Multi-angle-adjustable vertical rapid paint brushing device

A multi-angle, vertical technology, applied to the device and coating of the surface coating liquid, can solve the problem that the door body is not a flat structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

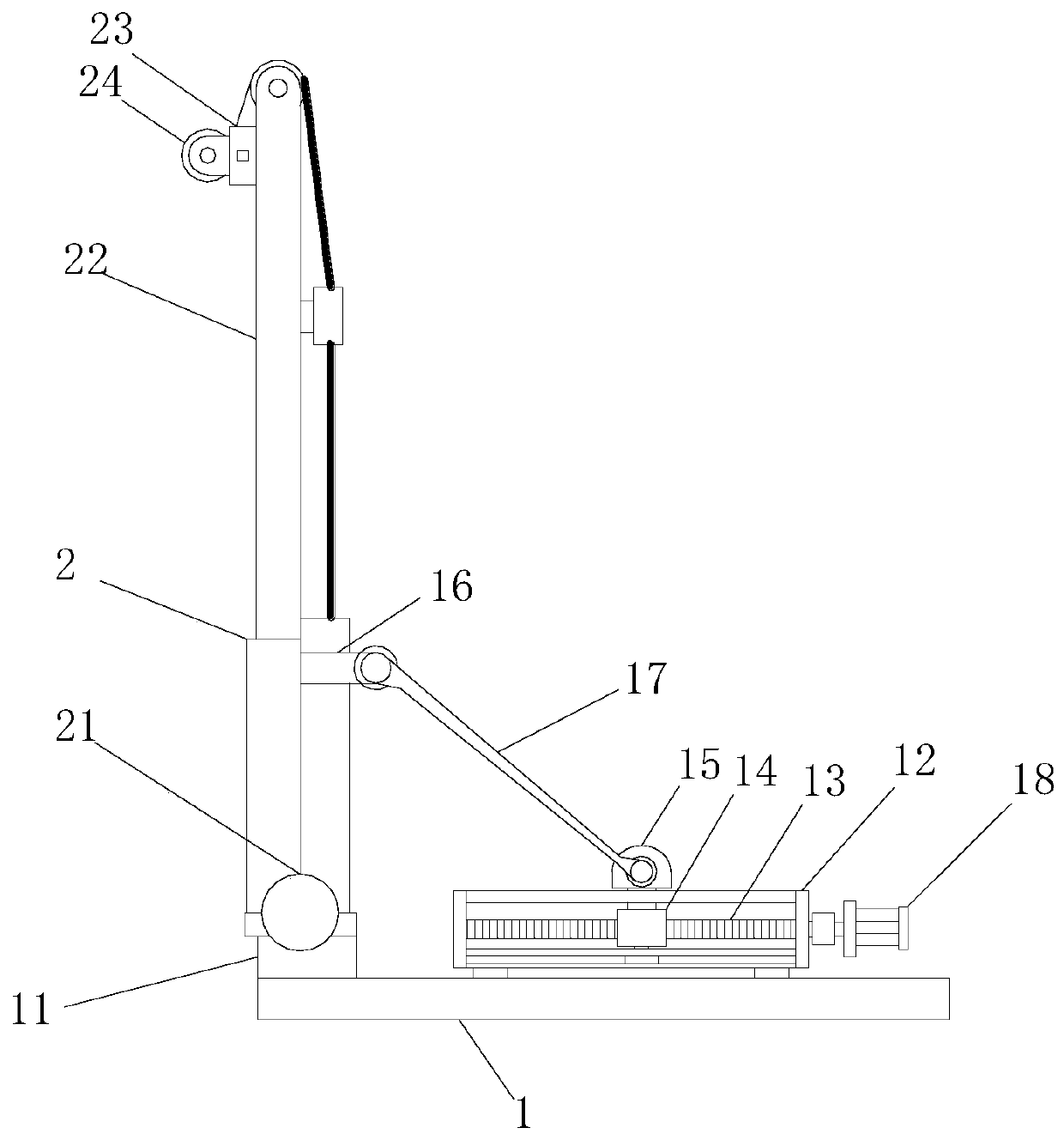

[0031] see figure 1 and figure 2 , a multi-angle adjustable vertical rapid painting device, including a vehicle seat 1 and a work frame 2, the front end of the vehicle seat 1 is equipped with a support seat 11, and the work frame 2 is installed on the support seat 11 through a movable rotating shaft 21 Above, the top of the work frame 2 is equipped with a support main rod 22, and the support main rod 22 is respectively installed on both sides of the work frame 2, and a vertical guide rail is opened on the front side wall of the support main rod 22, so that The supporting main rod 22 is movable with a lifting base 23 through the vertical guide rail, and a paint brush 24 is installed on the lifting base 23. The application frame 2 is installed on the vehicle seat 1 in a rotating shaft structure, and the paint brush 24 are movable up and down installations.

