Machine furnace deeply coupled thermodynamic system of thermal power generating unit

A technology of thermal power units and thermal systems, applied in the direction of machines/engines, mechanical equipment, steam engine devices, etc., can solve problems such as limited energy saving effects, and achieve the effect of improving power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

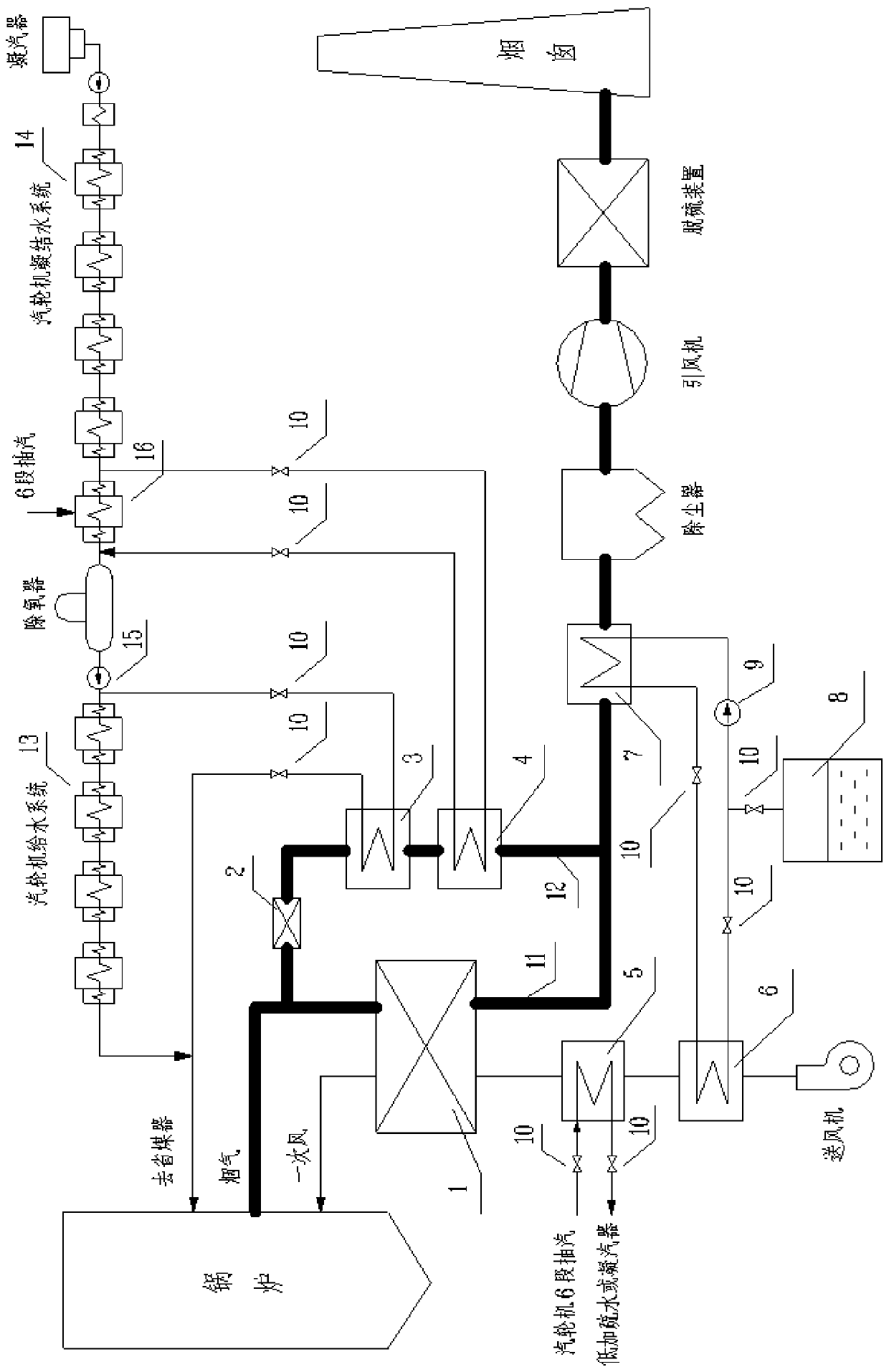

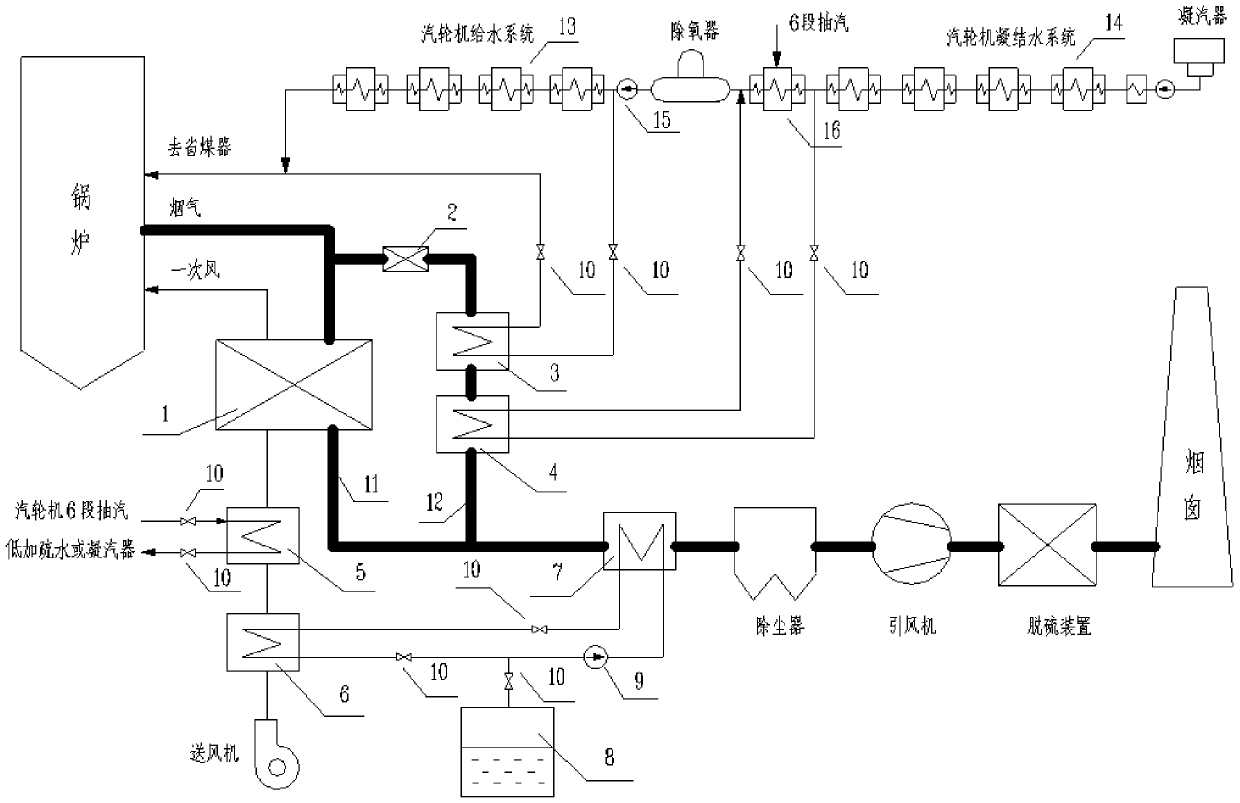

[0022] Such as figure 1 As shown, in this embodiment, a deep coupling thermodynamic system of a thermal power unit includes a boiler, a main flue 11, a dust collector, an induced draft fan, a desulfurization device, and a chimney that are sequentially connected in accordance with the gas flow direction. The flue 11 is connected in parallel with a bypass flue 12, the main flue 11 is provided with an air preheater 1, and the boiler is communicated with a primary air duct capable of exchanging heat with the air preheater 1, and the bypass The flue 12 is provided with a waste heat recovery system.

[0023] The flue gas coming out of the boiler is divided into two paths, one goes into the main flue 11 , and the other goes into the bypass flue 12 . The primary air pipe delivers air to the boiler, and the air in the primary air pipe is preheated by the air preheater 1 , so that the waste heat in the flue gas in the main flue 11 is utilized. The flue gas entering the bypass flue 12 ...

Embodiment 2

[0025] On the basis of the above embodiments, in this embodiment, a heat medium water heater 6 capable of heat exchange with the primary air duct is arranged between the air blower and the steam heater 5, and the main flue 11 and the A flue gas waste heat recovery device 7 is arranged