An automatic unloader for hot melt adhesive film production

A hot-melt adhesive film and automatic unloading technology, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of labor cost, time consumption, and low work efficiency, so as to achieve high work efficiency and avoid sagging deformation , to avoid the effect of moving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

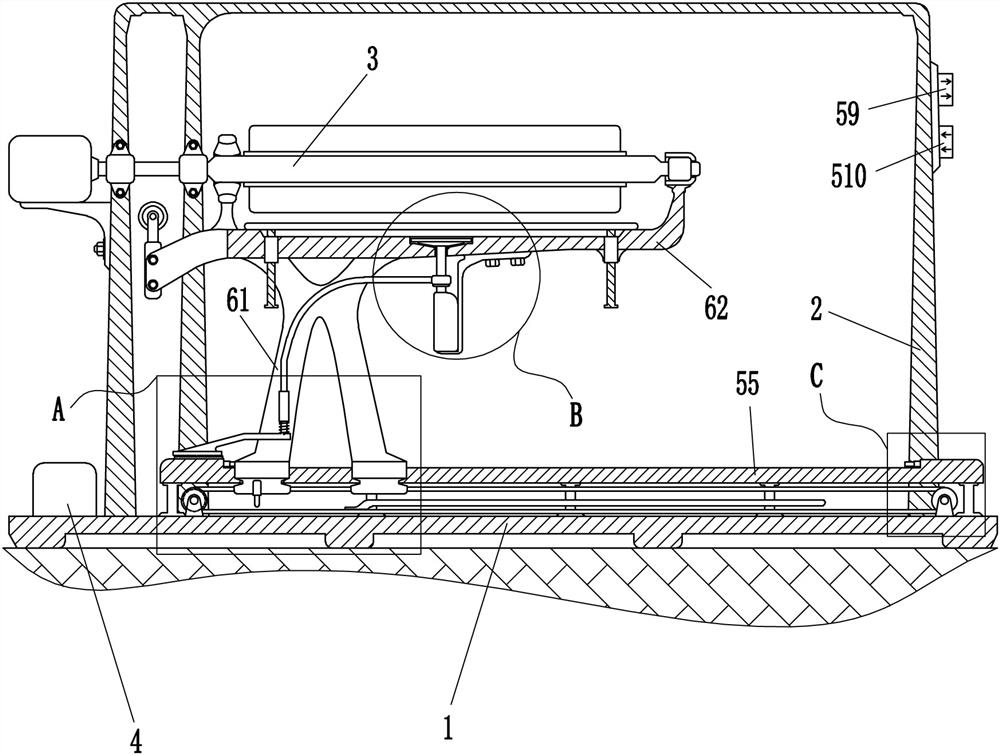

[0029] An automatic unloading machine for hot melt adhesive film production, such as Figure 1-6 As shown, it includes a base 1, a frame 2, a moving mechanism 5 and a push-out mechanism 6. A frame 2 and a moving mechanism 5 are installed on the top of the base 1. The frame 2 is located at the rear side of the moving mechanism 5, and the moving mechanism 5 is provided with a pushing Mechanism 6, the push-out mechanism 6 is used to push out the rolled hot-melt adhesive film, and the moving mechanism 5 is used to drive the push-out mechanism 6 to move laterally.

[0030] It also includes a control module, and the moving mechanism 5 and the control module are electrically connected.

