Inorganic phase-change constant-temperature material and preparation method thereof

An inorganic phase change and constant temperature technology, applied in the direction of heat exchange materials, chemical instruments and methods, can solve problems such as degradation of thermophysical properties, and achieve the effects of good plasticity, simple process flow, and easy scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

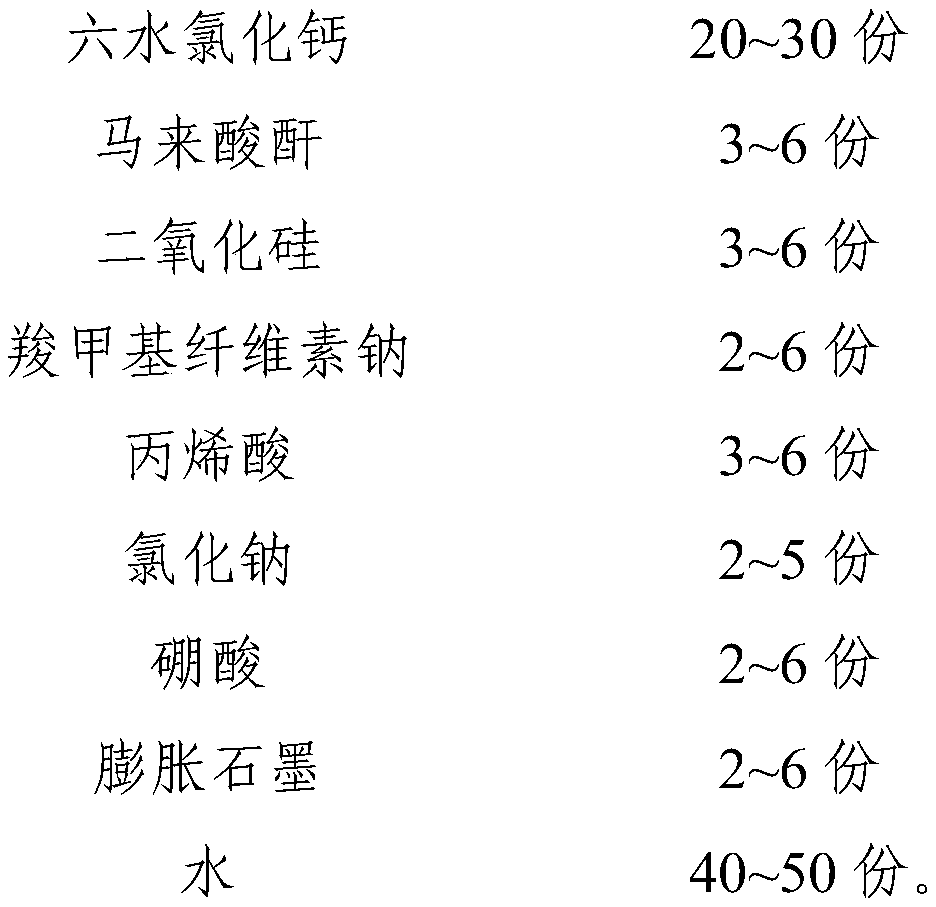

[0035] This embodiment provides an inorganic phase change constant temperature material, including the following components by weight:

[0036]

[0037]

[0038] The preparation method of the inorganic phase change constant temperature material is as follows:

[0039] (1) After mixing sodium carboxymethylcellulose and 10% water at 25-35°C, add maleic anhydride to obtain mixed solution I;

[0040] (2) Add silicon dioxide to the mixed solution I, then add 18% water, and react at 40° C. for 1 hour; obtain mixed solution II

[0041] (3) After mixing acrylic acid and 9% water, add sodium chloride to obtain mixed solution III;

[0042] (4) adding calcium chloride hexahydrate after mixing boric acid, expanded graphite, the mixed solution II and the mixed solution III, and reacting at normal pressure and 40° C. for 1 hour to obtain a polymer material;

[0043] (5) Mix the polymer material with the remaining part of water, and leave it for 10-15 minutes to obtain it.

[0044] ...

