A detachable metal sintered wire mesh noise reduction device

A technology of metal sintering and wire mesh, applied in the direction of pipe components, mechanical equipment, pipes/pipe joints/pipe fittings, etc., can solve the problems of weakened noise reduction effect, reduced noise reduction effect, small low-frequency noise reduction, etc., to achieve noise reduction frequency Wide bandwidth, easy maintenance, and reduced air turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific examples: but the examples are not limitations of the present invention. The content that is not described in detail in the description of the present invention belongs to the well-known technology of those skilled in the art.

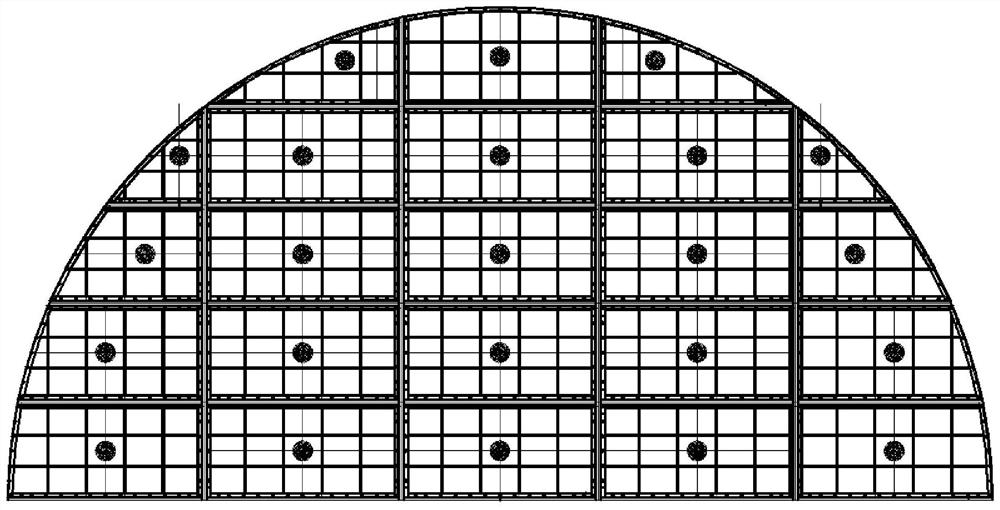

