Anti-corona tubular busbar drainage wire clamp with split structure

An anti-corona tube type and drainage wire clip technology, which is applied in the direction of cable suspension, welding/welding connection, etc. Improve anti-corona performance and current capacity, improve corona inception voltage, and solve the effect of small contact coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

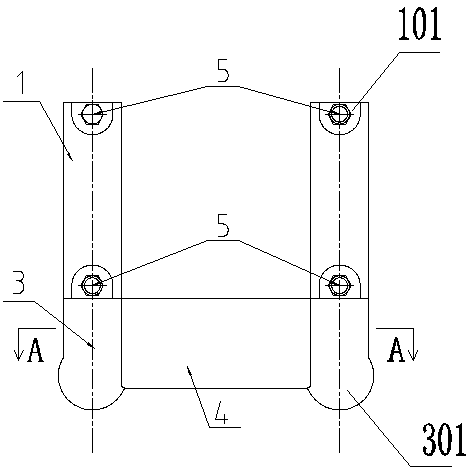

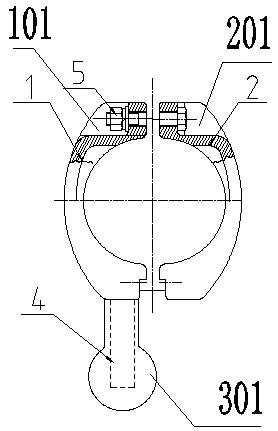

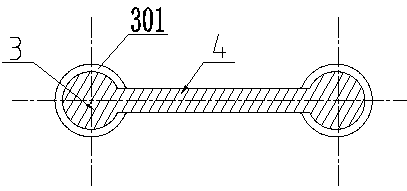

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings. like figure 1 , figure 2 and image 3 Shown: a split-structure anti-corona tubular busbar drainage clamp, including a fitting body 1 with a semicircular arc cavity, and a drainage terminal 4 at the lower part of the fitting body, which is fixedly connected to the fitting body 1 through bolts 5 There are two metal fittings cover plates 2 in the semi-circular arc cavity; the fitting body 1 and the fittings cover plate 2 are two, the drainage terminal 4 is a cuboid, and the left and right ends of the cuboid drainage terminal 4 are provided with anti-corona gardens Cylinder 3, two fitting bodies 1 are positioned at the upper end of anti-corona garden cylinder 3.

[0018] The two anti-corona cylinders 3 are welded together with the drainage terminals 4 to form a drainage terminal. The anti-corona cylinders 3 can prevent corona and avoid the discharge phenomenon, thereby...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com