Liftable welding turntable

A lifting type and turntable technology, which is applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of affecting welding efficiency, the inability to quickly and conveniently weld the weld seam of the workpiece, and the inability of the welding turntable to adjust the position of the workpiece And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be further described below in conjunction with the drawings and embodiments. The following embodiments are only used to explain the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

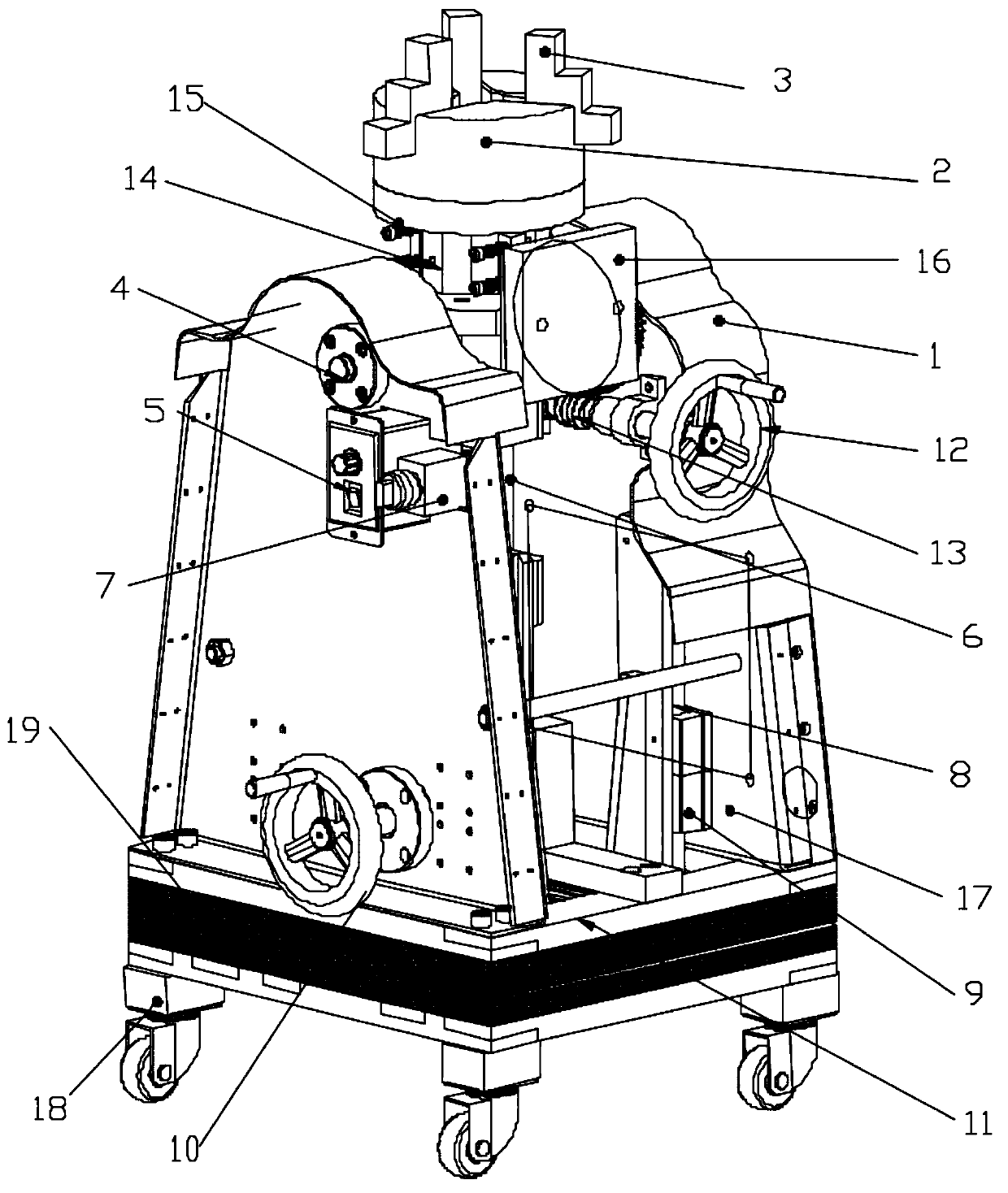

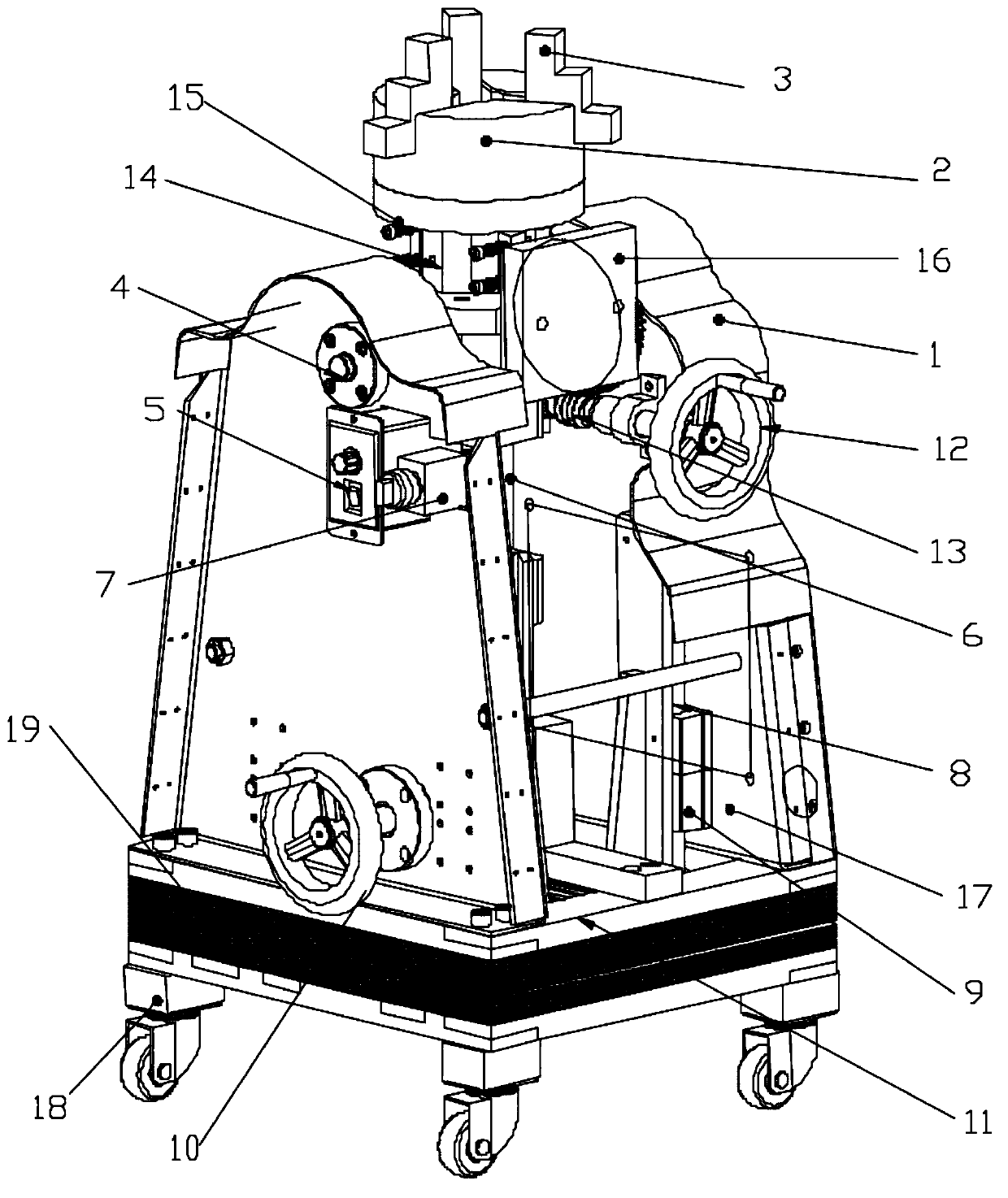

[0020] Such as figure 1 As shown, the present invention is a liftable welding turntable, which includes a housing 1, a chuck 2, a connecting shaft, a clamping jaw 3, an angle adjustment mechanism, a rotating shaft 4, a speed controller 5, a rotating motor 6, a switch 7, a lifting The mechanism 8, the lifting bearing 9, the hand wheel 10 and the base 11, the clamping jaw 3 is set on the chuck 2 for fixing the workpiece, one end of the connecting shaft is connected to the chuck 2, and the end of the connecting shaft away from the chuck 2 is connected to the rotating motor 6 is connected. When working, the rotating motor 6 drives the chuck 2 to rotate for we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com