Embodiment 2

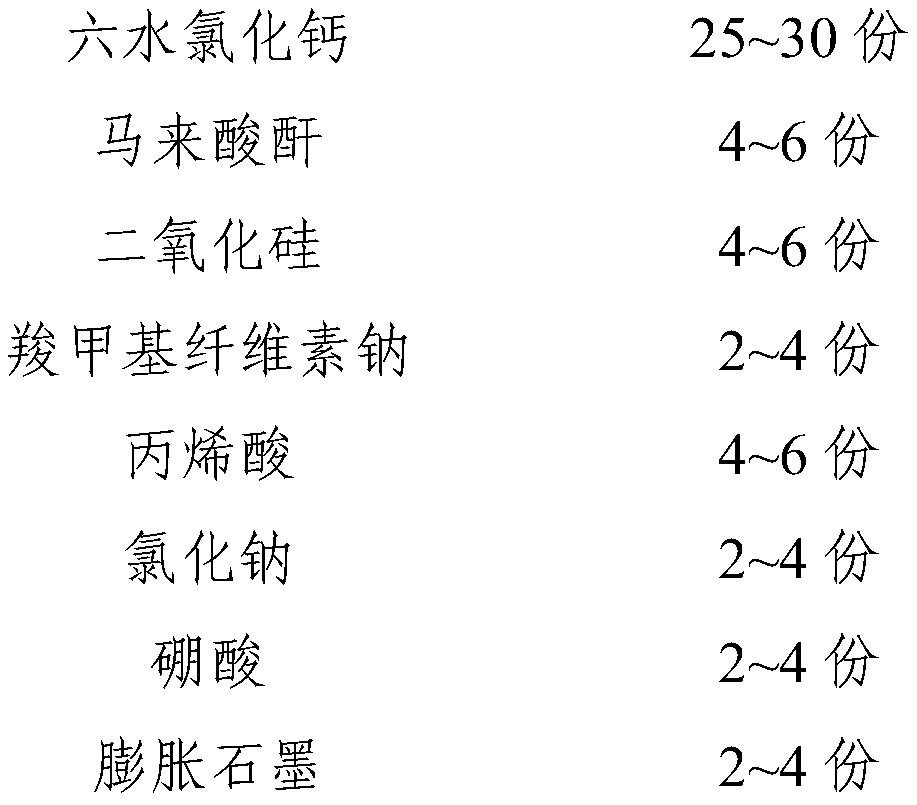

[0046] This embodiment provides an inorganic phase change constant temperature material, including the following components by weight:

[0047]

[0048]

[0049] The preparation method of the inorganic phase change constant temperature material is as follows:

[0050] (1) After mixing sodium carboxymethylcellulose and 9% water at 25-35°C, add maleic anhydride to obtain mixed solution I;

[0051] (2) Add silicon dioxide to the mixed solution I, then add 17% water, and react at 40° C. for 1 hour to obtain the mixed solution II;

[0052] (3) After mixing acrylic acid and 8% water, add sodium chloride to obtain mixed solution III;

[0053] (4) adding calcium chloride hexahydrate after mixing boric acid, expanded graphite, the mixed solution II and the mixed solution III, and reacting at normal pressure and 40° C. for 1 hour to obtain a polymer material;

[0054] (5) Mix the polymer material with the remaining part of water, and leave it for 10-15 minutes to obtain it.

[...

Embodiment 3

[0057] This embodiment provides an inorganic phase change constant temperature material, including the following components by weight:

[0058]

[0059]

[0060] The preparation method of the inorganic phase change constant temperature material is as follows:

[0061] (1) After mixing sodium carboxymethylcellulose and 8% water at 25-35°C, add maleic anhydride to obtain mixed solution I;

[0062] (2) Add silicon dioxide to the mixed solution I, then add 20% water, and react at 40° C. for 1 hour to obtain the mixed solution II;

[0063] (3) After mixing acrylic acid and 8% water, add sodium chloride to obtain mixed solution III;

[0064] (4) adding calcium chloride hexahydrate after mixing boric acid, expanded graphite, the mixed solution II and the mixed solution III, and reacting at normal pressure and 40° C. for 1 hour to obtain a polymer material;

[0065](5) Mix the polymer material with the remaining part of water, and leave it for 10-15 minutes to obtain it.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com