Intelligent transshipping device after mobile crushing station and transshipping method thereof

A mobile crushing and intelligent technology, which is applied in the direction of transportation, packaging, conveyors, etc., can solve the problems of unsatisfactory blasting and shooting, and short length, so as to save transition reset time, save reset installation time, and reduce the initial installation site requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

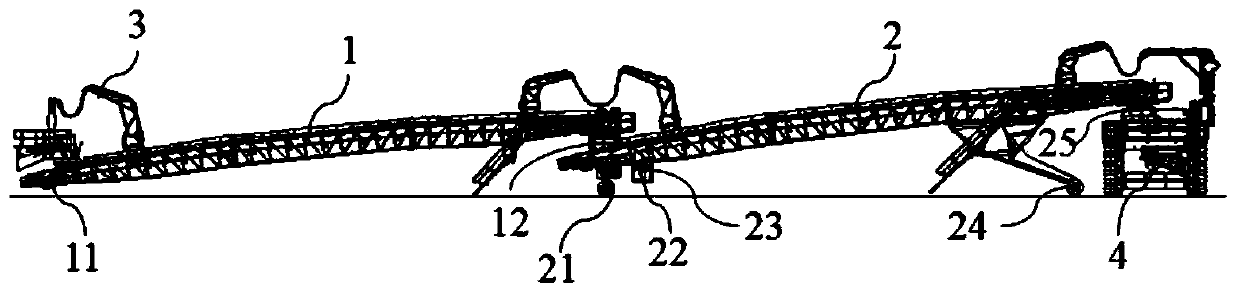

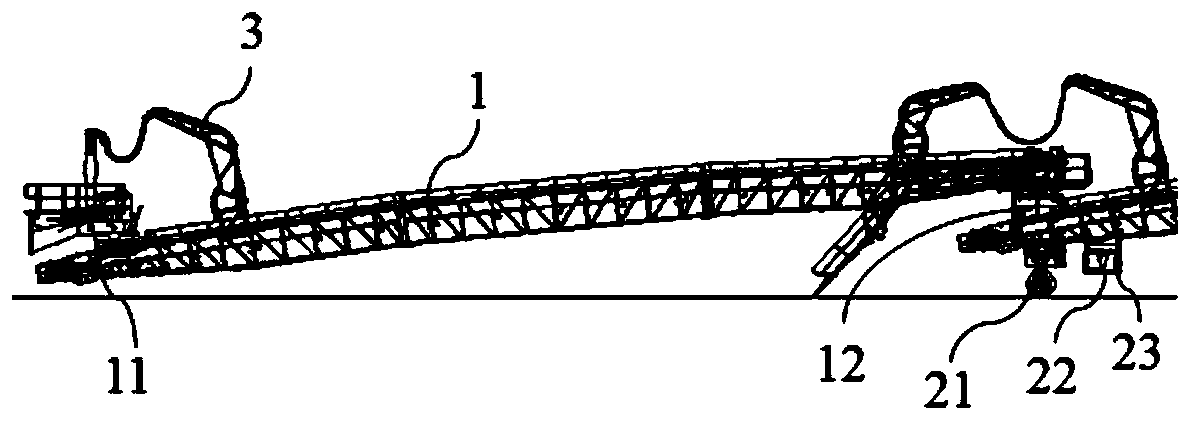

[0032] An intelligent reloading device behind a mobile crushing station in this embodiment, such as figure 1As shown, it includes the L1 conveyor 1, the L1 conveyor 1 is connected to the tail of the mobile crushing station through the connecting structure 11 provided at the head; the tail of the L1 conveyor 1 is connected to the L2 conveyor 2 through the turntable I12, and the The tail outlet of L1 conveyor 1 is set above the head of L2 conveyor 2 through turntable I12, L1 conveyor 1 can rotate around L2 conveyor 2 through turntable I12, and the angle between the two conveyors can reach 300°, thereby reducing Reprinted equipment installation site requirements for the first time; said L2 conveyor 2 under the head is provided with a steering support wheel set 21, the tail of the L2 conveyor 2 is provided with a lifting wheel set 24 below, through which the lifting wheel set 24 can The tail outlet of L2 conveyor 2 is lifted above the mobile discharge funnel 4, so as to ensure tha...

