Foundation tamping device for fabricated building construction

A technology of building construction and compaction device, which is applied in construction, soil protection, infrastructure engineering and other directions, and can solve problems such as difficulty in adjusting strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

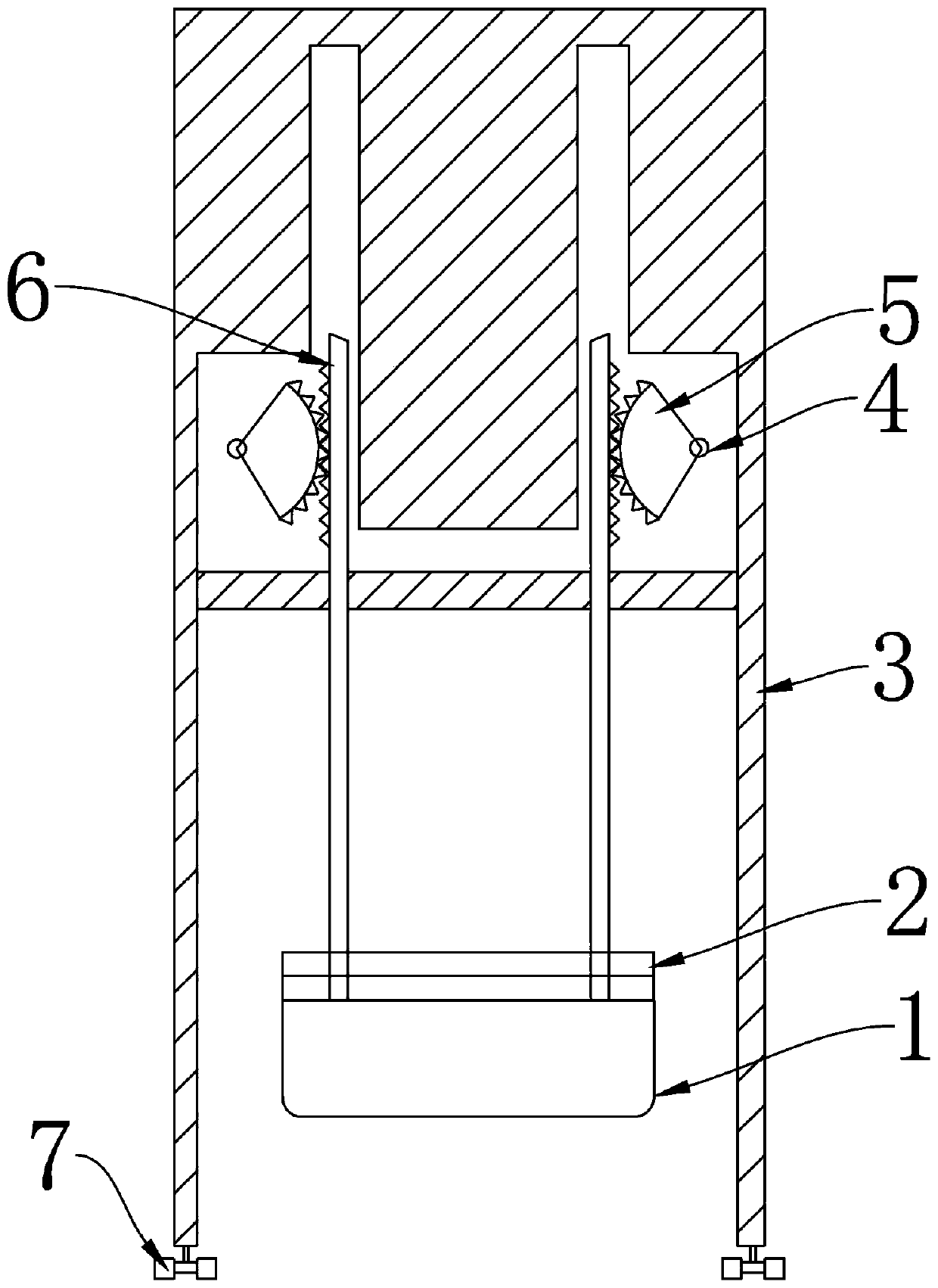

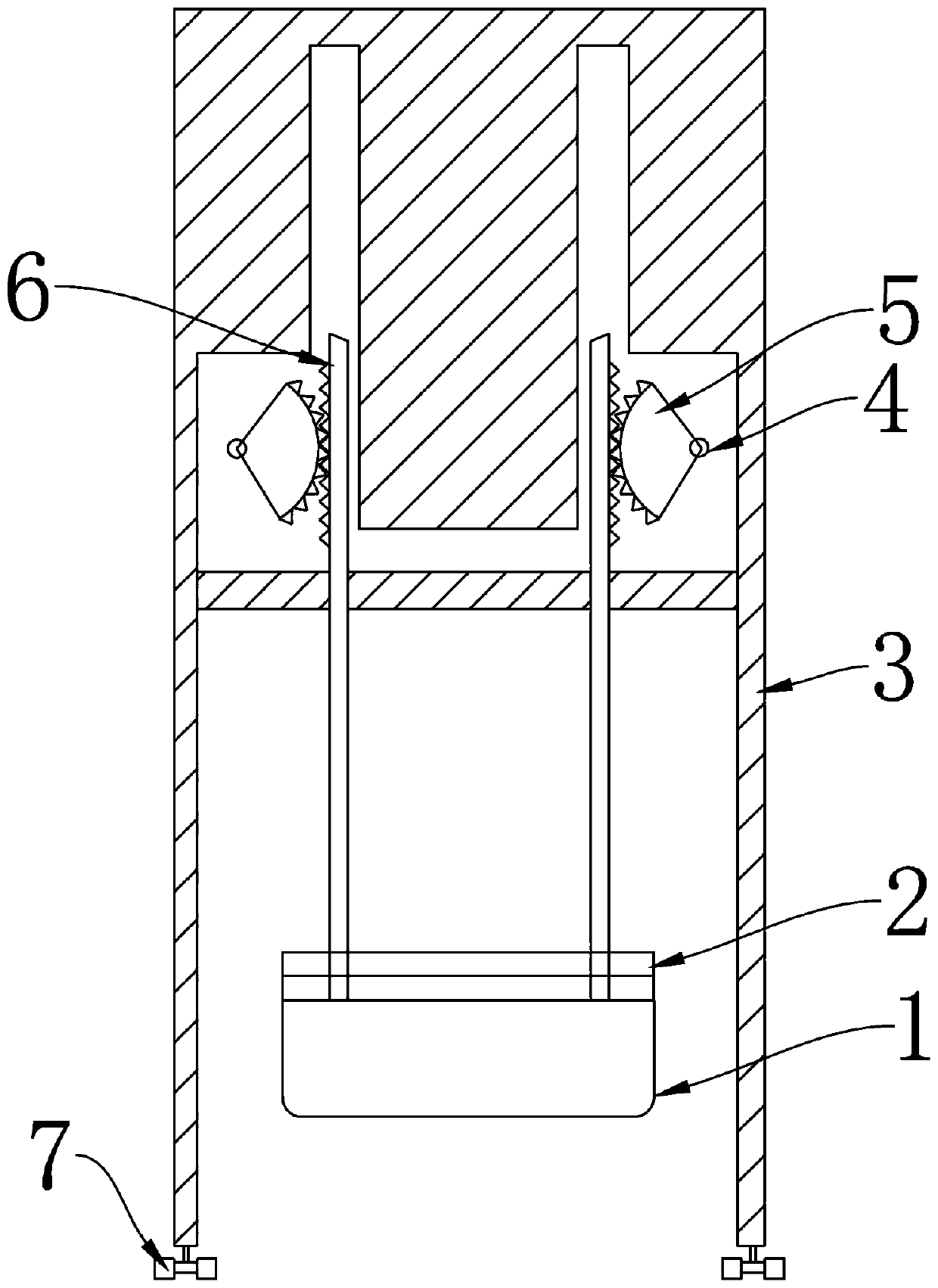

[0022] Such as figure 1 As shown, a ground compacting device for prefabricated building construction, which includes a hammer head 1, a casing 3, a sector gear 5, a rack bar 6, and a moving wheel 7, and the rack bar 6 meshes with the sector gear 5, There are two sets of rack bar 6 and fan-shaped teeth, which are placed inside the casing as a whole, and the fan-shaped gear is located on the upper part of the casing. Connect with the rotating shaft 4.

