Connecting valve facilitating vacuum pumping and vacuum breaking

A technology for connecting valves and breaking vacuum, which is applied in the direction of lifting valves, valve details, valve devices, etc., can solve the problems of not being able to break the vacuum of the suction cup, restrict the direction of ventilation, and not suitable for applications, etc., to achieve convenient implementation, reduce energy consumption, and structure compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

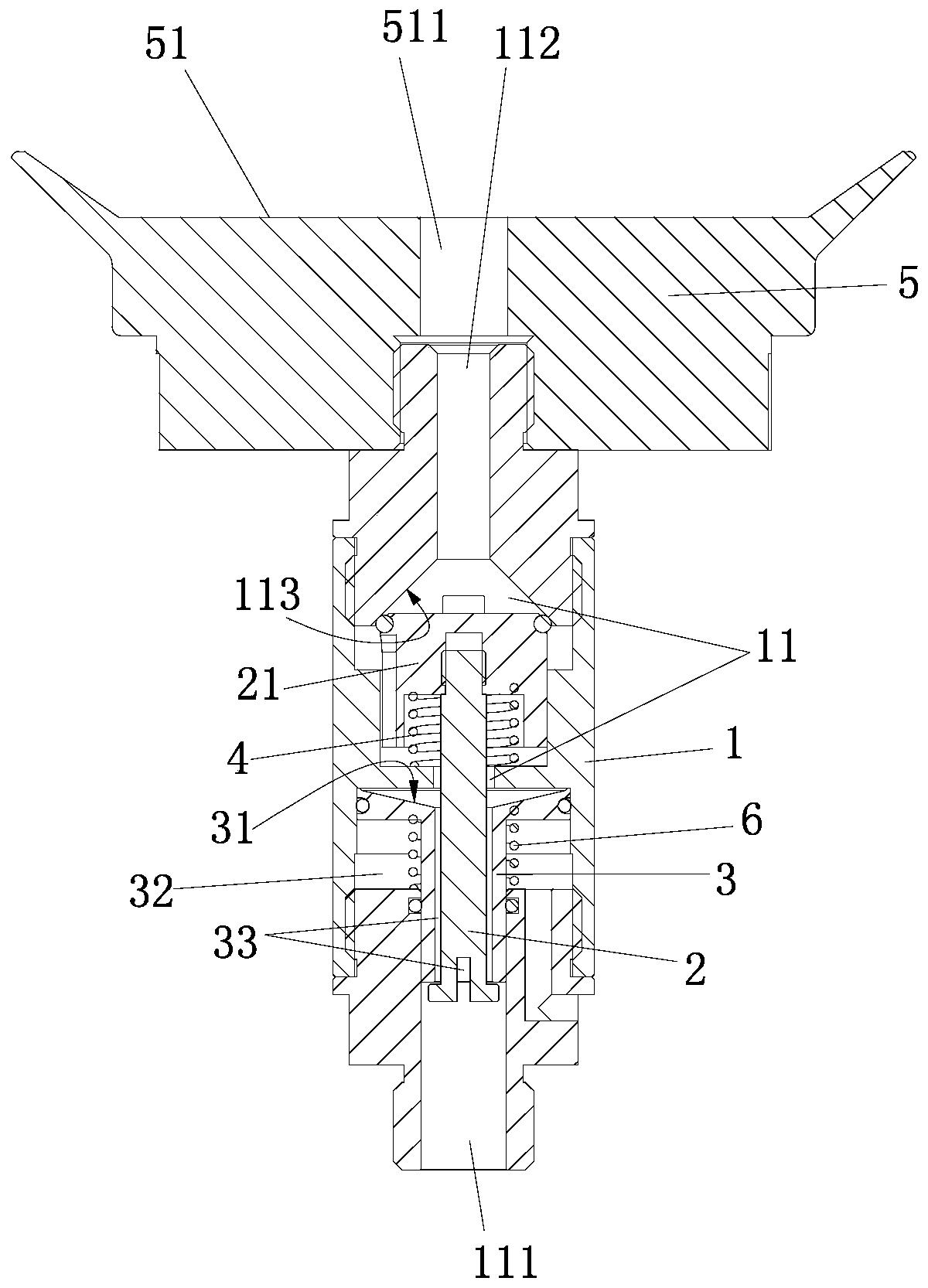

[0028] In Embodiment 1, the air suction port 111 is located on the wall of the connecting valve 1 between the sealing structure and the driving member 3, so that the driving member 3 does not make any contact between the air suction port 111 and the driving member 3. The passage of airflow between the sealing structures forms an obstacle, and the passage of airflow is convenient.

