GIL conductor three-post insulator crimping equipment

A technology of crimping equipment and insulators, which is applied in the field of GIL conductor three-pillar insulator crimping equipment, can solve the problems of high maintenance cost, many contact links, and high discharge rate, and achieve assembly quality, less contact links, and low discharge rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

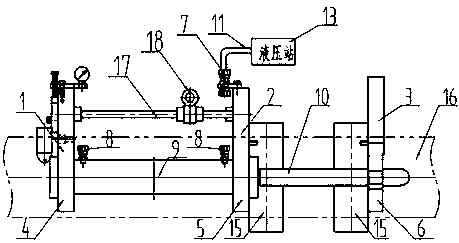

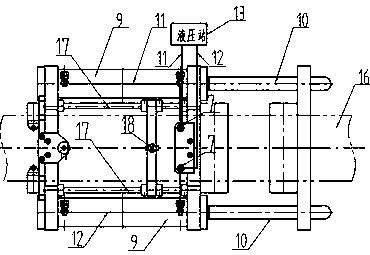

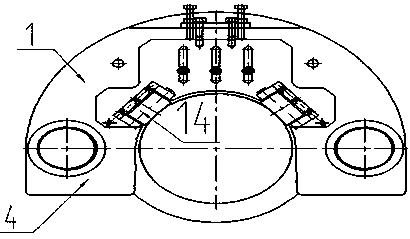

[0022] see Figure 1-3 , the present invention is a kind of crimping equipment for GIL conductor three-pillar insulators, comprising upper fixing plate 1, upper crimping plate (1) 2, upper crimping plate (2) 3, lower fixing plate 4, lower crimping plate (1) ) 5, the lower crimping plate (2) 6, oil cylinder 9, telescopic shaft 10.

[0023] The upper fixing plate 1 is connected together with the upper crimping plate (1) 2 through the tie rod 17, suspended above the conductor 16 to be crimped with the three-pillar insulator by means of the lifting ring 18, the three-pillar insulator is covered with the conductor 16, and the wedge-shaped block is inserted into the The three-post insulator is placed between the conductors 16 and the lifting ring 18 is lowered. The semicircle at the lower end of the upper fixing plate 1 and the upper crimping plate (1) 2 presses the edge of a pillar insulator.

[0024] Two oil cylinders 9 are symmetrically inserted into the upper fixing plate 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com