Conveying pipeline for sewage treatment

A technology for conveying sewage and conveying pipelines, which is applied in the sewer system, waterway system, pipeline system, etc., can solve problems such as hidden safety hazards, methane gas generation, and inconvenient cleaning of pipeline debris, and achieve the effect of avoiding cleaning and avoiding blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

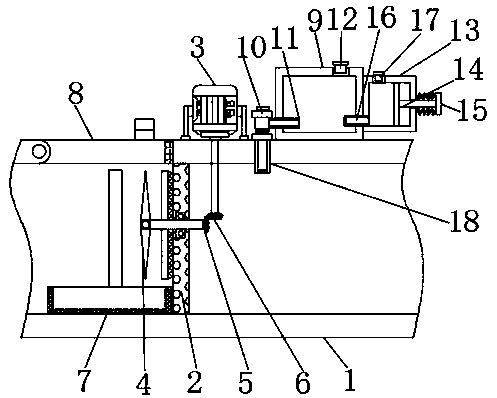

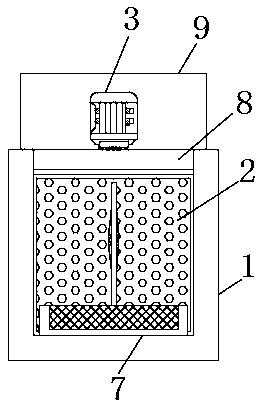

[0023] A conveying pipeline for sewage treatment, comprising a sewage conveying pipeline main body 1, a motor 3 and an air pump 10, an intercepting plate 2 is installed inside the sewage conveying pipeline main body 1, a motor 3 is installed on the top of the sewage conveying pipeline main body 1, and the motor 3 The output end extends through the main body 1 of the sewage conveying pipeline to the inside of the main body 1 of the sewage conveying pipeline and is welded and fixed with the second bevel gear 6. The model of the motor 3 is Y90S-2, and the left side of the intercepting plate 2 is provided with a crushing blade 4, and The right side of the crushing blade 4 passes through the intercepting plate 2 and extends to the right side of the intercepting plate 2 and is welded and fixed with the first bevel gear 5, and the crushing blade 4 is connected with the intercepting plate 2 through a bearing, the first bevel gear 5 and the second bevel gear The two bevel gears 6 are me...

Embodiment 2

[0025] The surface of the crushing blade 4 is sleeved with a brush rod, and the brush on the right side of the brush rod conflicts with the intercepting plate 2, and the top of the cleaning screen 7 is welded with a lifting rod, and the surface of the cleaning screen 7 is evenly provided with leakage holes , the interception plate 2 is scrubbed through the brush rod to avoid the blockage of the interception plate 2 by sundries, resulting in poor internal drainage, thereby reducing the drainage of the main body 1 of the sewage conveying pipeline, and then cleaning the leak holes on the surface of the mesh plate 7 to remove sewage and The sundries are separated, and the sundries are lifted up for cleaning;

Embodiment 3

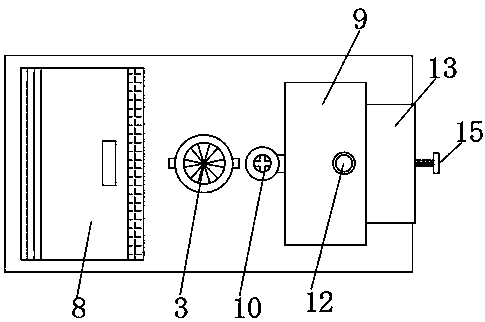

[0026] Embodiment 3: The upper and lower ends on the left side of the push plate 15 are connected to one end of the spring, the other end of the spring is connected to the brine tank 13, and the left side of the outlet pipe 16 passes through the absorption tank 9 and extends to the absorption tank 9 Inside, the left side of the liquid outlet pipe 16 is uniformly provided with a liquid outlet, and the spring drives the push plate 15 and the piston 14 to move to the left, pushing the brine in the brine tank 13 to move to the left, and then passes through the liquid outlet in the liquid outlet pipe 16. The liquid outlet slowly enters the interior of the absorption box 9, and the absorption rate of methane by the Span8080 solution is increased through brine.

[0027] Working principle: firstly, the user electrically connects the motor 3 and the control terminal of the air pump 10, and then connects the device to an external power supply, the motor 3 and the air pump 10 are started,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com