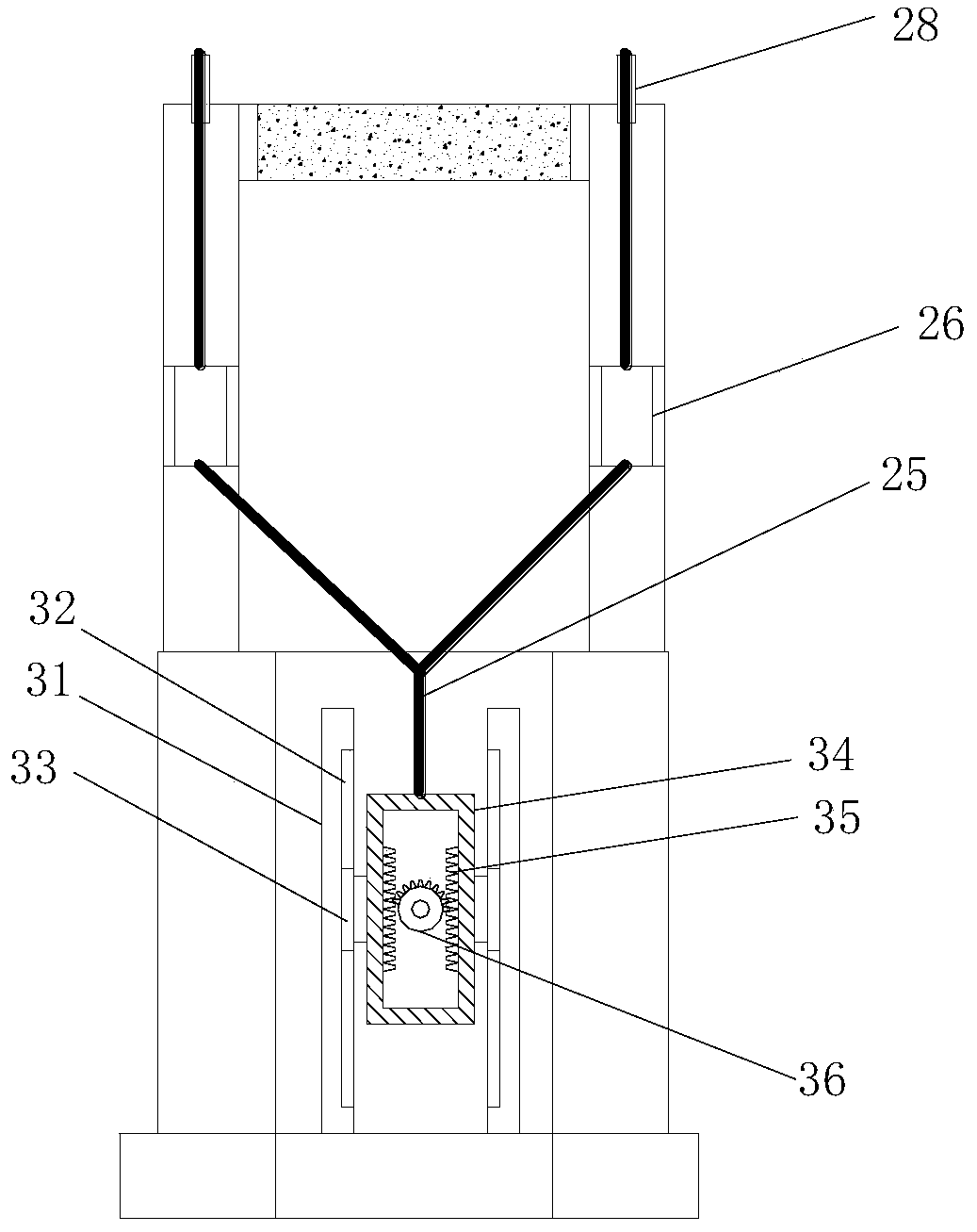

[0032] The rear side of described operation frame 2 is provided with transmission frame 31, and described transmission ...

