Ball screw-driven rigid and flexible coupling platform capable of adjusting rigidity externally

A ball screw, rigid-flexible coupling technology, applied in the field of motion platform, can solve problems such as difficulty in meeting industrial production needs, unfavorable industrial production efficiency, small working area of the working platform, etc., to increase the cost, increase the workable area, Replace simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

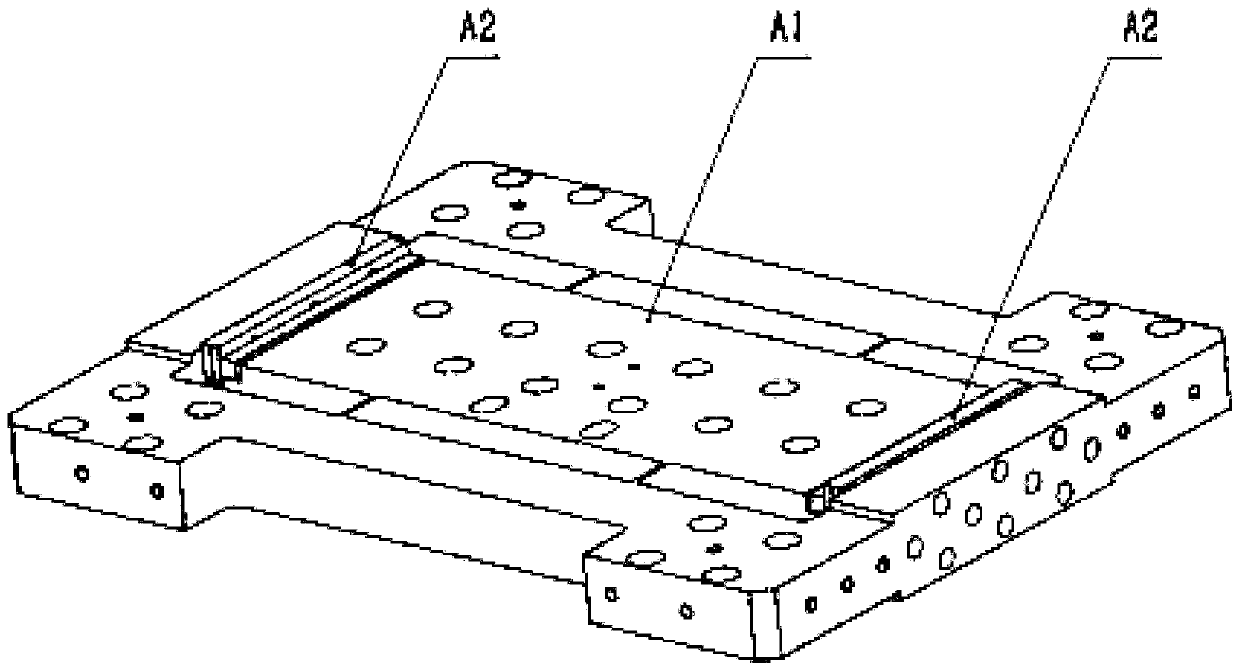

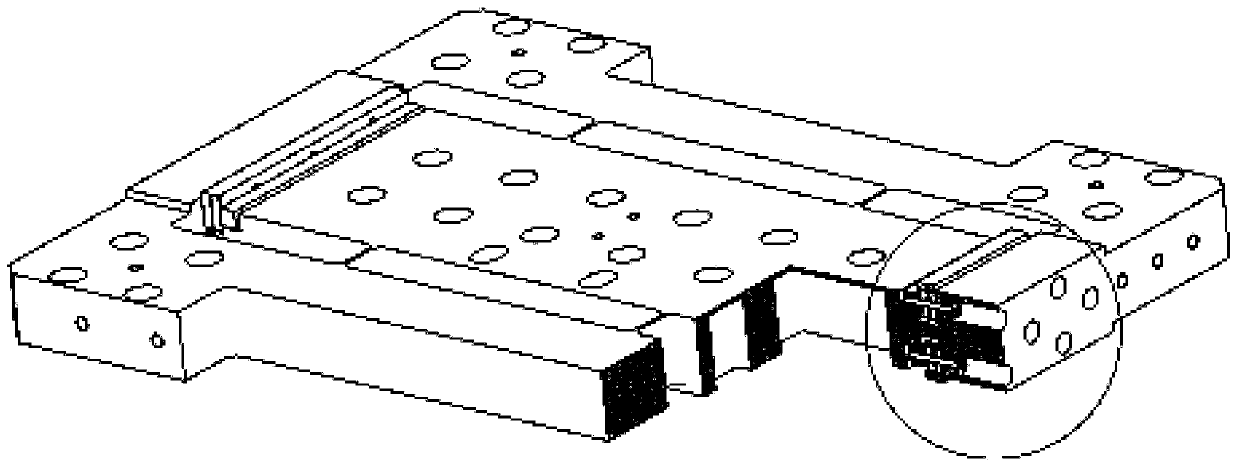

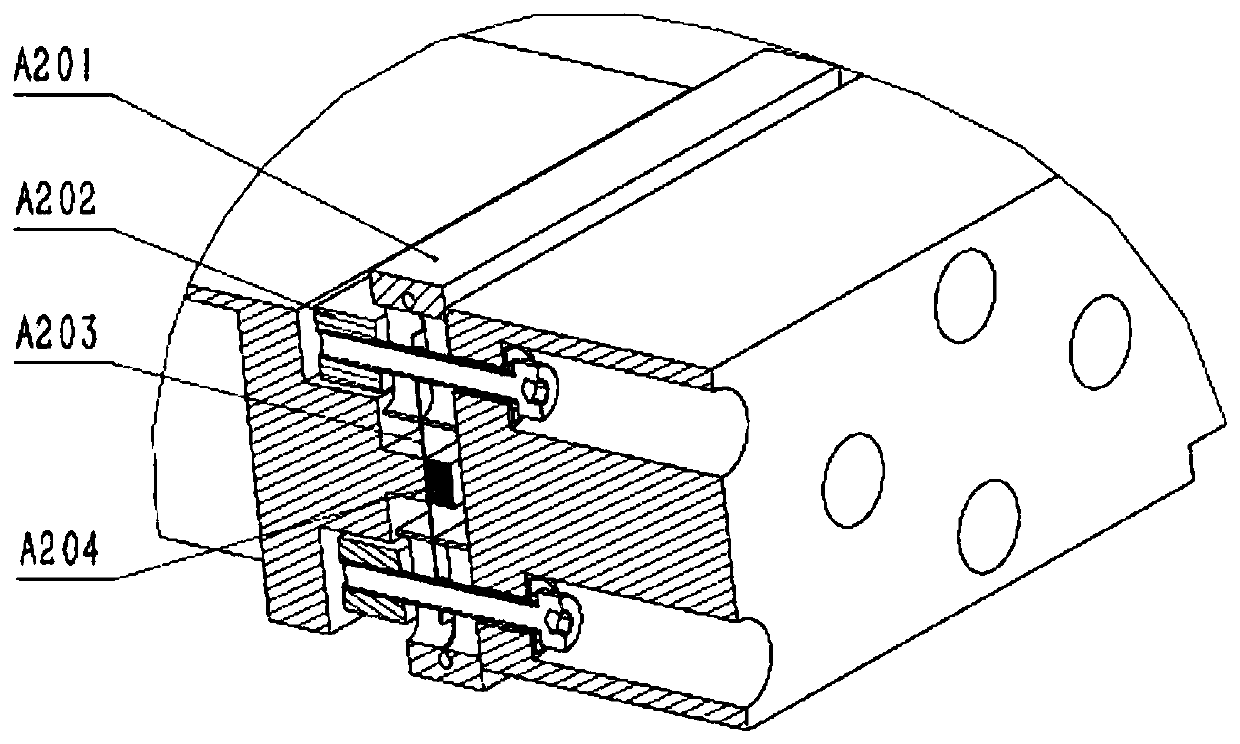

[0036] refer to Figure 7 to Figure 11 , this embodiment relates to a rigid-flexible coupling platform for external adjustment of rigidity driven by a ball screw, including a frame 1, a working platform 2 and at least two groups of flexible hinges 3, and each group of flexible hinges 3 is respectively arranged on two opposite sides of the frame 1 in the direction of the guide rail. On the end face; the working platform 2 is sleeved in the groove 11 of the frame 1, and the working platform 2 is not in contact with the frame 1; the two ends of the working platform 2 are fixedly connected with the flexible hinge 3, and the working platform 2 and the The nut 42 of the ball screw 41 is fixedly connected, and the main working direction of the flexible hinge 3 is the displacement direction of the working platform 2 .

[0037] The flexible hinges 3 in this embodiment are arranged in three groups. Three groups of flexible hinges 3 are respectively installed on the side of the frame 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com