A Control Calculation Method for the Propulsion System of Flexible Boom Tunneling Machine

A technology of propulsion system and calculation method, which is applied in the direction of earth drilling, mining equipment, tunnels, etc., can solve the problems of cumbersome process, less people, large errors, etc., and achieve the goal of improving control accuracy, high promotion value, and precise excavation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

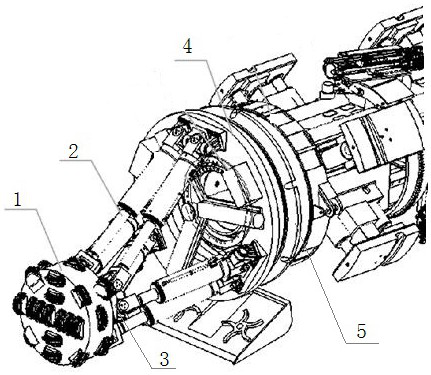

[0039] Example 1, such as figure 2 As shown, a control calculation method for the propulsion system of a flexible boom roadheader, the parallel cylinder arm includes a static platform 3 and a dynamic platform 4, when in the initial position, the static platform 3 and the dynamic platform 4 are arranged in parallel, and the center of the static platform 3 is in line with the The center of the moving platform 4 is located on the same straight line, the static platform 3 is rotationally connected with the main beam system through the main bearing 5, the moving platform 4 is connected with the static platform 3 through 6 parallel oil cylinders 2, and the static platform 3 is provided with a cutter head 1 . The position of the center of the cutter head 1 indicates the position of the cutter head.

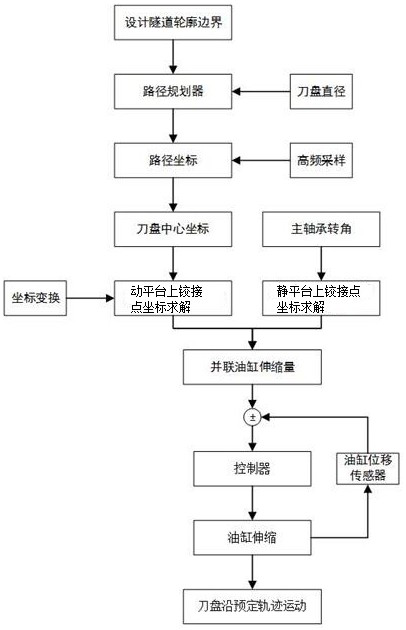

[0040] The calculation method for controlling the expansion and contraction of parallel cylinder arms includes the following steps: figure 1 as shown,

[0041] S1: According to the p...

Embodiment 2

[0045] Embodiment 2, a control calculation method for the propulsion system of a flexible boom roadheader, in step S3, the theoretical stretching amount S of the parallel oil cylinder arm cylinder is calculated i The steps are as follows:

[0046] S3.1 Measure the radius R of the static platform of the parallel cylinder arm and the initial rod length of the cylinder driver

[0047] S3.2 as Figure 4 As shown, let the static platform of the parallel oil cylinder arm follow the main bearing of the flexible arm roadheader to rotate at a certain moment θ, and the coordinates of the hinge point of the parallel oil cylinder arm cylinder on the static platform B θ (x 0 ,y 0 ,z 0 ) and the corresponding relationship between the rotation angle θ is: x 0 ,y 0 ,z 0 When the rotation angle of the static platform is θ, the coordinates of the hinge point of the parallel cylinder arm cylinder on the static platform;

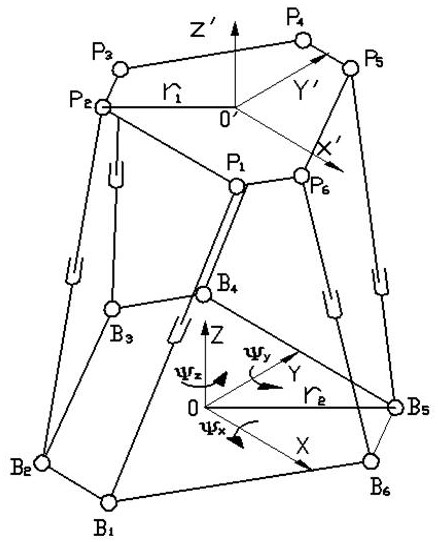

[0048] S3.3 as image 3 As shown, the static coordinate syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com