Convenient hardware grinding and cutting residual powder collecting hopper

A collection bucket, a portable technology, applied in the field of portable metal grinding and cutting waste powder collection bucket, can solve the problems of arm pain, inconvenience of powder collection, and increase the time of powder collection, so as to prevent arm pain and loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

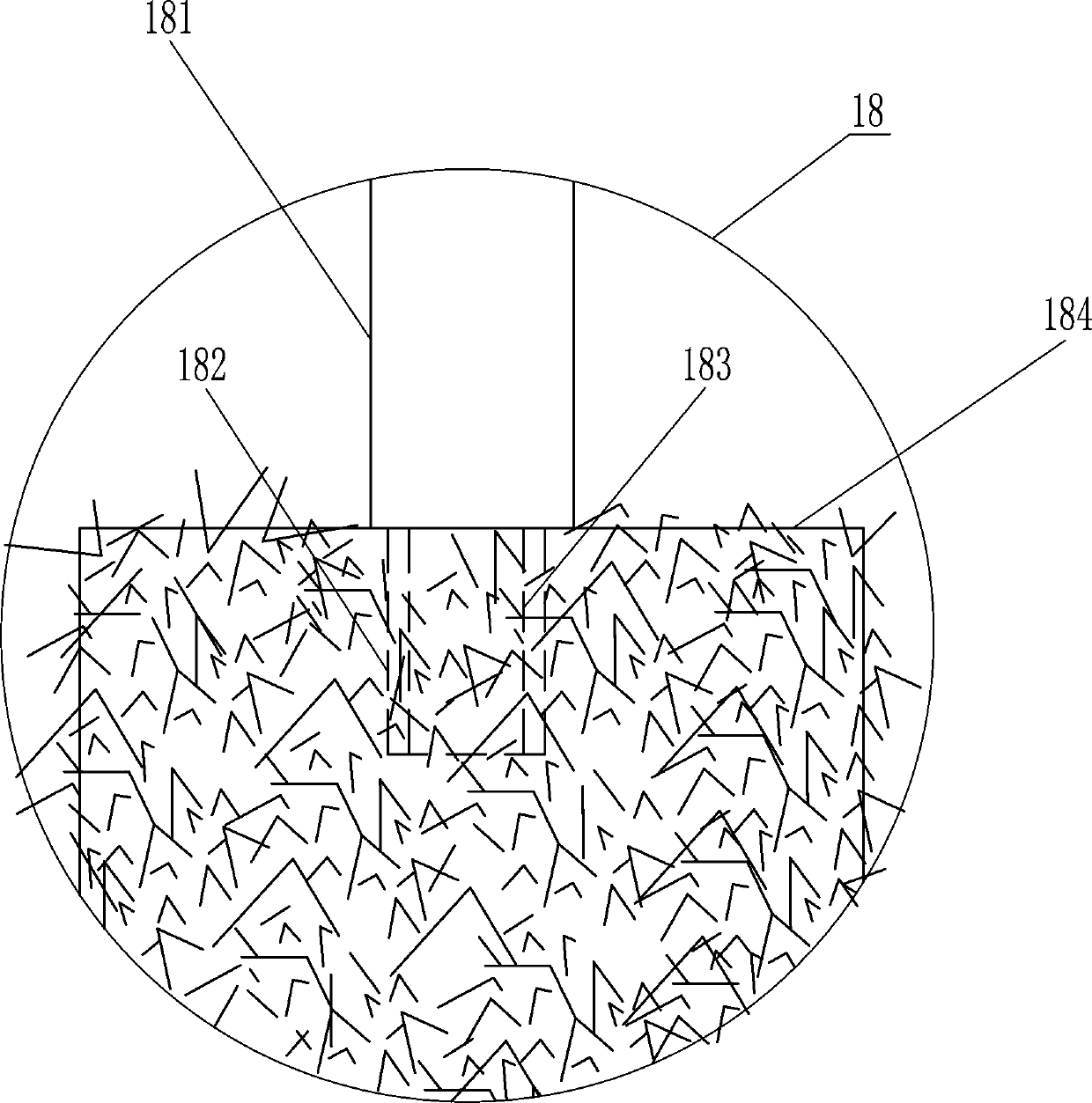

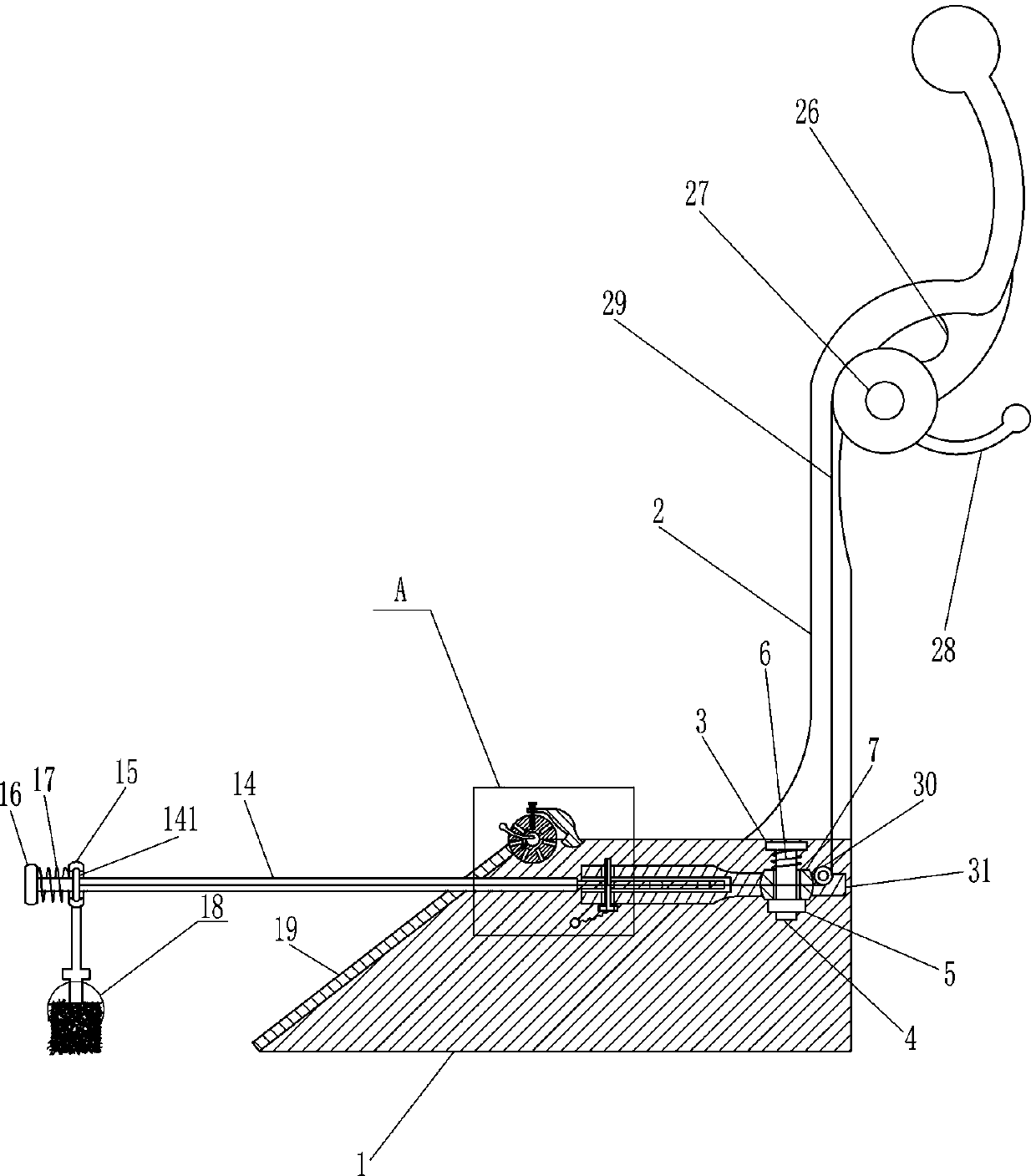

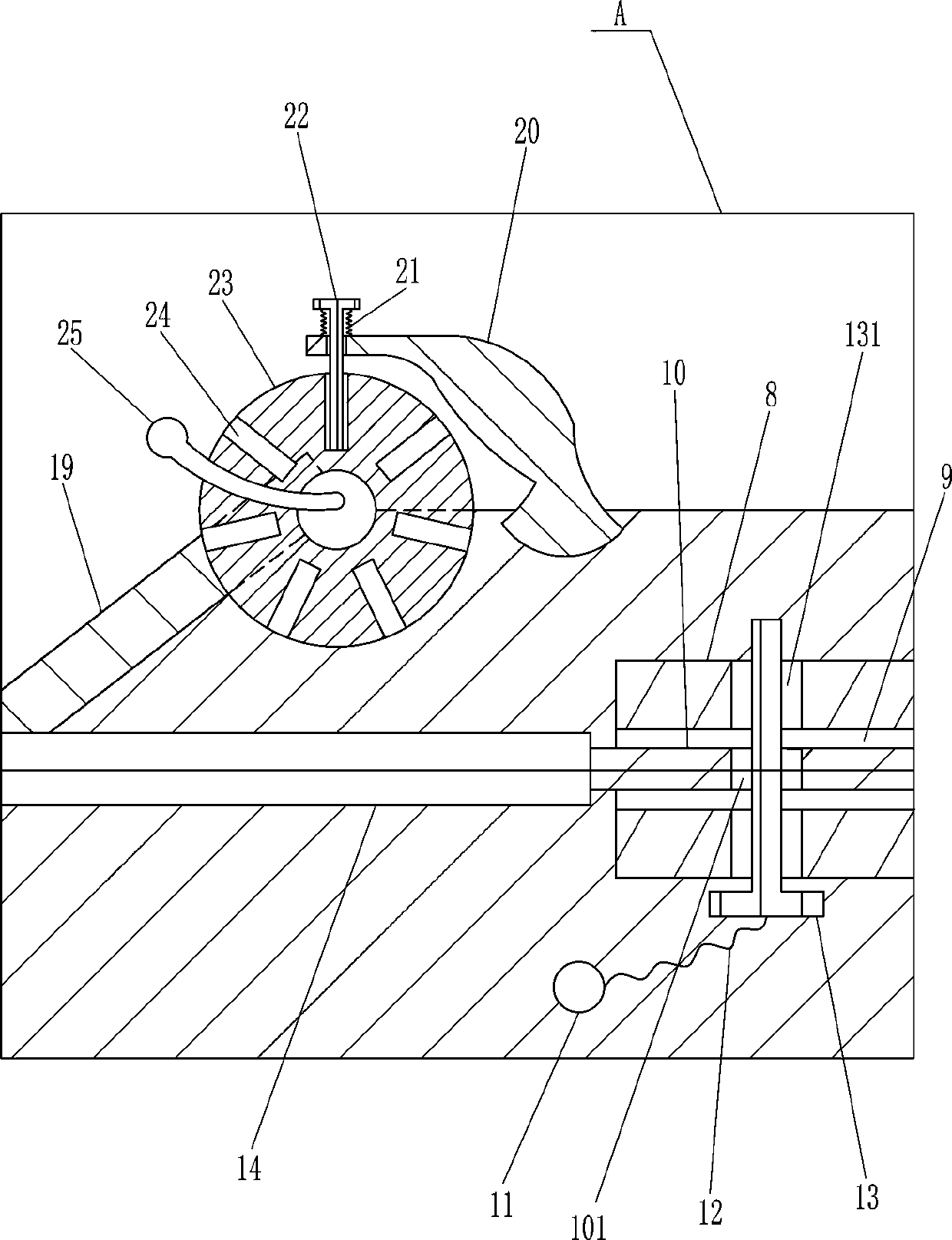

[0016] A convenient metal grinding and cutting powder collection bucket, such as Figure 1-3 As shown, it includes a collecting bucket body 1, a handle 2, a connecting block 3, a first screw rod 4, a nut 5, a first spring 6, a lifting block 7, a first mounting column 8, a first insertion rod 10, and a second screw rod 13. Straight slide rail 14, first pole 141, sliding sleeve 15, block 16, second spring 17 and dismounting mechanism 18, the right side of the top of the collection bucket body 1 is fixed with a handle 2, and the collection bucket body 1 passes through the bolt The way of connection is connected with the handle 2, the upper part of the front