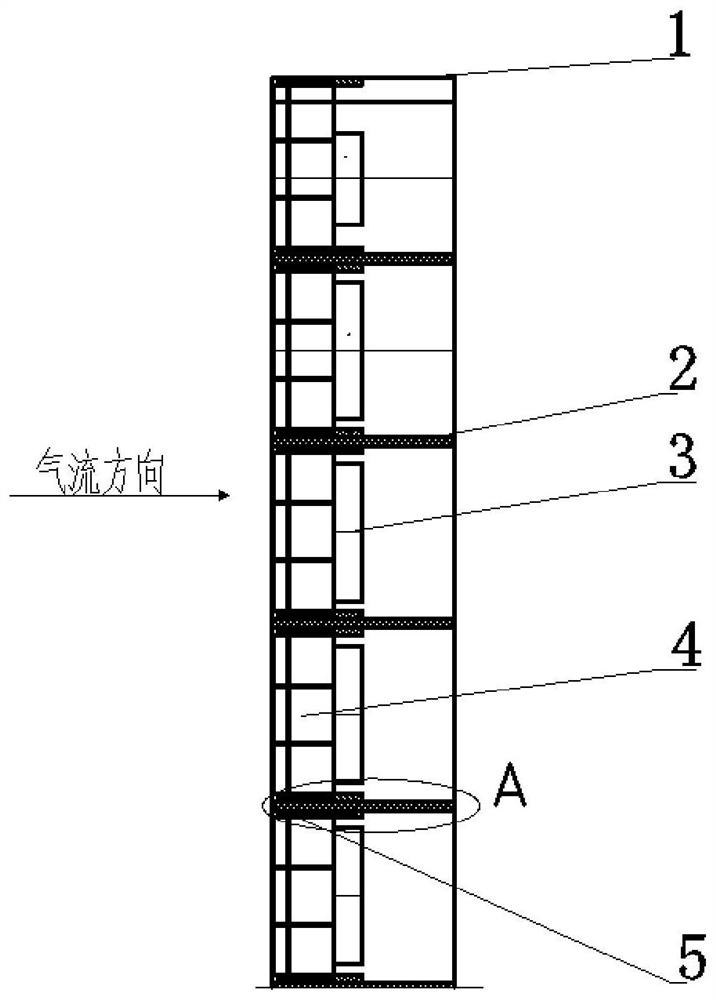

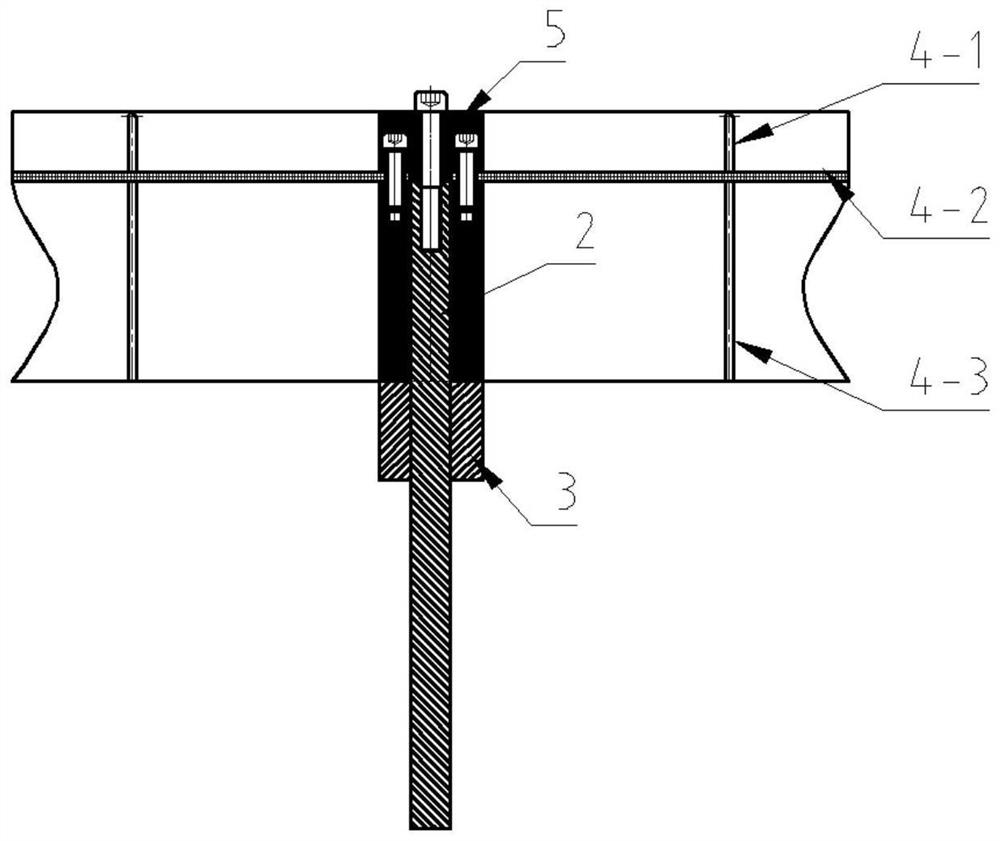

[0034] The metal sintered wire mesh module is installed on the well-shaped frame with a mesh number of one or more layers of 80-160 mesh, optimizing the mesh number of the sintered wire mesh and the number of laying layers, and the noise reduction is between 4dB-15dB. The metal sintered wire mesh module Can be disassembled as a whole, easy to maintain and install. The metal sintered wire mesh is integrally installed and fixed on the well-shaped support frame through concave-convex splicing, which can reduce the structural blocking ratio, and the structural blocking ratio is reduced by about 20%. The metal sintered wire mesh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com