Bent pipeline structure capable of inhibiting flow distortion

A technology of flow distortion and piping, applied to engine components, combustion engines, machines/engines, etc., can solve the problems of increasing flow loss and reducing system efficiency, so as to improve flow, improve system efficiency, and avoid flow mutual interference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0016] The present invention will be described in detail below with reference to the accompanying drawings and examples.

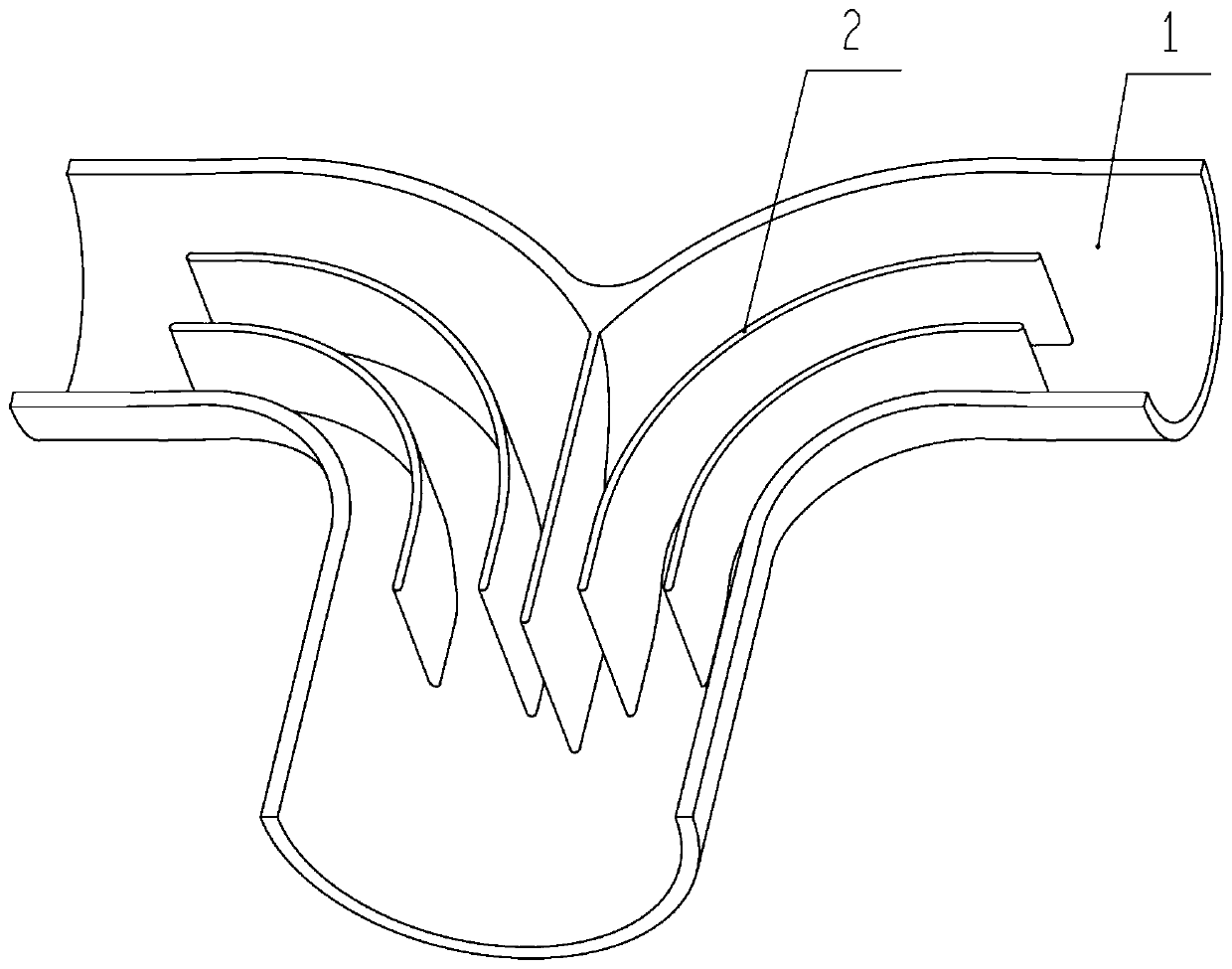

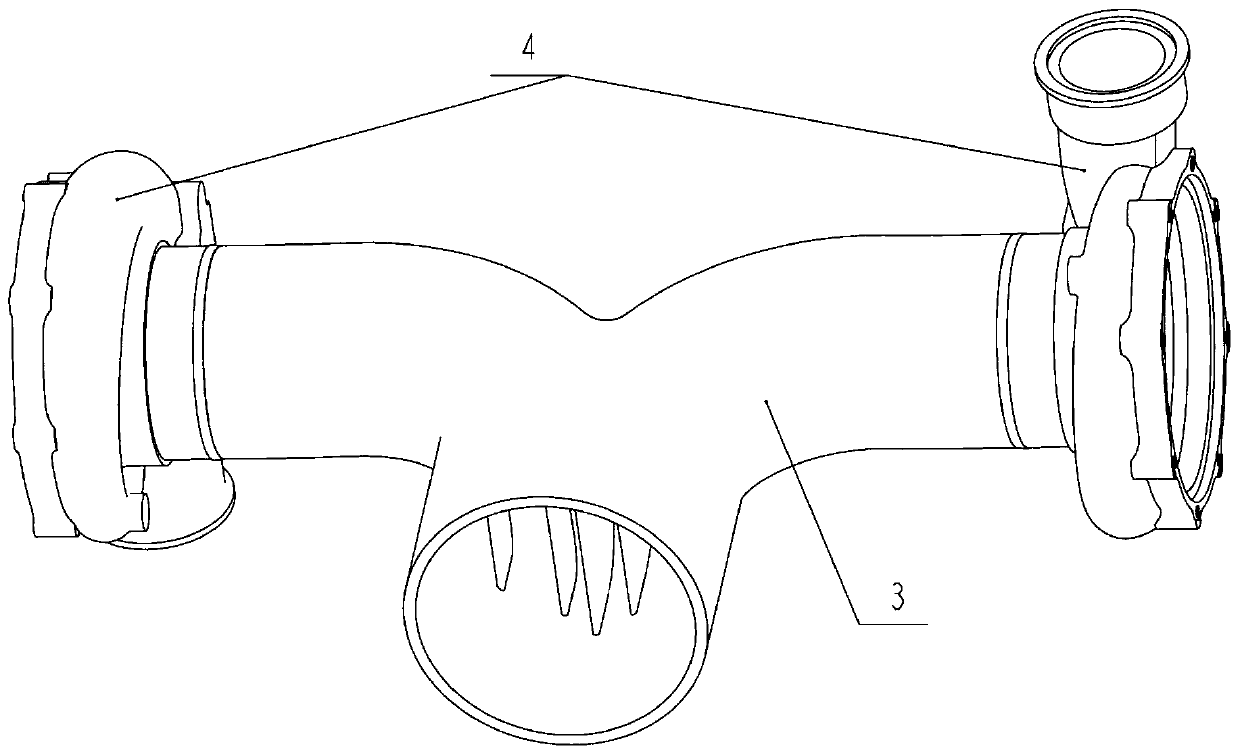

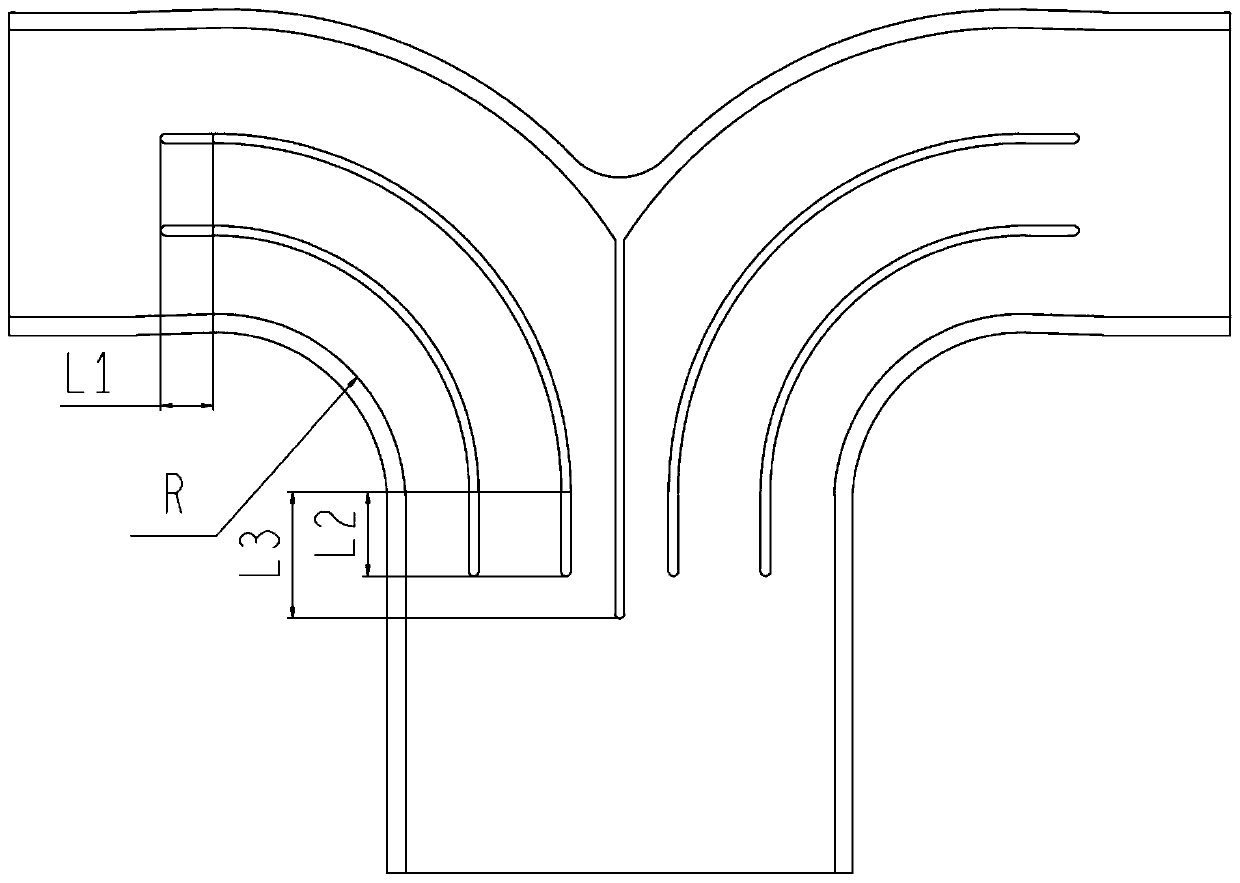

[0017] A curved pipeline structure that suppresses flow distortion, such as figure 1 As shown, it includes a curved pipe body 1. The curved pipe body 1 is composed of a plurality of branch pipes and a main pipe. The inside of the curved pipe body 1 is arranged with guide fins arranged at the junction of the elbow pipes according to the curved shape of the pipeline. 2.

[0018] Arrange one diversion fin 2 at the intersection of two diversion branch pipes, and arrange 1 to 3 diversion fins 2 at the junction of each diversion branch pipe according to the pipe diameter and diversion requirements, such as image 3 As shown, in this embodiment, two diversion ribs 2 are arranged at the juncti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com