Knitted webbing wrapping splicing structure and weaving method thereof

A clad structure and clad technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve problems such as unevenness, affecting the effect of product fit, and easy exposure of sutures, so as to improve quality and firmness The effect of increasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

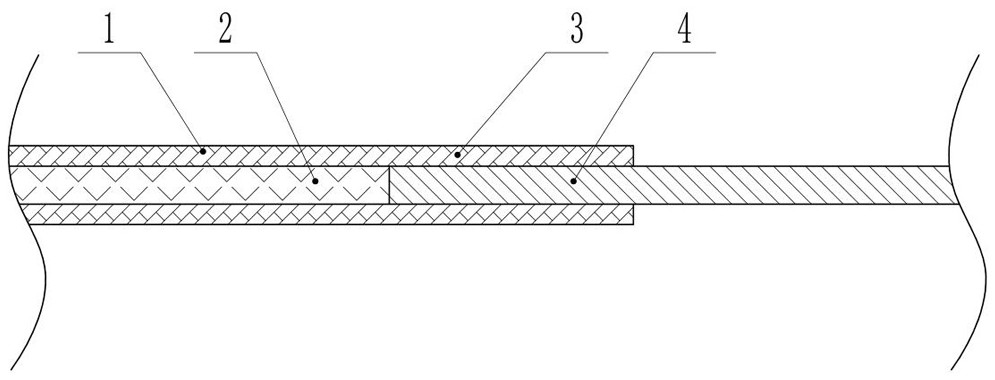

[0018] like figure 1 As shown, the knitted webbing covered splicing structure described in this embodiment includes a knitted webbing formed by two layers of coil layers, the knitted webbing includes a webbing portion and a connecting portion, the webbing portion is composed of at least two layers of coil layers 1, and passes The connecting yarns 2 are connected, and the connecting part is the upper and lower layered covering structure 3 composed of only the coil layer 1 . A connecting fabric 4 is inserted into the upper and lower layered covering structure 3 .

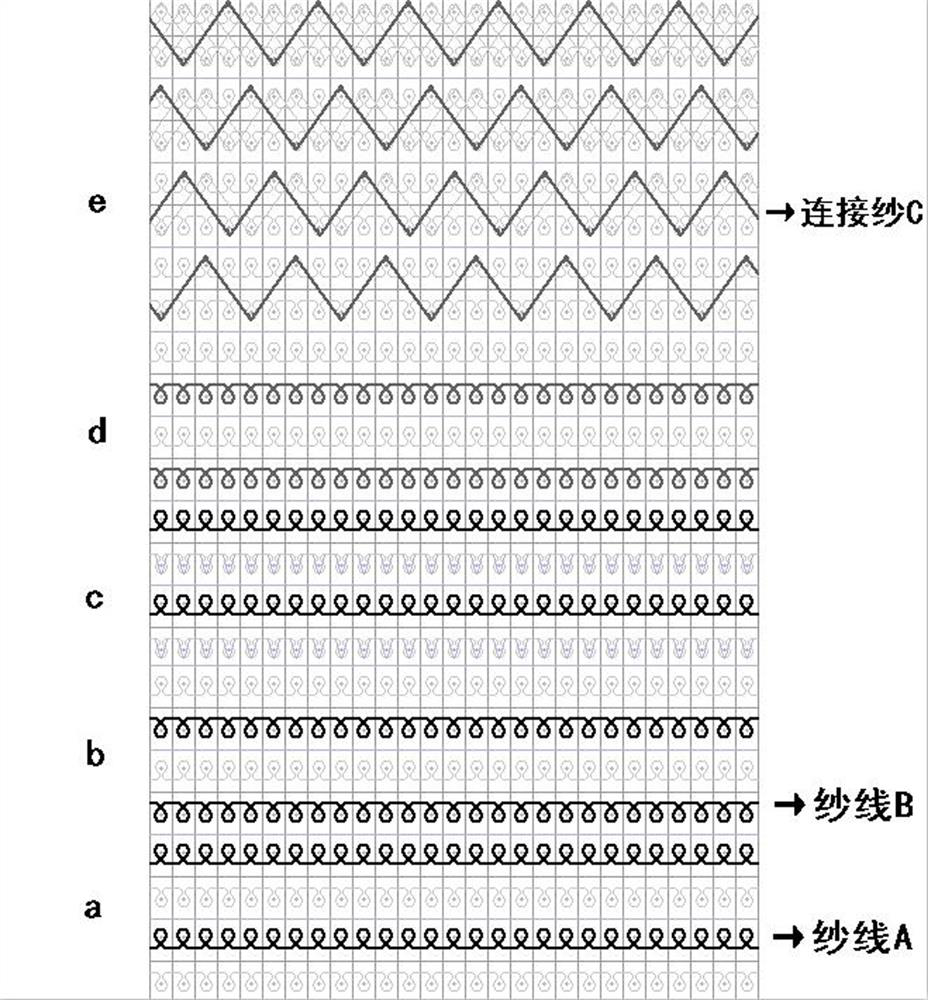

[0019] like figure 2 As shown, the knitting method of the above-mentioned knitted ribbon-covered splicing structure is to use three yarn feeders A, B and C on a flat knitting machine with a pair of front and rear needle beds extending in the left-right direction and facing each other in the front-rear direction according to the following steps Weave:

[0020] a) The right row of yarn A is used for back needle bed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com