side of the collection bucket body 1 is fixed with a connecting block 3, the bottom of the connecting block 3 is provided with a first screw 4, and the first screw 4 is slidably provided with a first mounting column. 8 The lifting block 7 that moves up and down, the first screw rod 4 is provided with a nut 5 that can move the ...

Embodiment 2

[0018] A convenient metal grinding and cutting powder collection bucket, such as Figure 1-3 As shown, it includes a collecting bucket body 1, a handle 2, a connecting block 3, a first screw rod 4, a nut 5, a first spring 6, a lifting block 7, a first mounting column 8, a first insertion rod 10, and a second screw rod 13. Straight slide rail 14, first pole 141, sliding sleeve 15, block 16, second spring 17 and dismounting mechanism 18, the right side of collecting bucket body 1 top is fixed with handle 2, the front of collecting bucket body 1 The upper part of the side is fixed with a connecting block 3, the bottom of the connecting block 3 is provided with a first screw 4, the first screw 4 is slidably provided with a lifting block 7 that can move the first mounting column 8 up and down, and the first screw 4 is provided with The nut 5 that can make the lifting block 7 move up and down, the first spring 6 is wound on the first screw rod 4, the top of the first spring 6 is aff...

Embodiment 3

[0021] A convenient metal grinding and cutting powder collection bucket, such as Figure 1-3As shown, it includes a collecting bucket body 1, a handle 2, a connecting block 3, a first screw rod 4, a nut 5, a first spring 6, a lifting block 7, a first mounting column 8, a first insertion rod 10, and a second screw rod 13. Straight slide rail 14, first pole 141, sliding sleeve 15, block 16, second spring 17 and dismounting mechanism 18, the right side of collecting bucket body 1 top is fixed with handle 2, the front of collecting bucket body 1 The upper part of the side is fixed with a connecting block 3, the bottom of the connecting block 3 is provided with a first screw 4, the first screw 4 is slidably provided with a lifting block 7 that can move the first mounting column 8 up and down, and the first screw 4 is provided with The nut 5 that can make the lifting block 7 move up and down, the first spring 6 is wound on the first screw rod 4, the top of the first spring 6 is affi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com