Manual stamping device

A seal and sliding rod technology, applied in printing, stamping, etc., can solve structural defects, reduce stamping efficiency, troublesome ink filling and other problems, and achieve the effect of avoiding troubles in use and reducing stamping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below in conjunction with the drawings and specific embodiments. It should be noted that in the drawings or descriptions, similar or identical parts use the same figure numbers, and implementations that are not shown or described in the drawings The method is a form known to those of ordinary skill in the art. In addition, the directional terms mentioned in the embodiments, such as "upper", "lower", "top", "bottom", "left", "right", "front", "rear", etc., are only for reference to the accompanying drawings. The directions are not intended to limit the protection scope of the present invention.

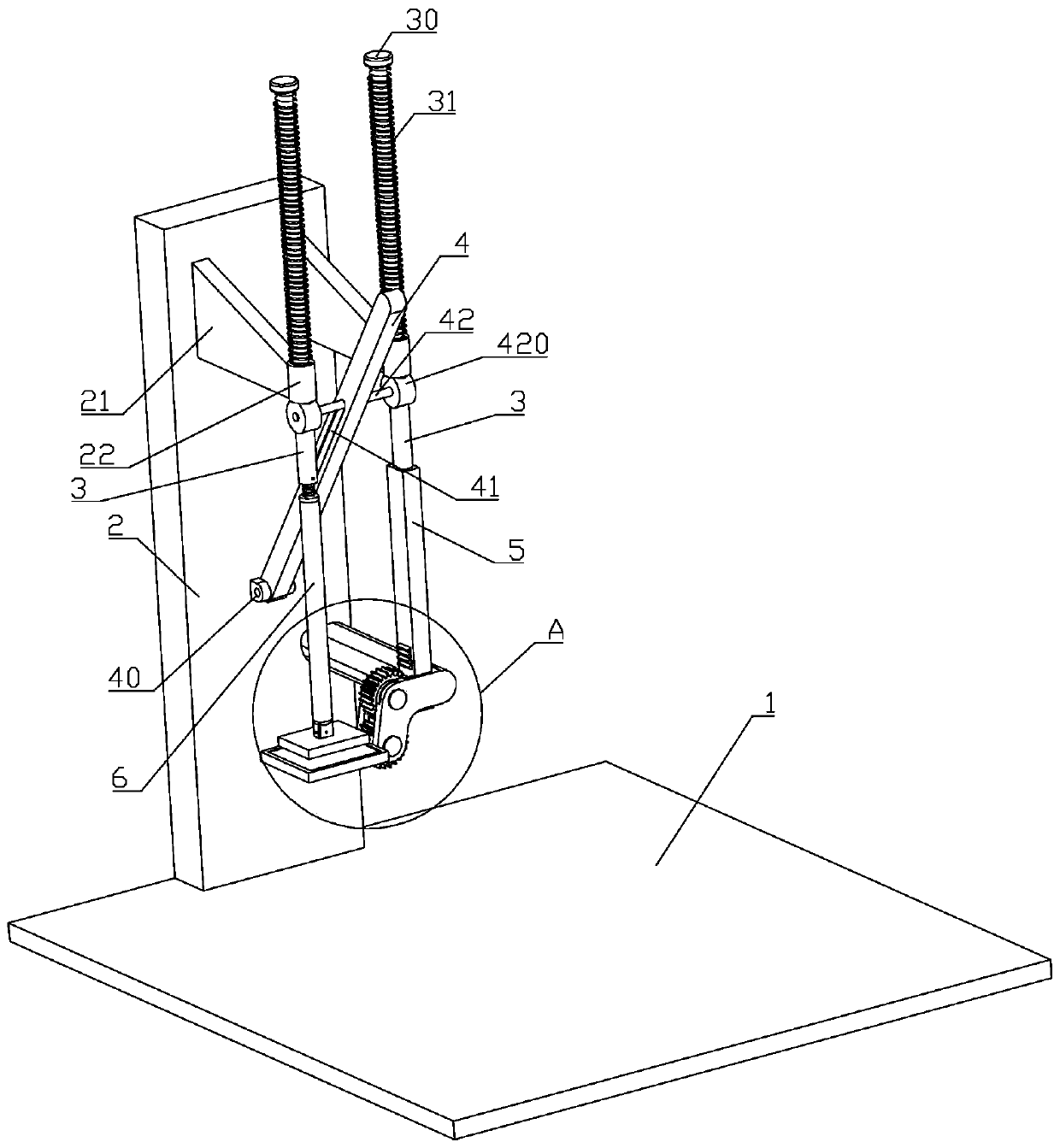

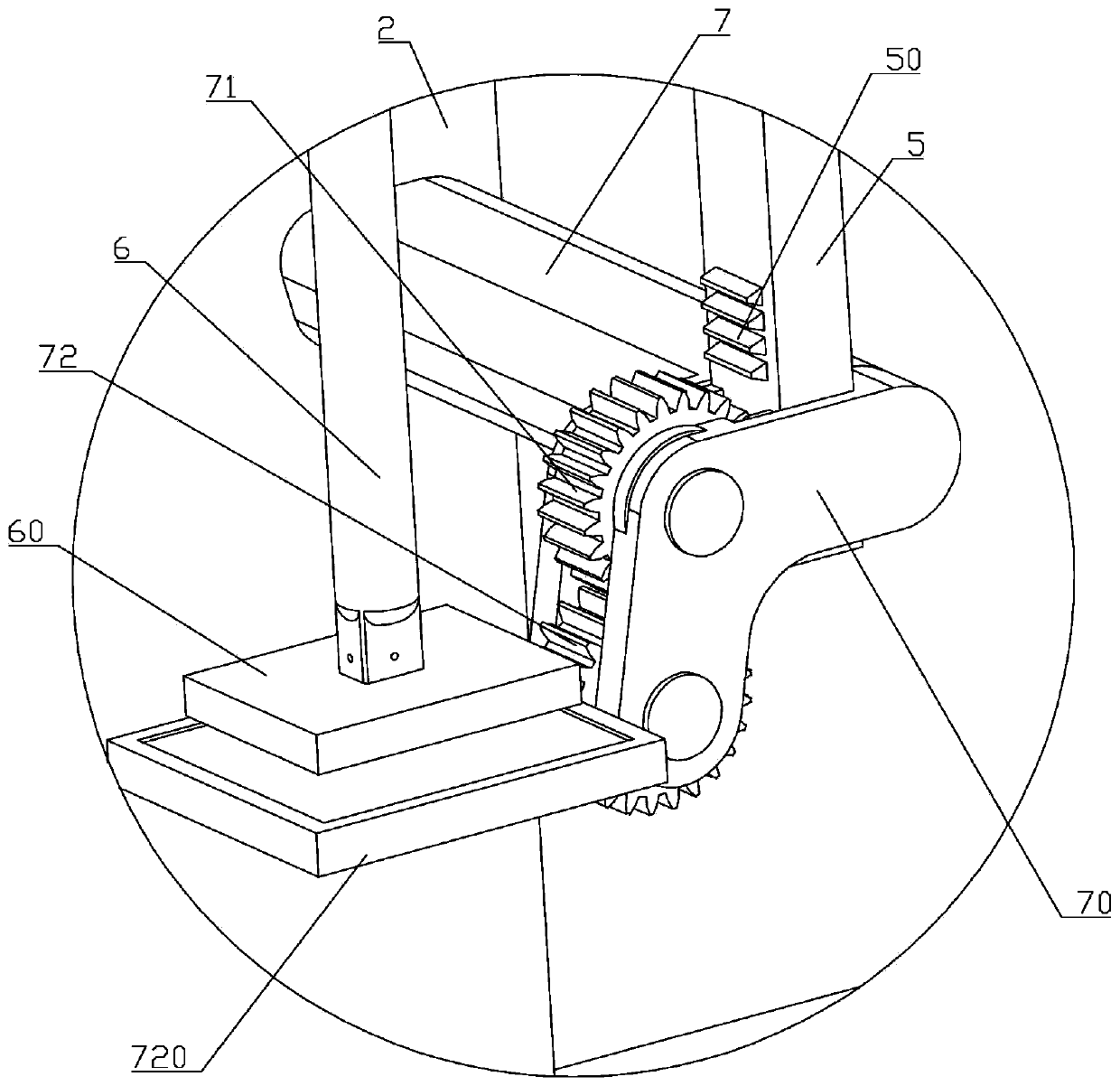

[0043] like Figure 1 to Figure 14As shown, a manual stamping device of the present invention includes a base 1, a vertical plate 2 is fixedly installed on the base 1, two supporting plates 21 are installed horizontally on the upper part of the vertical plate 2, and a sleeve is fixedly installed on the free end of the supporting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com