between the dust collectors, and the flue gas waste heat recovery device 7 communicates with the heat medium water heater 6 through a pipeline circulation, and the flue gas waste heat recovery device 7 communicates with the heat medium water heater 6 through a pipeline A circulating pump 9 and a regulating valve 10 are arranged on it.

[0026] The heat medium water heater 6, the flue gas waste heat recovery device 7, the water supply tank 8, the circulation pump 9 and the regulating valve 10 together form a closed cycle of flue gas waste heat recovery, and the flue gas in the air preheater 1 enters the flue gas after heat exchange In the gas waste heat recovery device 7, the heat medium water in ...

Embodiment 3

[0031] On the basis of the above embodiments, in this embodiment, the waste heat recovery system includes a high-pressure smoke-water heat exchanger 3 capable of heat exchange with the bypass flue 12, and the inlet of the high-pressure smoke-water heat exchanger 3 is connected with The feedwater pump 15 and the outlet of the high-pressure smoke-water heat exchanger 3 are connected with the boiler.

[0032] The feedwater pump 15 supplies water to the high-pressure flue-water heat exchanger 3. In the high-pressure flue-water heat exchanger 3, the water and the flue gas perform heat exchange, and the water after the heat exchange enters the economizer of the boiler to protect the bypass The heat of the flue gas in the flue 12 is recycled.

[0033] In this embodiment, the high-pressure smoke-water heat exchanger 3 is connected in parallel with a steam turbine water supply system 13 .

[0034] The outlet water of the feed water pump 15 is divided into two paths, one path enters th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com