Rubber wheel bogie train wheel positioning method

A technology of train wheel and positioning method, which is applied in the direction of railway vehicle testing, etc., which can solve problems such as poor steering performance, wear of rubber tires, repeated detection process, etc., and achieve the effect of avoiding repeated detection and eliminating thrust angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

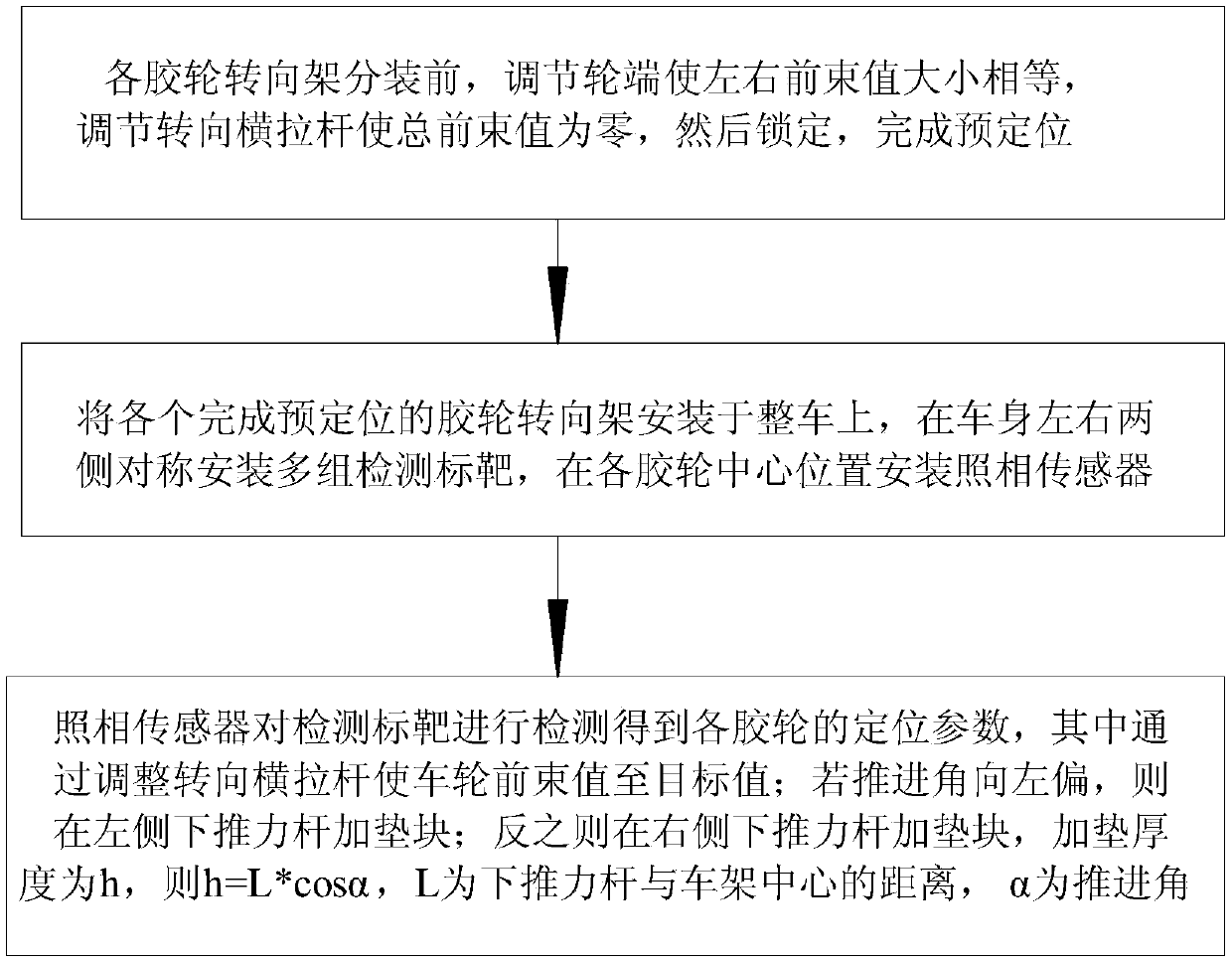

[0025] Figure 1 to Figure 5 Shown is an embodiment of the wheel alignment method for a rubber-tyred bogie train of the present invention. The wheel alignment method for a rubber-tyred bogie train of the present embodiment includes the following steps:

