Touch structure, touch display panel and driving method

A touch display panel, touch drive electrode technology, applied in the direction of instrumentation, computing, electrical digital data processing, etc., can solve the problem that continuous touch in the same area cannot be fully detected, the touch report rate is low, and touch drive electrodes cannot be touched Scanning and other issues to achieve the effect of improving the touch reporting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The application will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present application, but not to limit the present application. In addition, it should be noted that, for the convenience of description, only some structures related to the present application are shown in the drawings but not all structures.

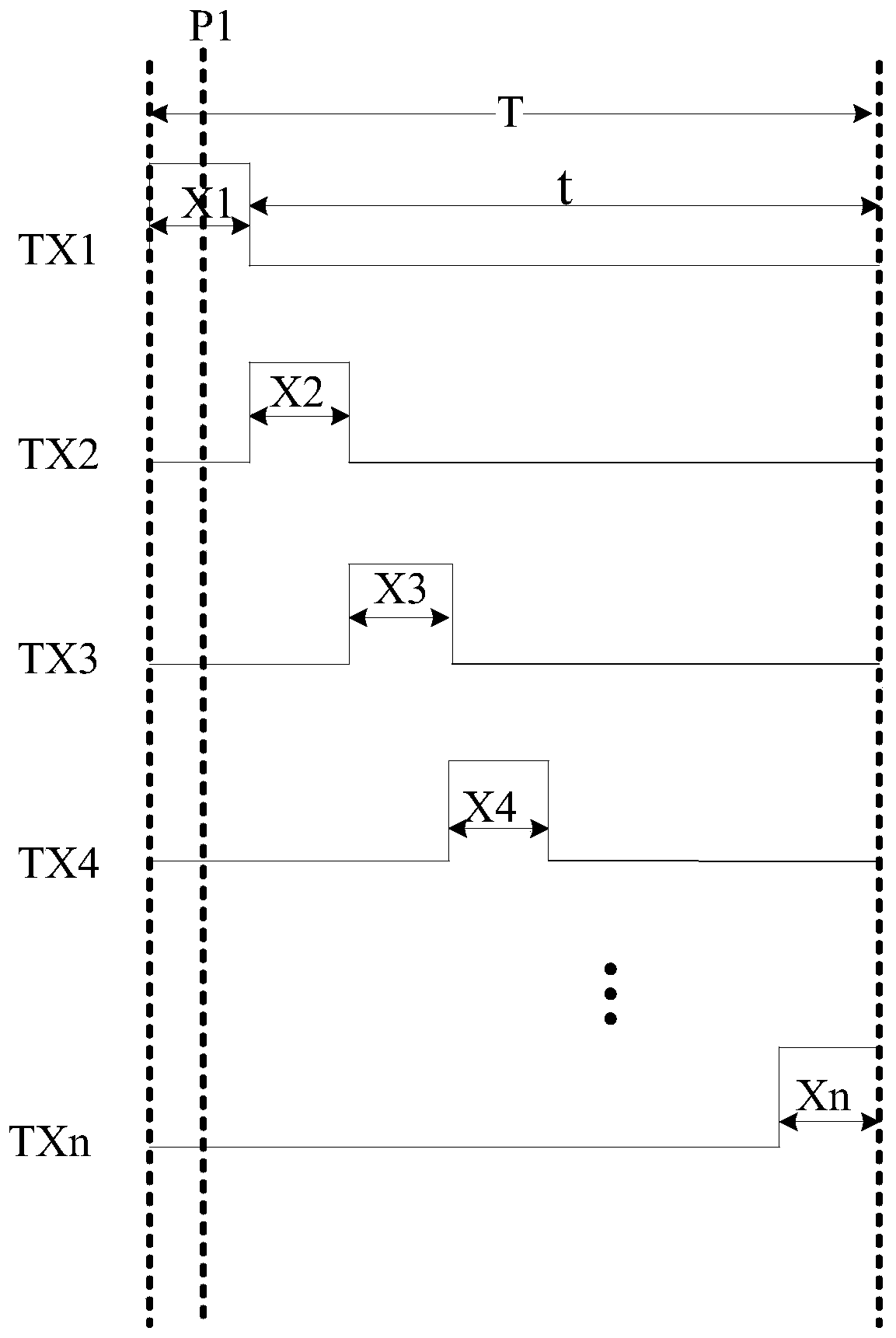

[0034] figure 1 It is a timing diagram of touch drive in the prior art, see figure 1 , figure 1 Exemplarily, the n touch driving electrodes are sequentially marked as TX1 to TXn, wherein n is a positive integer. The first effective driving pulse signal applied to the touch driving electrode TXi is marked as Xi. i is a positive integer greater than or equal to 1 and less than or equal to n. In the touch driving period, the first valid driving pulse signal is provided to the n touch driving electrodes one by one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com