Embodiment 2

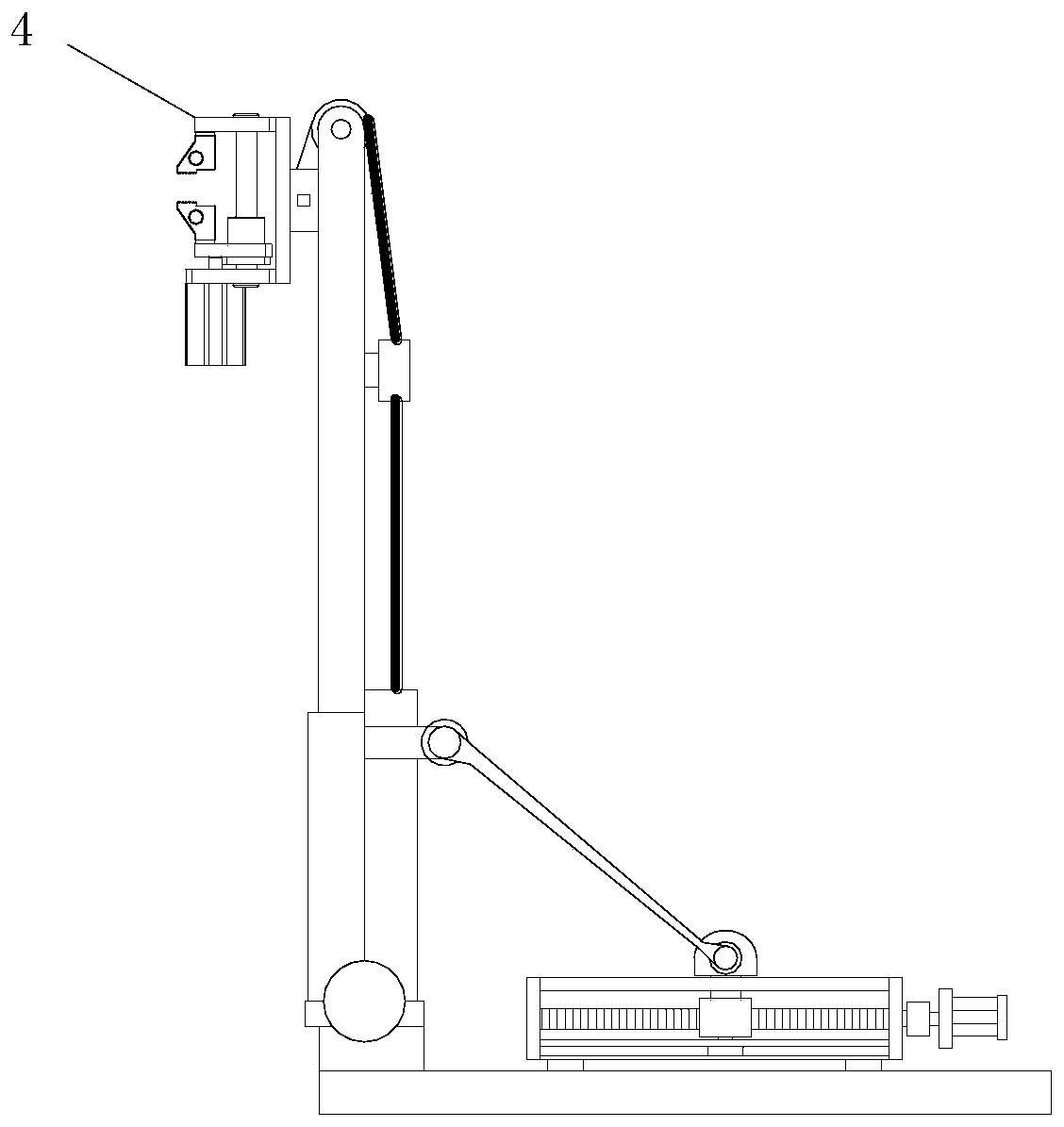

[0038] see image 3 , Figure 4 and Figure 5 , this embodiment is further optimized as Embodiment 1. On the basis of it, a brush holder 4 is installed on the lifting base 23, and the main body of the brush holder 4 is a concave frame 41, so The concave frame 41 is built with a fixed splint 42 and a movable splint 45, the fixed splint 42 is installed on the side wall of the concave frame 41 through the rear rod 43, and the movable splint 45 is movably installed on the concave frame through the slide bar 44. In the frame 41, the bottom of the concave frame 41 is equipped with a cylinder 46, the driving end of the cylinder 46 is equipped with a piston rod 47, and the rod end of the piston rod 47 extends into the concave frame 41 and a push plate 48 is installed , the push plate 48 is arranged directly behind the movable splint 45 . The inner side walls of the fixed splint 42 and the movable splint 45 are both provided with clamping lines 49 .

[0039] In view of the different ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com