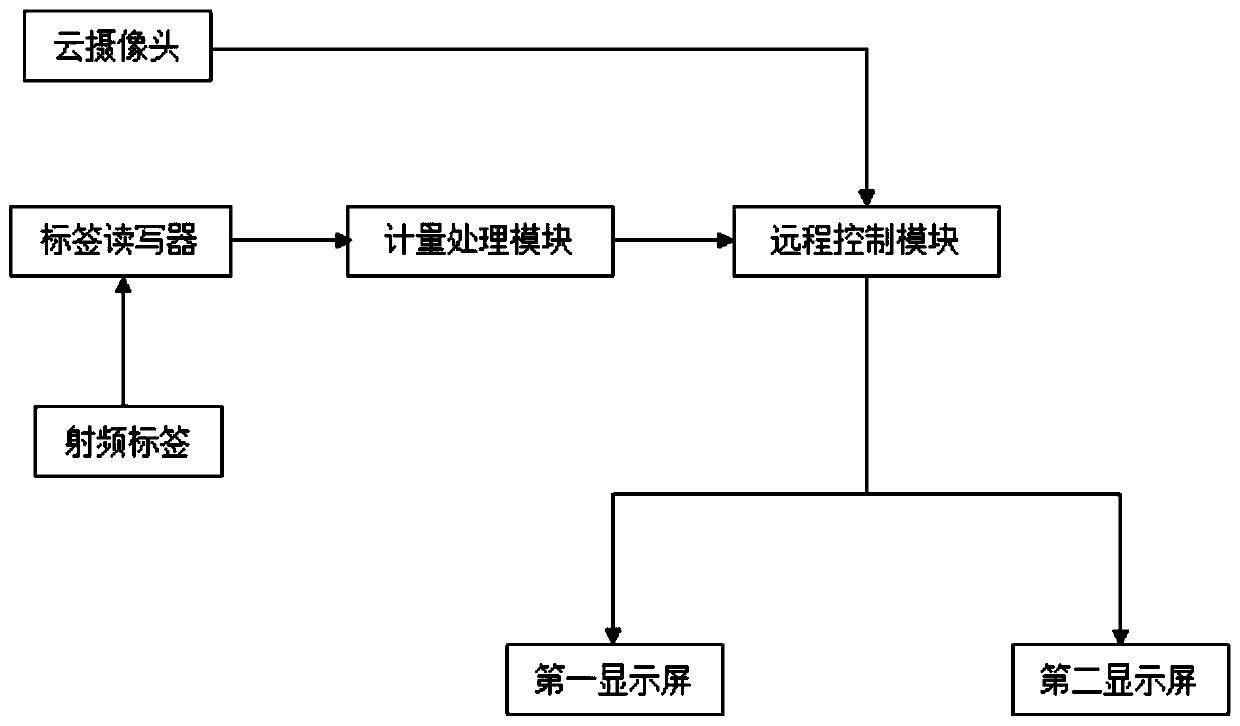

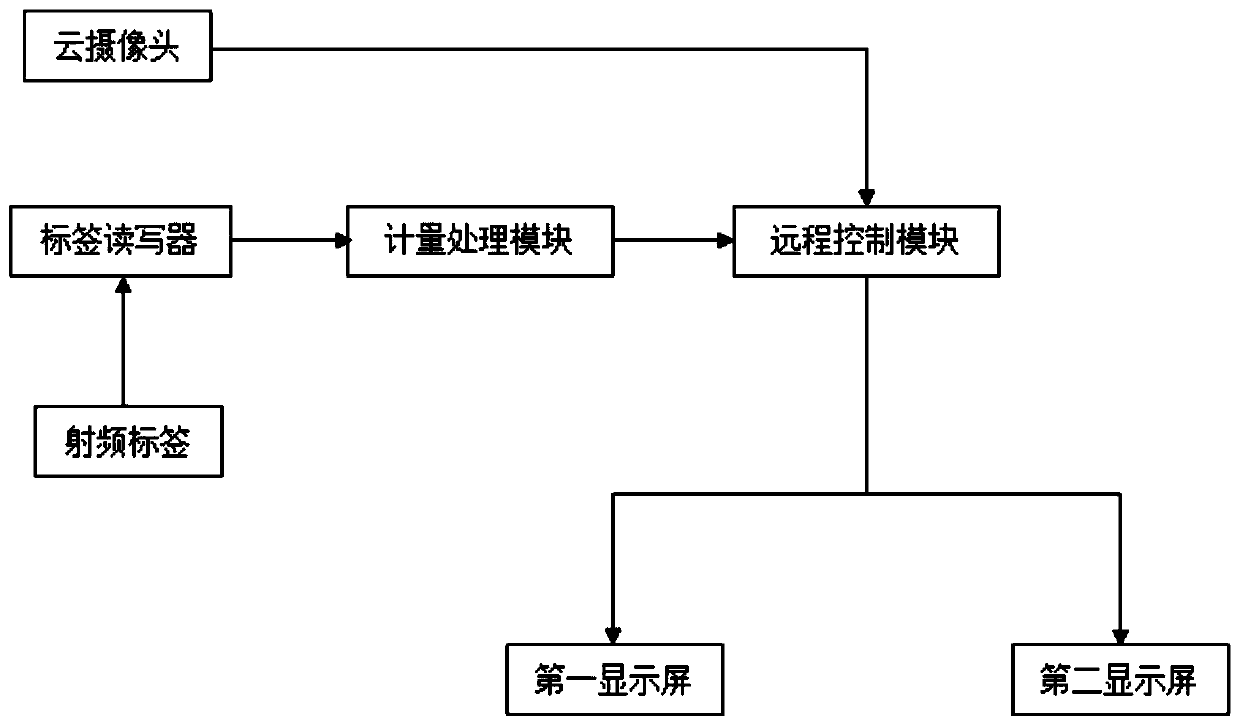

[0027] The embodiment of the transportation management and control system based on the Internet of Things of the present invention is basically as attached figure 1 As shown, it includes a radio frequency tag, a tag reader, a measurement processing module, a remote control module, a first display screen, a second display screen, a GPS positioning device and a cloud camera, (the GPS positioning device is not shown in the figure).

[0028] Radio frequency tags include transport radio frequency tags and cargo radio frequency tags. The radio frequency tag of the means of transport stores information such as the driver's name, license plate number, and the cargo carried, and is installed on the body of the means of transport or the loaded container. The radio frequency label of the goods stores the detailed information of the goods, such as product number, batch number, date, quantity, etc., and is affixed to the corresponding goods. RMU900 label readers are installed at each netw...

Embodiment 2

[0036] The only difference from Example 1 is:

[0037] SAS software is installed on the PC computer of the metering processing module. SAS software organically integrates data access, management, analysis and display, and has the advantages of powerful functions, complete statistical methods, easy to use, flexible operation, and the ability to provide online help functions. It can also realize the accurate classification of cargo data and generate the charts required by the staff, so as to provide the staff with visualized data. The first display screen and the second display screen can be combined into one display screen, one part displays real-time report data, and the other part displays real-time video. In this way, it is more convenient for the staff to view the dynamics of the transportation process at the same time, so that it is easier to find abnormalities in the transportation process of the goods.

Embodiment 3

[0039] The only difference from Example 1 is:

[0040] A pressure sensor is also installed on the transport tool, and the pressure sensor acquires a time-varying curve of the total weight of the transport tool and the transported goods, and sends the change curve to the remote control module.

[0041] Since there are basically deceleration barriers at the entrance and exit of warehouses or various outlets, there will also be situations where the driver brakes or starts quickly. Therefore, due to the action of inertial force, the total weight of the transport tool and the transported goods acquired by the pressure sensor will fluctuate to a certain extent over time. But this range is usually very small, such as within 0.5%; the duration is also very short, such as a few minutes or so.

[0042] When the remote control module detects that the peak of the total weight in the oscillation state exceeds the preset threshold (such as 1%), and the duration is relatively long (such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com