Molten salt impurity removal method suitable for chemical tempering production and method for improving glass strength

A technology of chemical tempering and molten salt, which is applied in the purification of alkali metal nitrate, etc., and can solve problems such as unsatisfactory results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

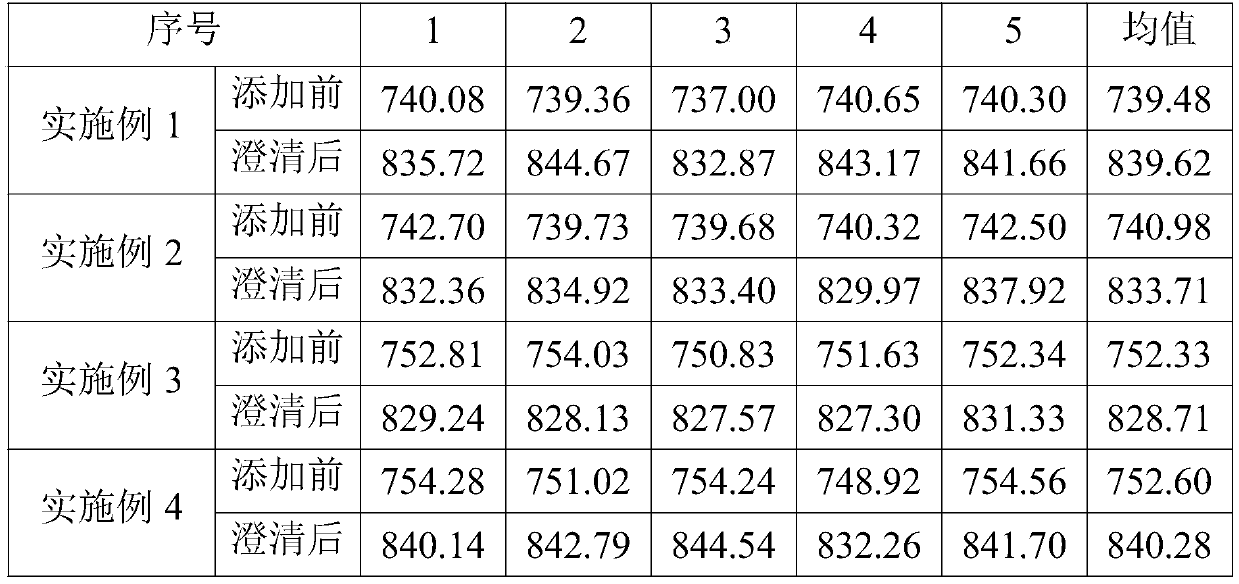

Examples

Embodiment 1

[0046] A method for improving the strength of glass by chemical tempering, comprising the following steps:

[0047] Step 1) Use a stress tester to measure and record the stress value of each batch of tempered glass, if it is less than 770MPa, stop the tempering operation.

[0048] Step 2) adding 0.5% KOH to the mass percentage of the molten salt to adjust the pH value of the molten salt to 9.

[0049] Step 3) adding 0.5% potassium carbonate and 0.5% potassium phosphate accounting for the mass percentage of the molten salt, and fully stirring at the same time.

[0050] Step 4) adding 0.5% potassium pyroantimonate solution accounting for the mass percentage of the molten salt, and fully stirring at the same time.

[0051] Step 5) adding 1% silicic acid to the mass percentage of the molten salt to adjust the pH value of the molten salt to 7.

[0052] Step 6) Adding 0.5% aluminum oxide based on the mass percentage of the molten salt.

[0053] Step 7) Clarify for 4h.

[0054] S...

Embodiment 2

[0056] A method for improving the strength of glass by chemical tempering, comprising the following steps:

[0057] Step 1) Use a stress tester to measure and record the stress value of each furnace of tempered glass, if it is less than 770MPa, stop the tempering operation.

[0058] Step 2) adding 0.1% KOH to the mass percentage of the molten salt to adjust the pH value of the molten salt to 9.

[0059] Step 3) adding 0.5% potassium carbonate and 0.5% potassium phosphate accounting for the mass percentage of the molten salt, and fully stirring at the same time.

[0060] Step 4) adding 0.5% potassium pyroantimonate to the mass percentage of the molten salt, and fully stirring at the same time.

[0061] Step 5) adding 2% silicic acid to the mass percentage of the molten salt to adjust the pH value of the molten salt to 7.

[0062] Step 6) Adding 0.5% aluminum oxide based on the mass percentage of the molten salt.

[0063] Step 7) Clarify for 4h.

[0064] Step 8) Tempering op...

Embodiment 3

[0066] A method for improving the strength of glass by chemical tempering, comprising the following steps:

[0067] Step 1) Use a stress tester to measure and record the stress value of each batch of tempered glass, if it is less than 770MPa, stop the tempering operation.

[0068] Step 2) adding 0.5% KOH to the mass percentage of the molten salt to adjust the pH value of the molten salt to 13.

[0069] Step 3) adding 1% potassium carbonate and 1% potassium phosphate accounting for the mass percentage of the molten salt, while fully stirring.

[0070] Step 4) adding 0.5% potassium pyroantimonate to the mass percentage of the molten salt, and fully stirring at the same time.

[0071] Step 5) adding 1% silicic acid to the mass percentage of the molten salt to adjust the pH value of the molten salt to 7.

[0072] Step 6) Adding 0.5% aluminum oxide based on the mass percentage of the molten salt.

[0073] Step 7) Clarify for 4h.

[0074] Step 8) Tempering operation, using a str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com