Split type valve with anti-seismic function

A split type, valve technology, applied in valve details, multi-way valves, valve devices, etc., can solve the problems of poor airtightness and reliability, and achieve the effect of improving airtightness, facilitating disassembly and maintenance, and strengthening airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

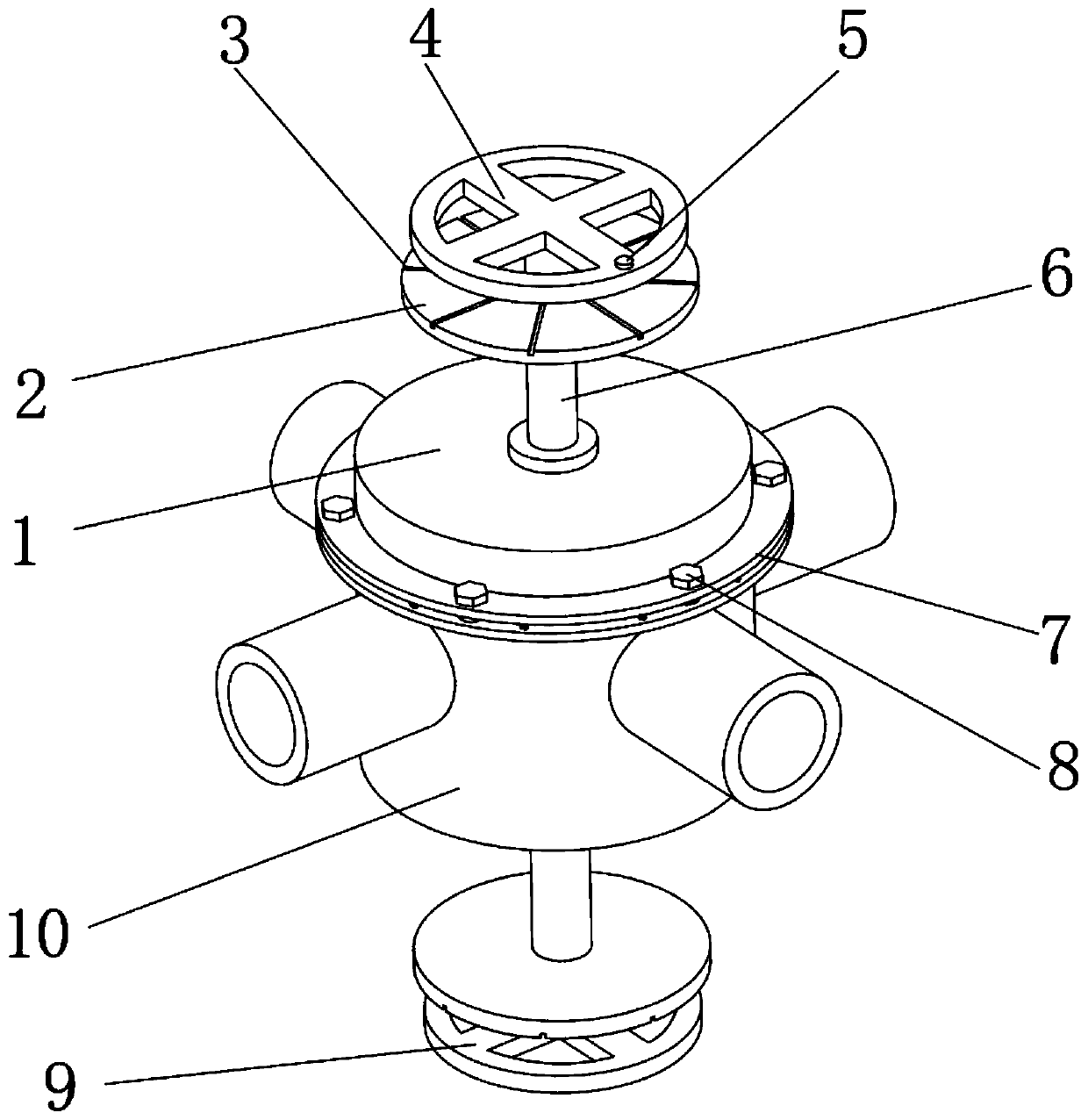

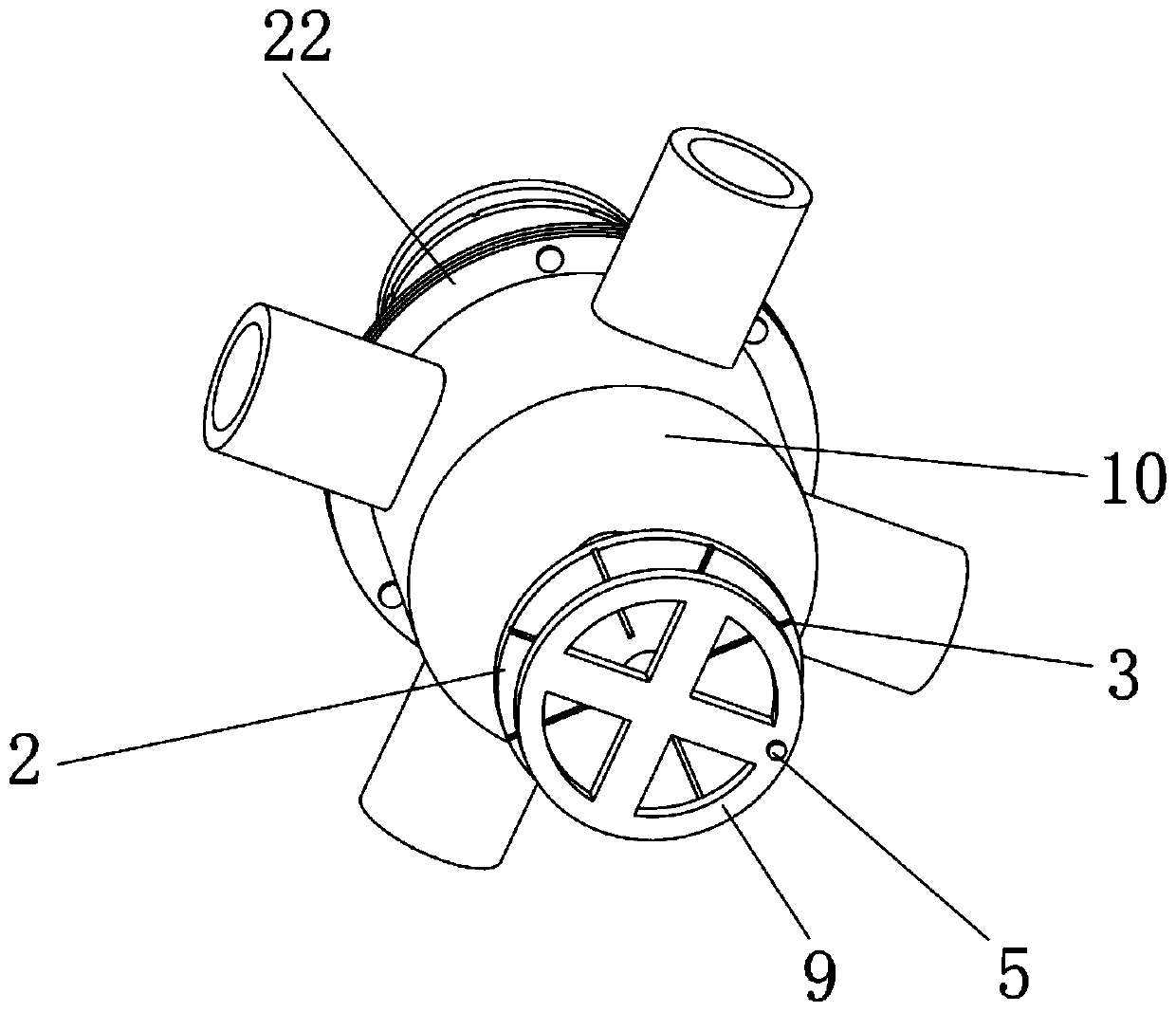

[0033] A split valve with anti-vibration function, such as figure 1 , Figure 4 , Figure 5 As shown, it includes a first valve body 1, a second valve body 10 and a conduction structure. The outer surface of the first valve body 1 is welded with a first connecting plate 7, and the outer surface of the second valve body 10 is welded with a second Connecting plate 22, the inner wall of the first connecting plate 7 and the inner wall of the second connecting plate 22 are connected with the same group of uniformly circumferentially distributed locking bolts 8 by threads; the outer wall of the top of the first valve body 1 and the second valve body 10 Two bearing blocks 25 are respectively fixed on the outer wall of the bottom of the bottom by screws, two control shaft seats 6 are respectively fixed on the outer walls of the two bearing blocks 25 by screws, and two control shaft seats 6 are slidingly connected on the inner walls of the two control shaft seats 6 respectively. One ...