Embodiment 2

[0034] An intelligent reloading device behind a mobile crushing station in this embodiment, the basic structure is the same as that of Embodiment 1, the differences and improvements are as follows: figure 2 As shown, the turntable I12 is a hollow cylindrical structure, so that after the gravel passes through the discharge port at the tail of the L1 conveyor 1, it is discharged into the feed port above the head of the L2 conveyor 2 to realize the reloading and transportation of the gravel; Turntable I is adaptively connected above the feed inlet of L2 conveyor 2 head, and L1 conveyor can rotate around L2 conveyor to reduce site requirements.

Embodiment 3

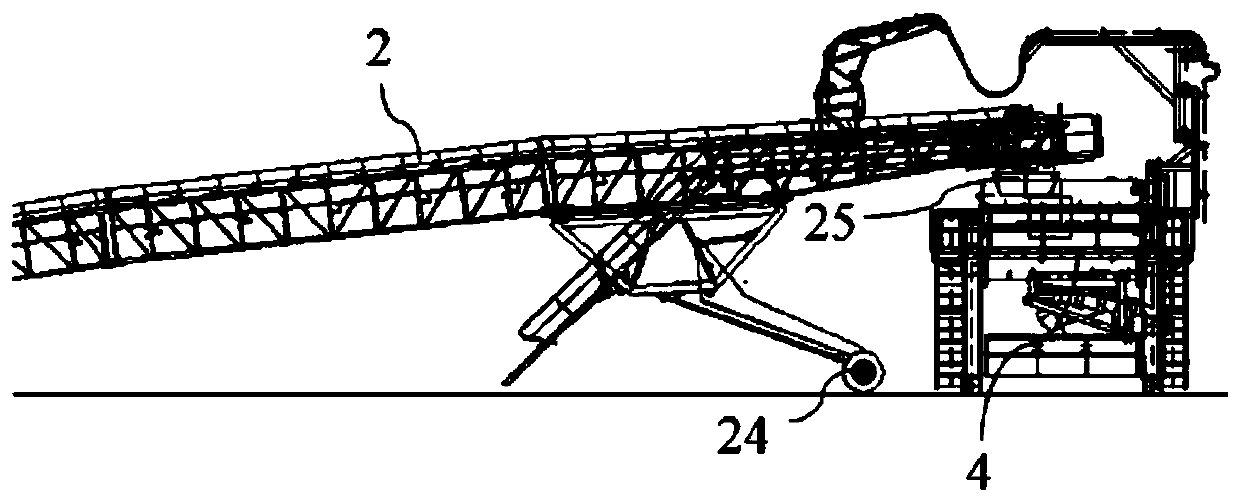

[0036] An intelligent reloading device behind a mobile crushing station in this embodiment, the basic structure is the same as that of Embodiment 2, the differences and improvements are as follows: image 3 As shown, the tail of the L2 conveyor 2 is also provided with a turntable II 25, the turntable II 25 is a hollow cylindrical structure, and can be flexibly connected above the feed port of the mobile unloading funnel 4; when the reloading device moves , the turntable II 25 is in contact with the feed port of the mobile discharge funnel 4, so that the L2 conveyor 2 can rotate around the mobile discharge funnel 4, so that when the reloading device is moved, the L1 conveyor 1 and the L2 conveyor 2 do not need to be separated; when When the reloading device is working, the L2 conveyor 2 can discharge the crushed stones from its discharge port through the turntable II 25 into the inside of the feed port of the mobile discharge funnel 4, so as to realize long-distance reloading an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com