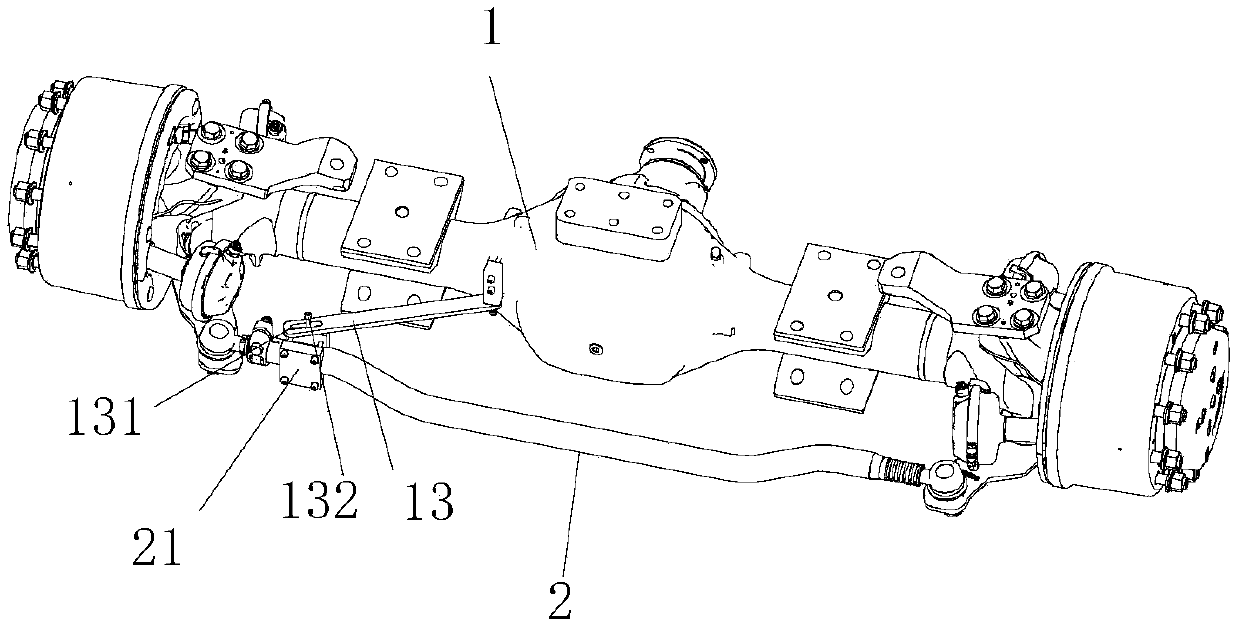

[0026] S1: Before each rubber wheel bogie 1 is assembled, adjust the wheel ends to make the left and right toe-in values equal, then adjust the steering tie rod 2 to make the total toe-in value zero, and finally lock it to complete the pre-positioning;

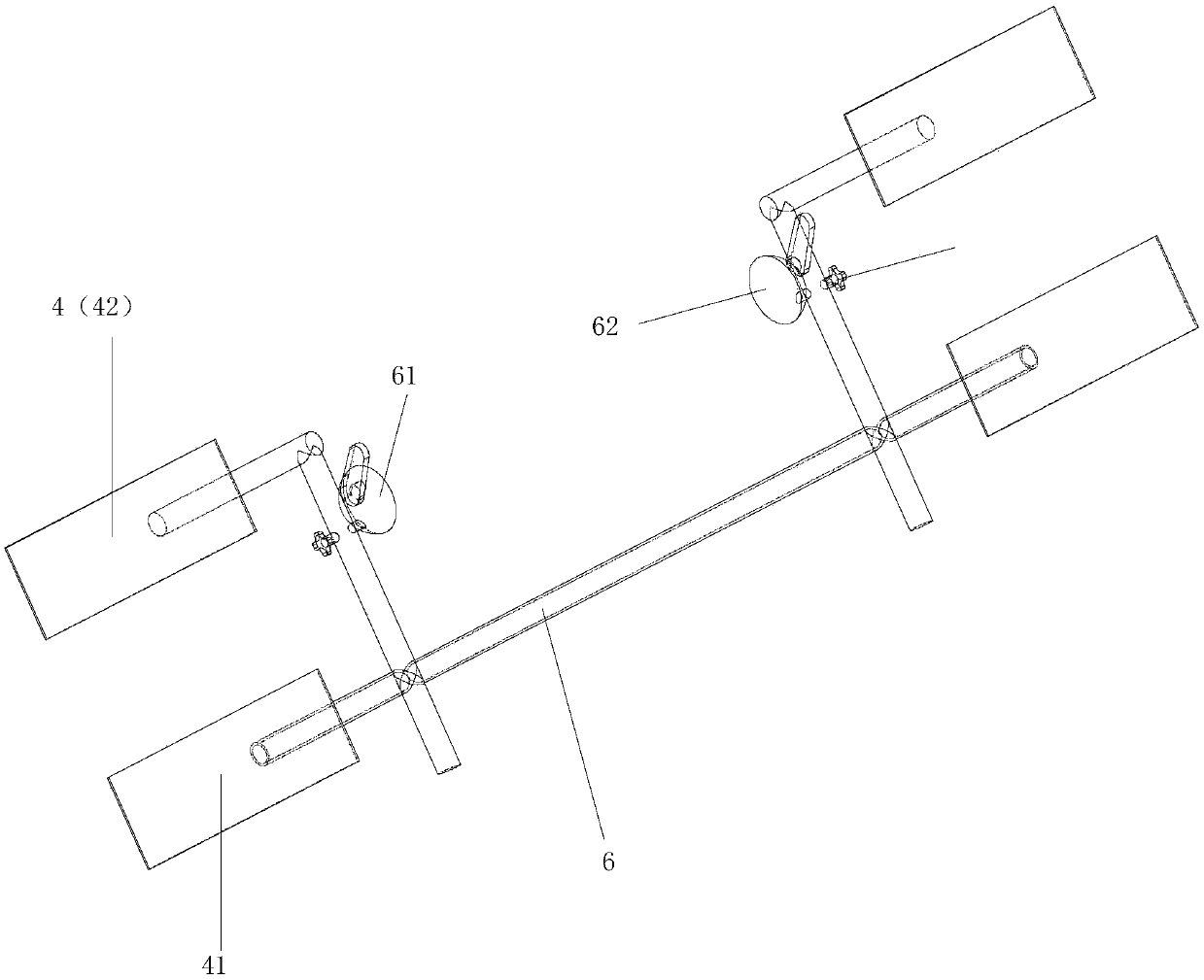

[0027] S2: Install each pre-positioned rubber wheel bogie 1 on the vehicle, install multiple sets of detection targets 4 symmetrically on the left and right sides of the vehicle body 3, and install a camera sensor at the center of each rubber wheel 5;

[0028] S3: The camera sensor detects the detection target 4 to obtain the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com