Embodiment 2

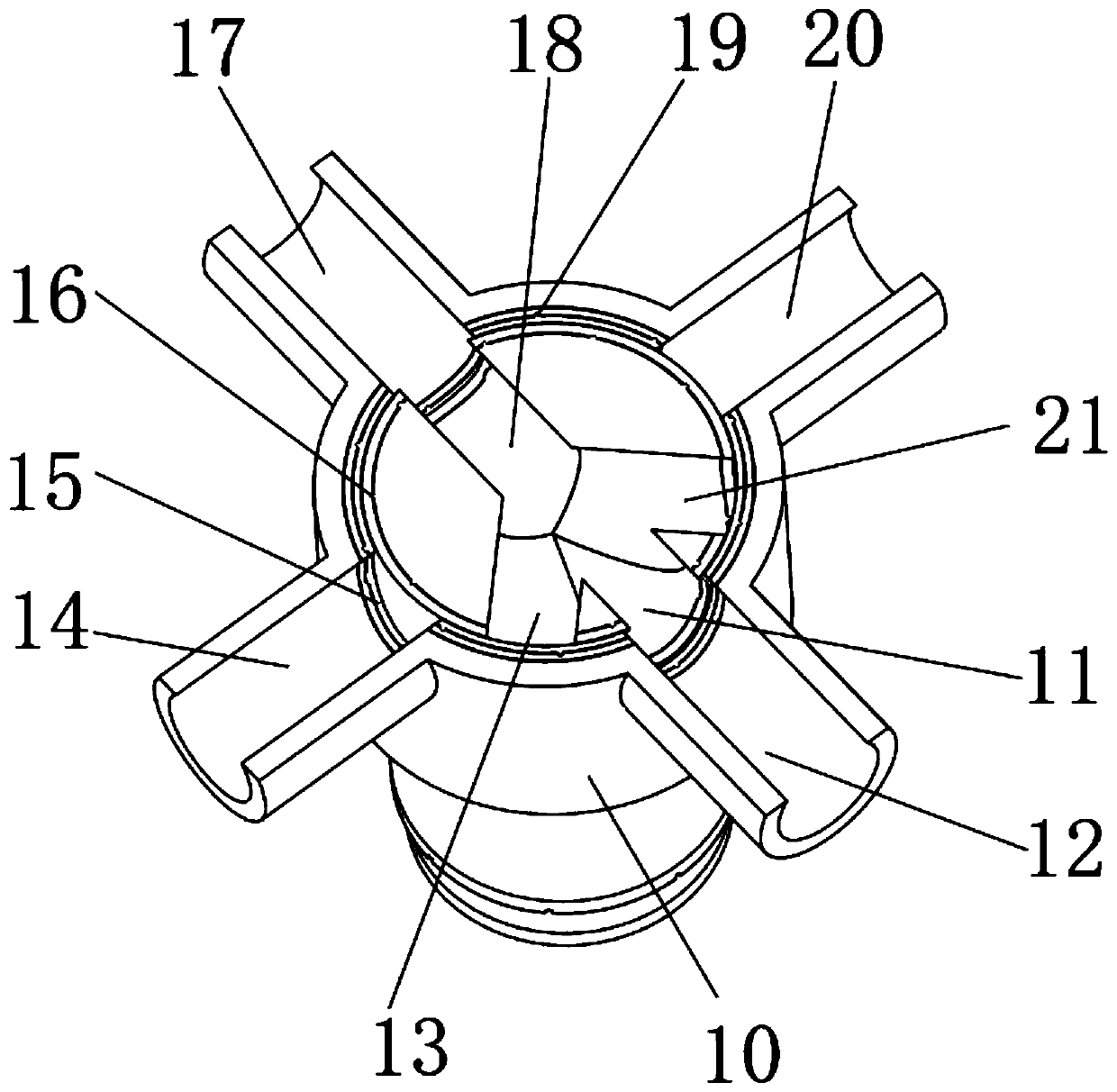

[0044] A split valve with anti-vibration function, such as figure 2 As shown, in order to solve the problem of firmness between the sealing layer and the valve core; this embodiment makes the following improvements on the basis of Embodiment 1: the outer surface of the first valve core 23 is provided with first protrusions uniformly distributed around the circumference 16, the outer surface of the second valve core 28 is provided with second protrusions 19 uniformly distributed around the circumference.

[0045] When this embodiment is in use, the first protrusion 16 can increase the contact area between the first sealing layer 27 and the first valve core 23, thereby increasing the firmness of the connection between the two; the second protrusion 19 can increase the second sealing The contact area between the layer 29 and the second valve core 28 increases the firmness of the connection between the two.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com