Adjusting device with a sealed guide cylinder

A technology for regulating devices and guiding sleeves, which is applied in the direction of valve devices, electromagnets with armatures, electromagnets, etc., which can solve problems such as lubricant escape, weakened sealing effect of seals, and jamming, and achieve large manufacturing tolerances Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

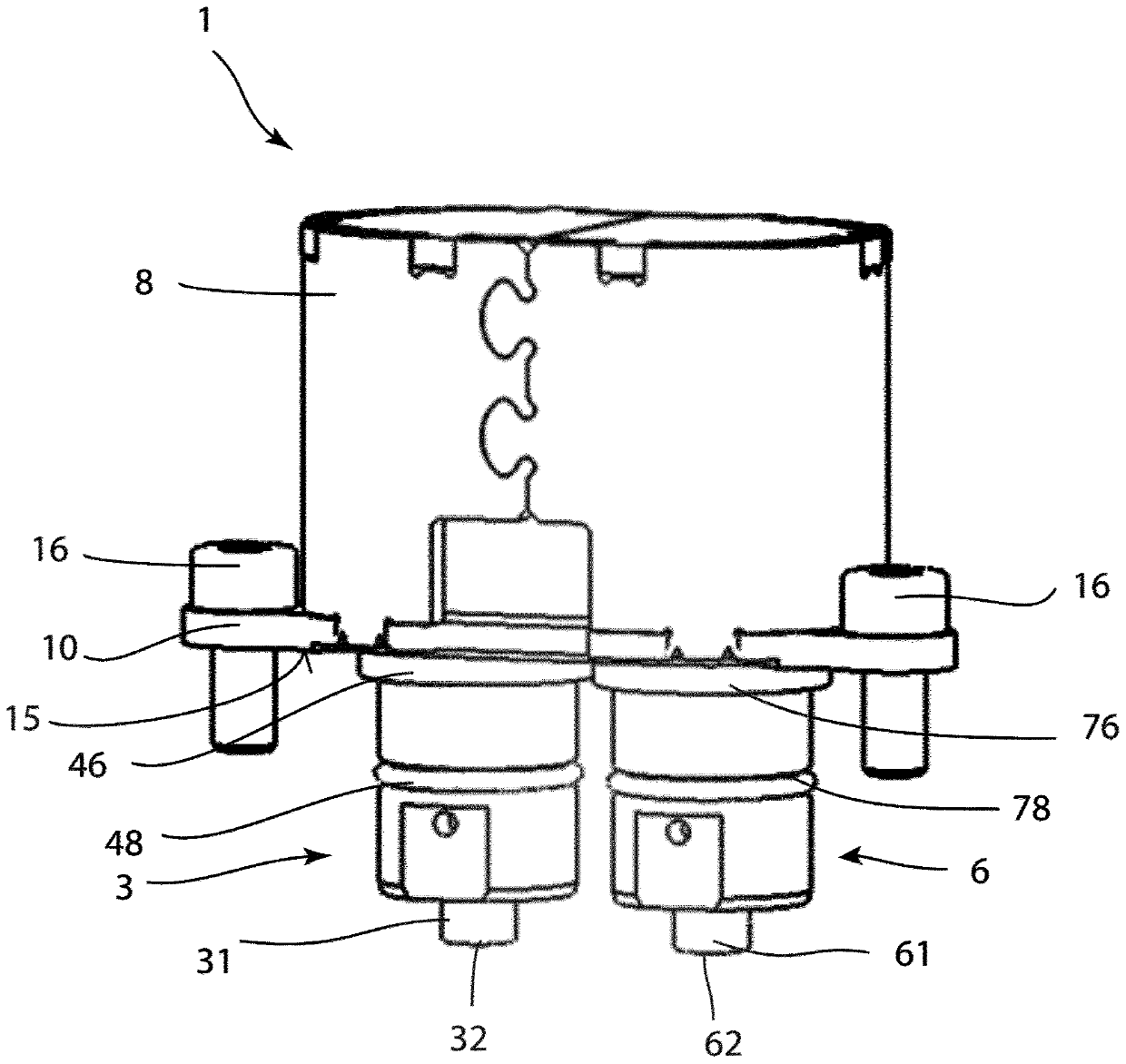

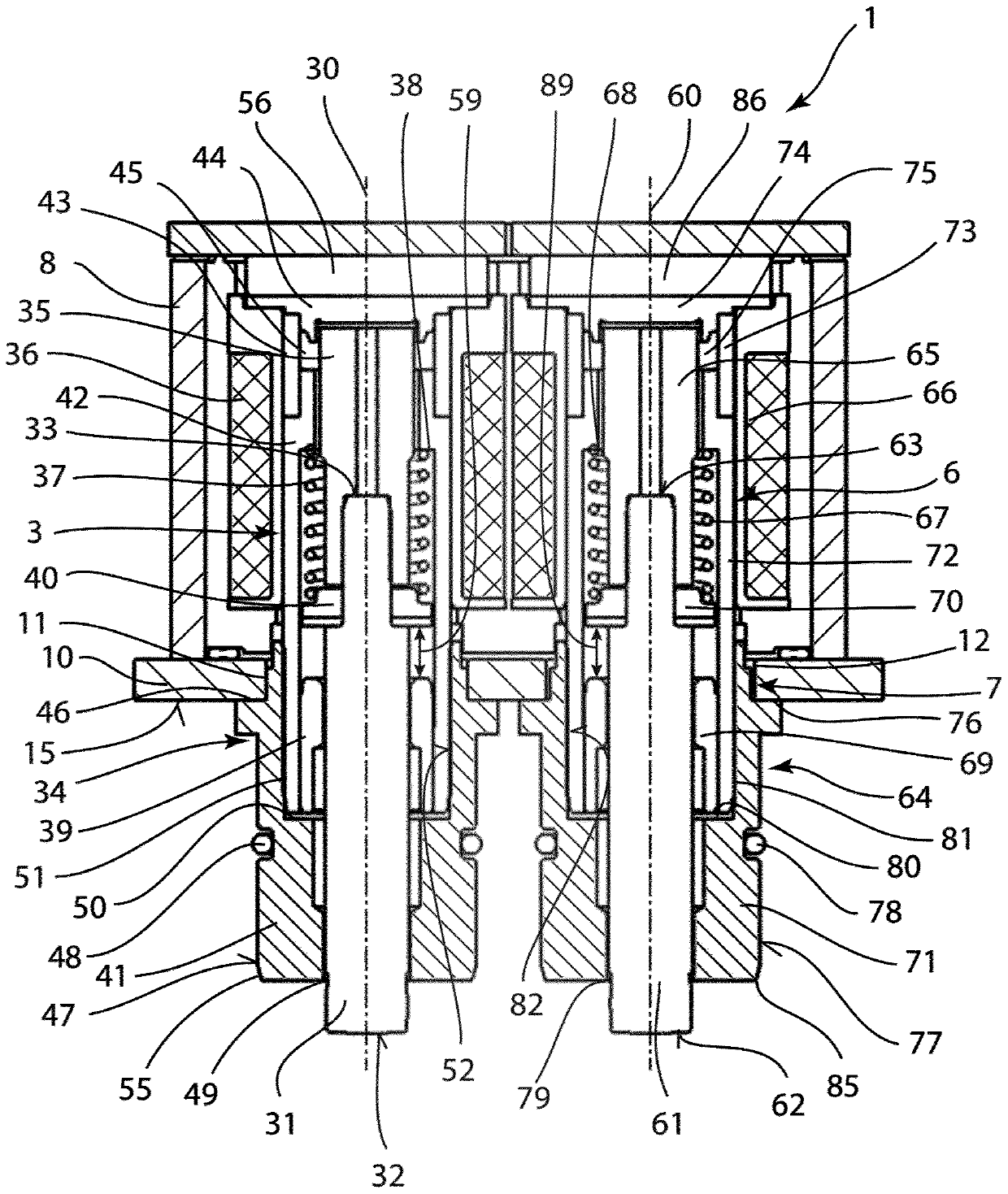

[0029] Refer below figure 1 and figure 2The adjusting device 1 according to a preferred embodiment of the present invention is described in detail.

[0030] figure 1 The adjusting device 1 is shown with a first tappet assembly 3 , a second tappet assembly 6 and a connecting plate 10 . A web 10 is provided for fixing the adjusting device 1 to a not shown camshaft housing. The lifter assemblies 3, 6 are substantially identical in structure and are parallel to and spaced apart from each other, and each lifter assembly 3, 6 comprises a lifter 31, 61 which moves longitudinally along the longitudinal axis 30, 60 The working strokes 59 , 89 are arranged in the respective guide cylinder 34 , 64 . exist figure 2 The working strokes 59 , 89 are shown by double arrows.

[0031] The respective tappet 31 , 61 has a front end 32 , 62 and a rear end 33 , 63 , the front end 32 , 62 protruding through a pilot cylinder opening 59 , 79 machined into the respective pilot cylinder 34 , 64 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com