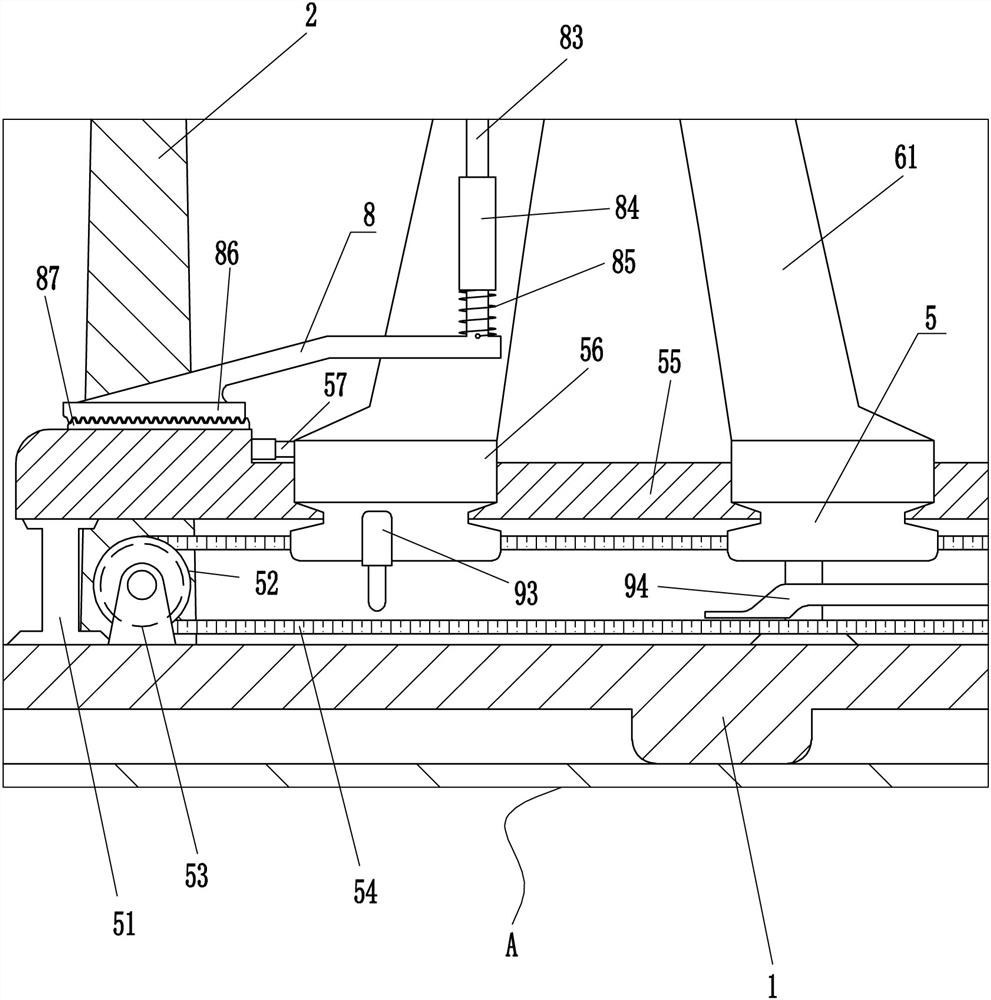

[0031] The moving mechanism 5 includes a pillar 51, a drum 52, a servo motor 53, a synchronous belt 54, a slide rail 55, a slider 56, a first travel switch 57, a second travel switch 58, a right shift key 59 and a left shift key 510, and a base 1 The top is fixedly connected with a servo motor 53 an...

Embodiment 2

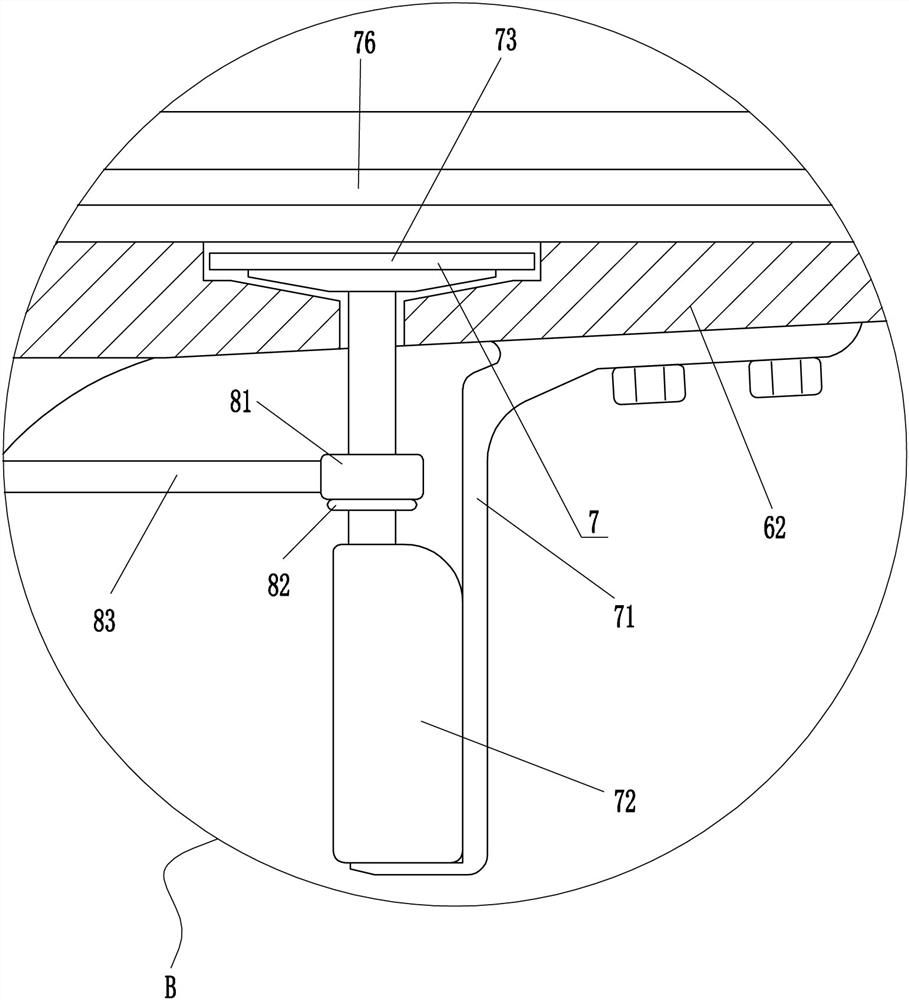

[0037] On the basis of Example 1, such as figure 2 , image 3 , Figure 4 , Image 6 , Figure 7 with Figure 8 As shown, a support mechanism 7 is also included, and the support mechanism 7 includes a mounting base 71, a first electric push rod 72, a pressure sensor 73, a guide sleeve 74, a guide rod 75 and a push plate 76, and the middle of the bottom of the horizontal plate 62 passes through Mounting seat 71 is equipped with first electric push rod 72, and first electric push rod 72 passes through cross plate 62, and pressure sensor 73 is installed on the telescoping rod top of first electric push rod 72, and cross plate 62 left and right parts are all embedded The guide sleeve 74 is installed in the guide sleeve 74, and the sliding type is provided with a guide rod 75 in the guide sleeve 74, and the top of the guide rod 75 is affixed with a push plate 76.

[0038] Also include positioning mechanism 8, positioning mechanism 8 includes slip ring 81, baffle plate 82, con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com