A medium-temperature, moisturizing, yellowing and dense hanging rod baking method for middle and upper tobacco leaves

A curing method and technology for tobacco leaves, which are applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of insufficient degradation of protein and starch in tobacco leaves, the density of tobacco farmers' pack tobacco not meeting design requirements, and the reduction of oil content and aroma content in tobacco leaves. To achieve the effect of improving the coordination of chemical components, improving the quality of sensory evaluation and promoting full transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The tested flue-cured tobacco varieties of the present invention are Yunyan 87, Yunyan 85 and K326, and the parts and maturity balance of the tested tobacco leaves are basically the same.

[0048] 1. Experimental settings

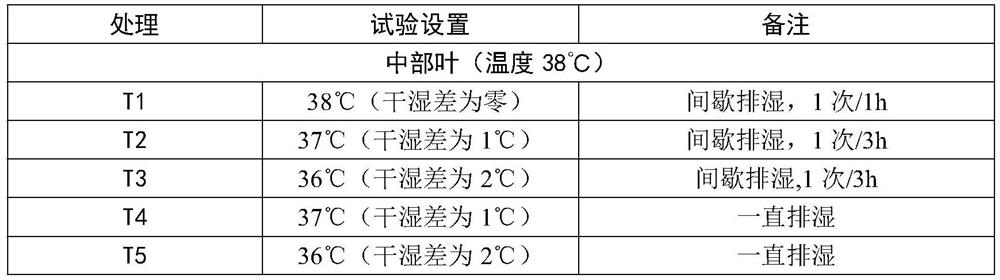

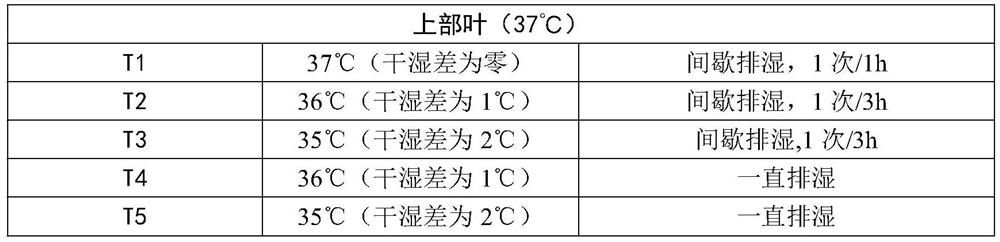

[0049] Set up experimental groups T1, T2, T3, T4, and T5 to explore the influence of wet bulb temperature on tobacco leaf quality during the main yellowing period of tobacco leaves.

[0050] Table 1 Different wet-bulb temperature treatment schemes during the yellowing period of the main body of tobacco leaves (37°C-38°C)

[0051]

[0052]

[0053] The above test was set at 37°C-38°C during the main yellowing period of the tobacco leaves. The dry bulb temperature was stabilized and different wet bulb temperatures were set until the tobacco leaves turned 80% yellow.

[0054] 2. Technical operation

[0055] T1 Baking Technology

[0056] Yellowing stage: start the fire steadily until the dry bulb temperature is 32°C-33°C, and the wet bulb temper...

Embodiment 2

[0115] The tested flue-cured tobacco varieties of the present invention are Yunyan 87, Yunyan 85 and K326, and the parts and maturity balance of the tested tobacco leaves are basically the same.

[0116] 1. Experimental settings

[0117] Three treatments were set up in the experiment: middle temperature and moisturizing intensive yellowing roasting T1, conventional roasting T2 and loose leaf roasting T3. See Table 12 for the specific settings. During the roasting process, samples were taken every 6 hours to measure the moisture, dry matter, starch, total sugar, reducing sugar, protein, amino acid, nicotine and other chemical components of the tobacco leaves, as well as the enzyme activities such as amylase and protein enzyme (enzyme activity was sampled to 120 ℃).

[0118] Table 12 Three baking method settings

[0119] deal with baking method Way of loading cigarettes operating technique T1 Moisturizing intensive yellowing baking at medium temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com