Packing box for transportation and loading and unloading method

A packaging box and box body technology, applied in the field of packaging boxes, can solve problems such as laborious and troublesome, and achieve good protection and fast box packaging equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

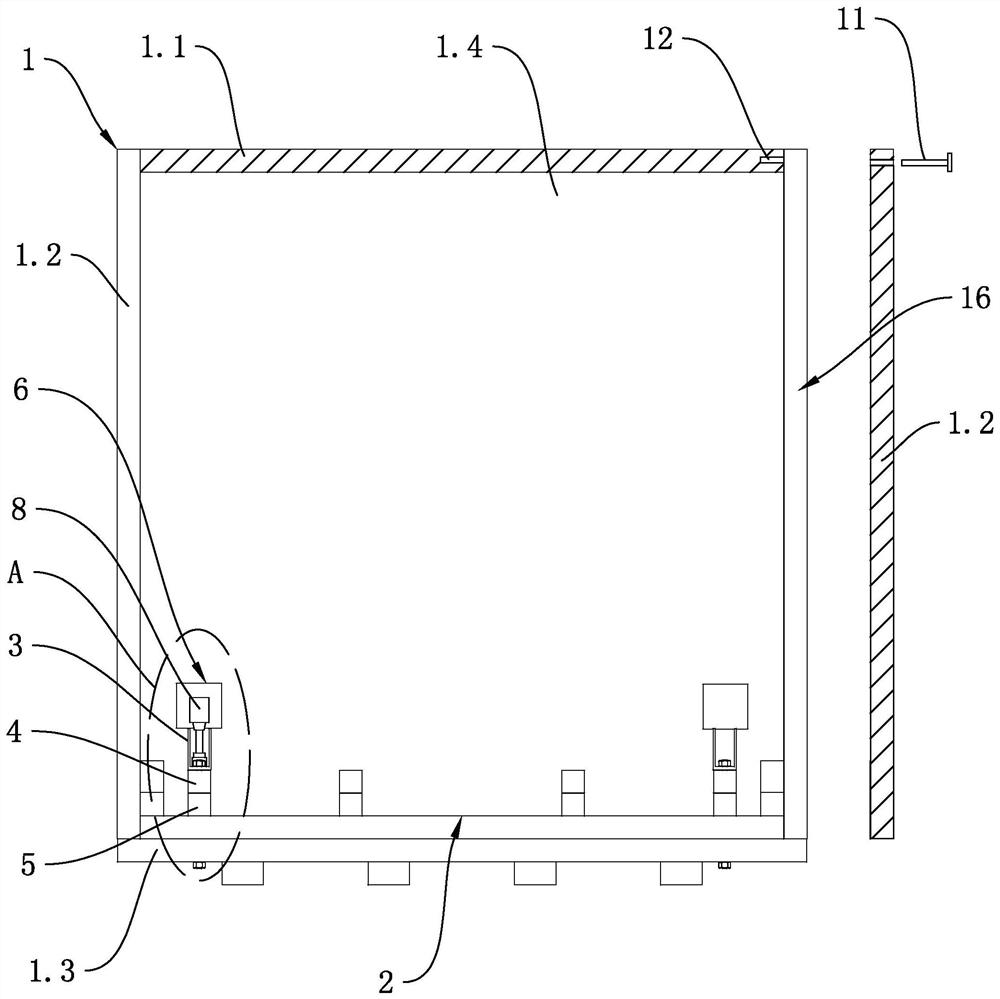

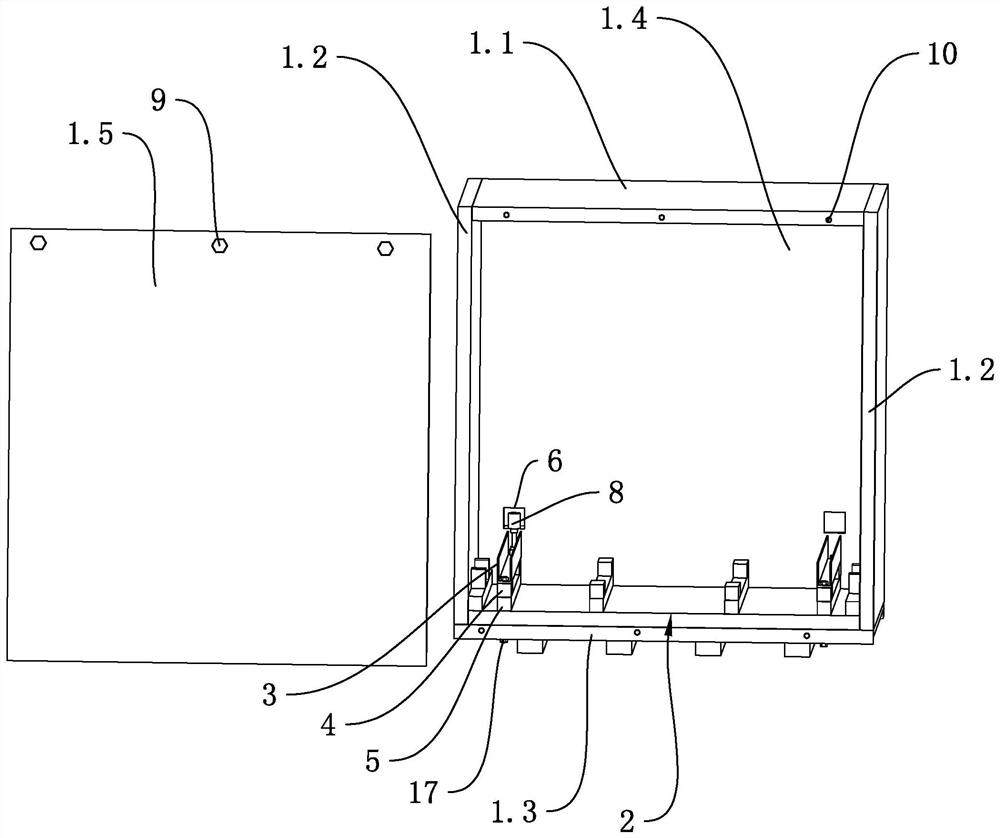

[0040] Embodiment 1: a kind of packaging case for transportation, with reference to figure 1 and image 3 , including a first box body 1 in the shape of a cuboid, the first box body 1 includes a bottom plate 1.3, a top plate 1.1, a front panel 1.5, a rear panel 1.4 and two side panels 1.2, a bottom plate 1.3, a top plate 1.1, a front panel 1.5, and a rear panel 1.4 and the two side panels 1.2 are rectangular plate structures, and together form a completed rectangular box.

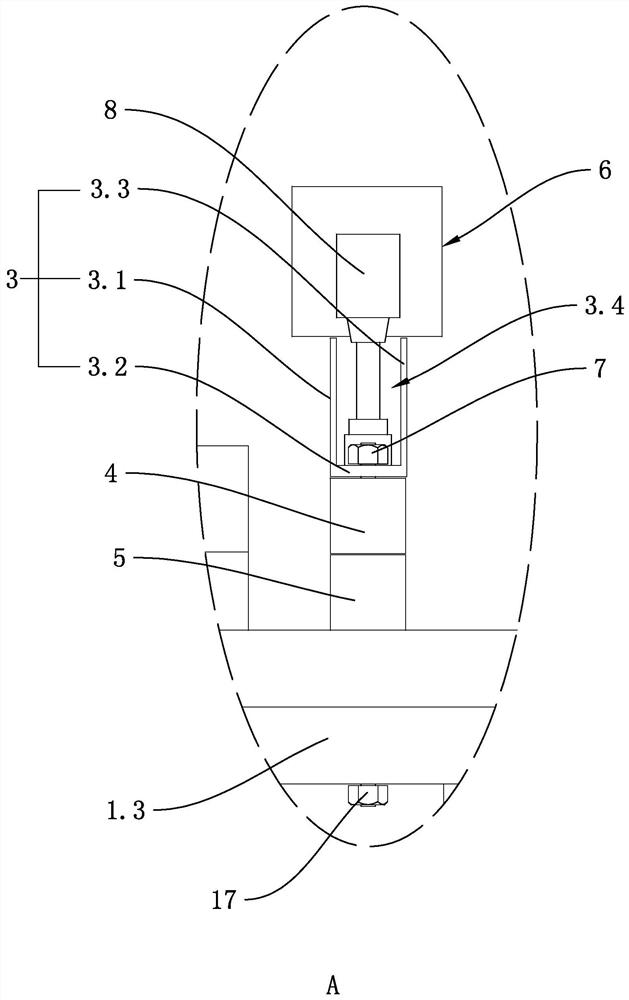

[0041] refer to figure 1 and figure 2 , the surface of the bottom plate 1.3 is fixedly provided with sliding wood 5, the number of sliding wood 5 is four, arranged and distributed along the length direction of the bottom plate 1.3, the sliding wood 5 located at the two ends of the bottom plate 1.3 is fixedly provided with pads 4, and the shape of the pads 4 is The cuboid is distributed on the two ends of the sliding wood 5, and the pressure bar 3 is fixedly arranged on the surface of the cushion block 4...

Embodiment 2

[0050] Embodiment 2: A method for loading and unloading equipment in a packaging box, using the packaging box described in Embodiment 1 to load and unload equipment that needs to be transported, the loading and unloading method is as follows:

[0051] (1) Transport the equipment that needs to be packaged into the first box 1 through the inlet and outlet 2, and fix the equipment with two pressure bars 3. When fixing, firstly press the pressure bar 3 and the first bolt 17 Pre-installation, make the two pressure bars 3 conflict with the opposite sides of the equipment, open the small door 13, set the first nut 7 on the end of the first bolt 17 through the operation window 6, and place the electric screwdriver 8 In the operating chamber 3.4, tighten the first nut 7 with an electric screwdriver 8 to realize the threaded fixation between the pressure bar 3 and the bottom plate 1.3. After fixing the equipment, close the small door 13 through the hasp 15, and pass the small door 13 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com