[0023] Said casing 3 is a square casing, and a reserved airtight space for accommodating the sector gear 5 is arranged inside, and the movement wheels are arranged at four corners of the casing, so as to facilitate the movement of the tamping device during use.

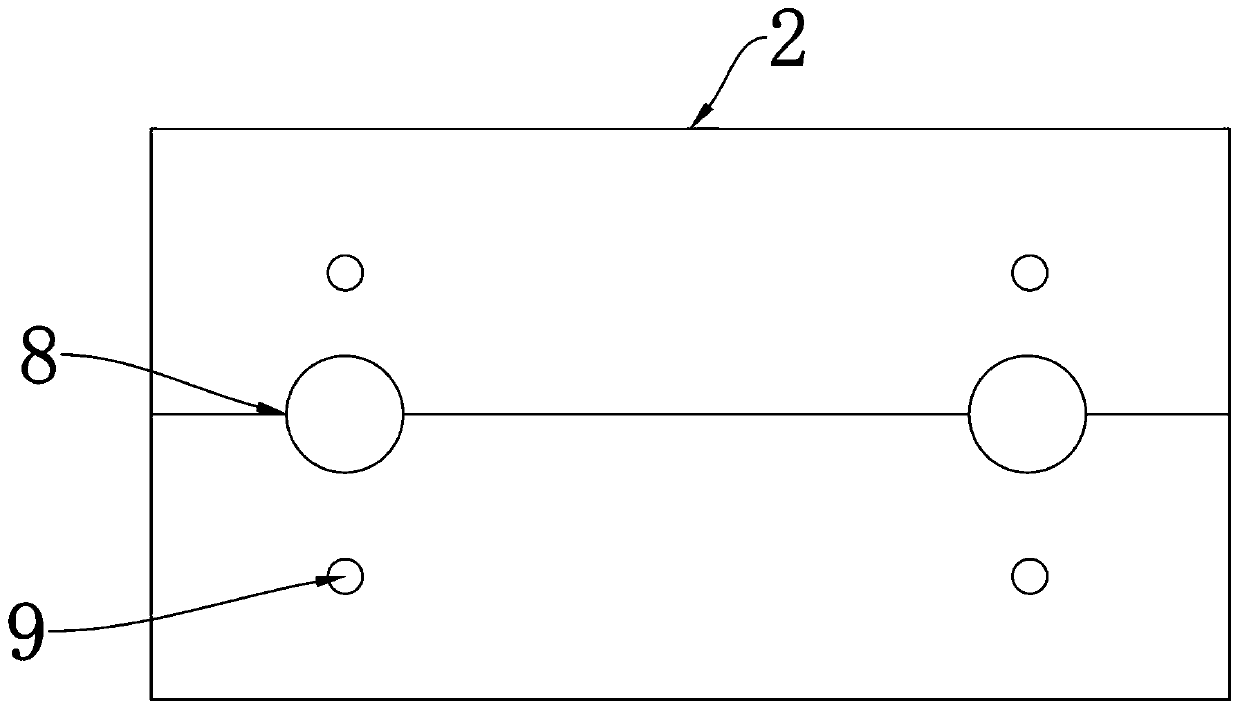

[0024] There is also an installation area for additional weight 2 on the upper part of the hammer head 1. The additional weight 2 is consistent with the shape of the upper part of the head. The additional weight is divided into two parts by the hole 8 of the rack bar. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com