A corner guard plate processing equipment

A technology for processing equipment and corners, which is applied in the field of corner guard plate processing equipment, can solve problems such as hidden safety hazards, time-consuming and labor-intensive work efficiency, and achieve the effects of improved production efficiency, improved effects, and safe production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

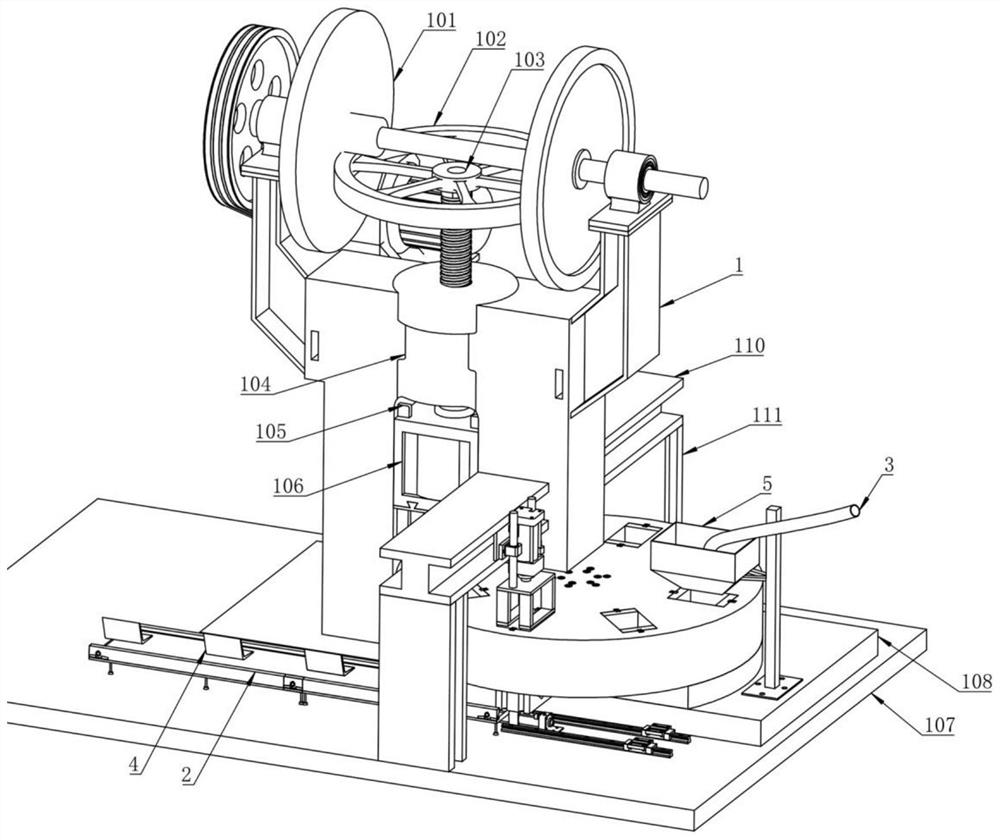

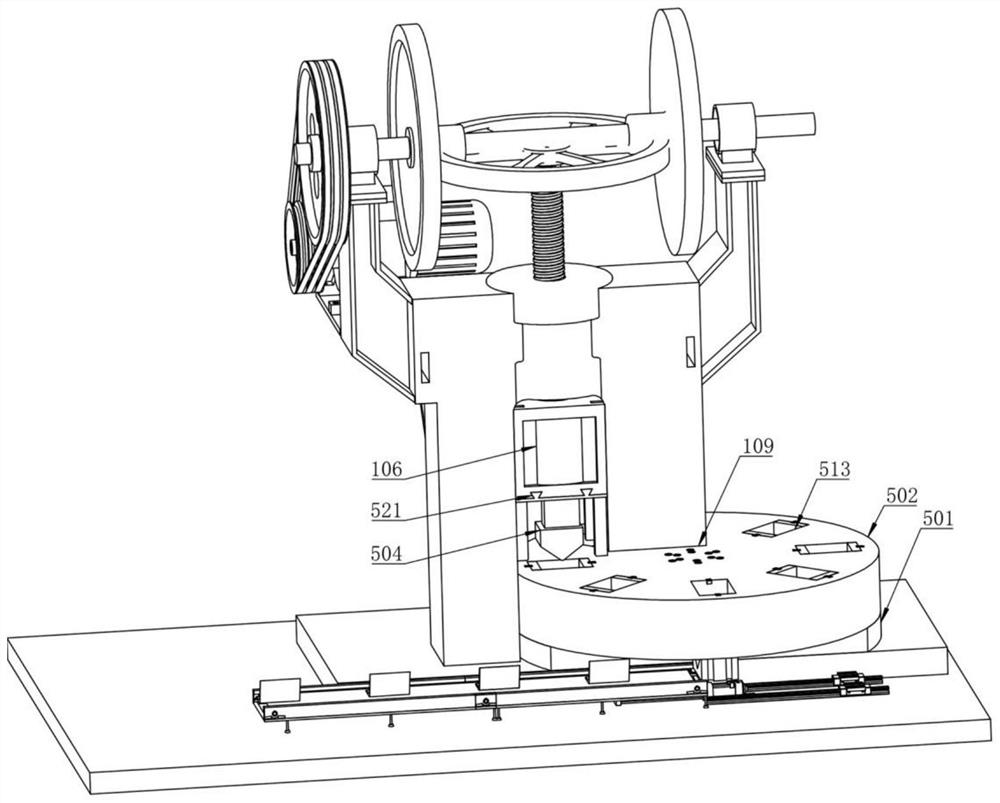

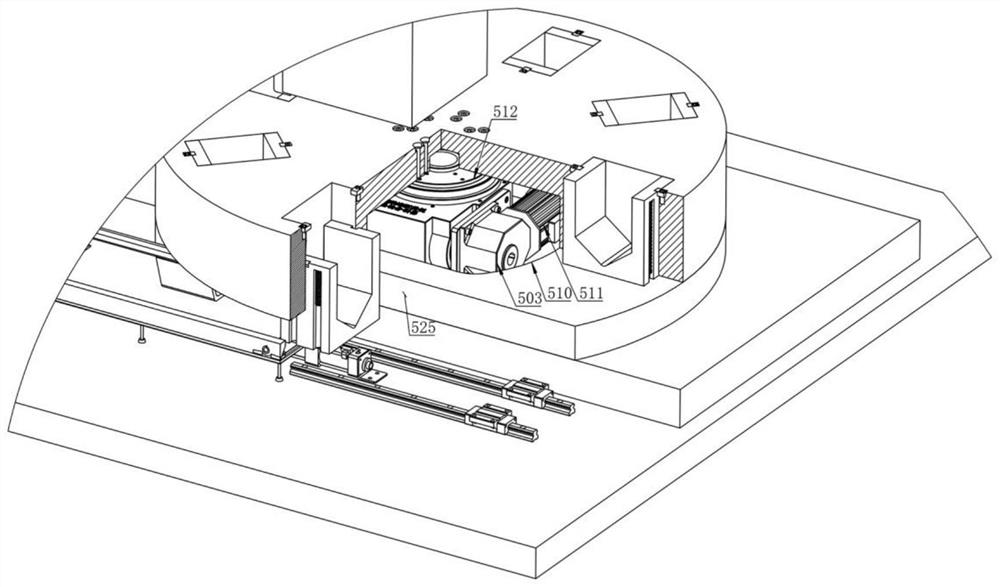

[0033] Specific implementation mode one: combine Figure 1-8As shown, a corner guard plate processing equipment is characterized in that it includes a friction press 1, a conveyor belt 2, a feeding pipe 3, a finished corner guard plate 4, and an automatic rotary die device 5; the top of the friction press 1 is set There are two driving discs 101; a friction disc 102 is arranged between the two driving discs 101; a screw rod 103 is arranged below the friction disc 102; a fixing seat 104 is arranged at the middle position of the top of the friction press 1; the screw rod 103 is threaded through and connected to the middle part of the fixed seat 104; both sides of the friction press 1 are provided with guide rails 105 in the vertical direction; the bottom of the screw rod 103 is fixedly provided with a briquetting block 106; On the guide rail 105; the bottom of the friction press 1 is provided with a platform 107; the top of the platform 107 is provided with a fixed platform 108;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com