Embodiment 2

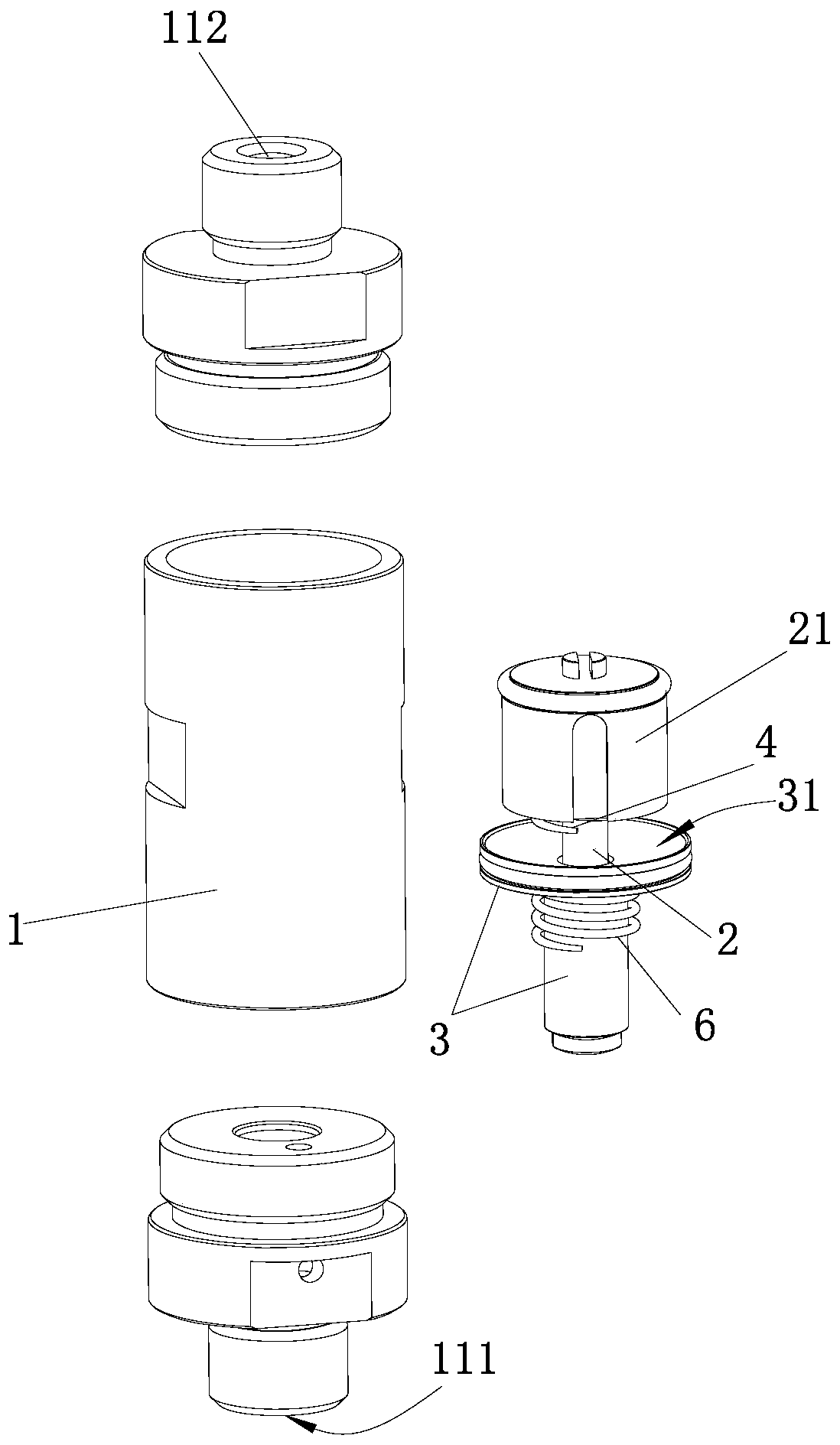

[0029]Embodiment 2, the air extraction and delivery port 111, the driving part 3, the sealing structure, and the object connection port 112 are set in sequence, and the driving part 3 is set on the movable part at the end close to the air extraction and delivery port 111 to prevent falling off. 2, a cavity 32 is formed between the outer wall of the driving member 3 and the inner wall of the connection valve 1, which is not connected to the air suction port 111, and the force-bearing surface 31 faces away from the air suction port 111. In the driving part 3 or in the moving part 2 or between the driving part 3 and the moving part 2, there is a passage for the air flow between the suction and air supply port 111 and the sealing structure. space33.

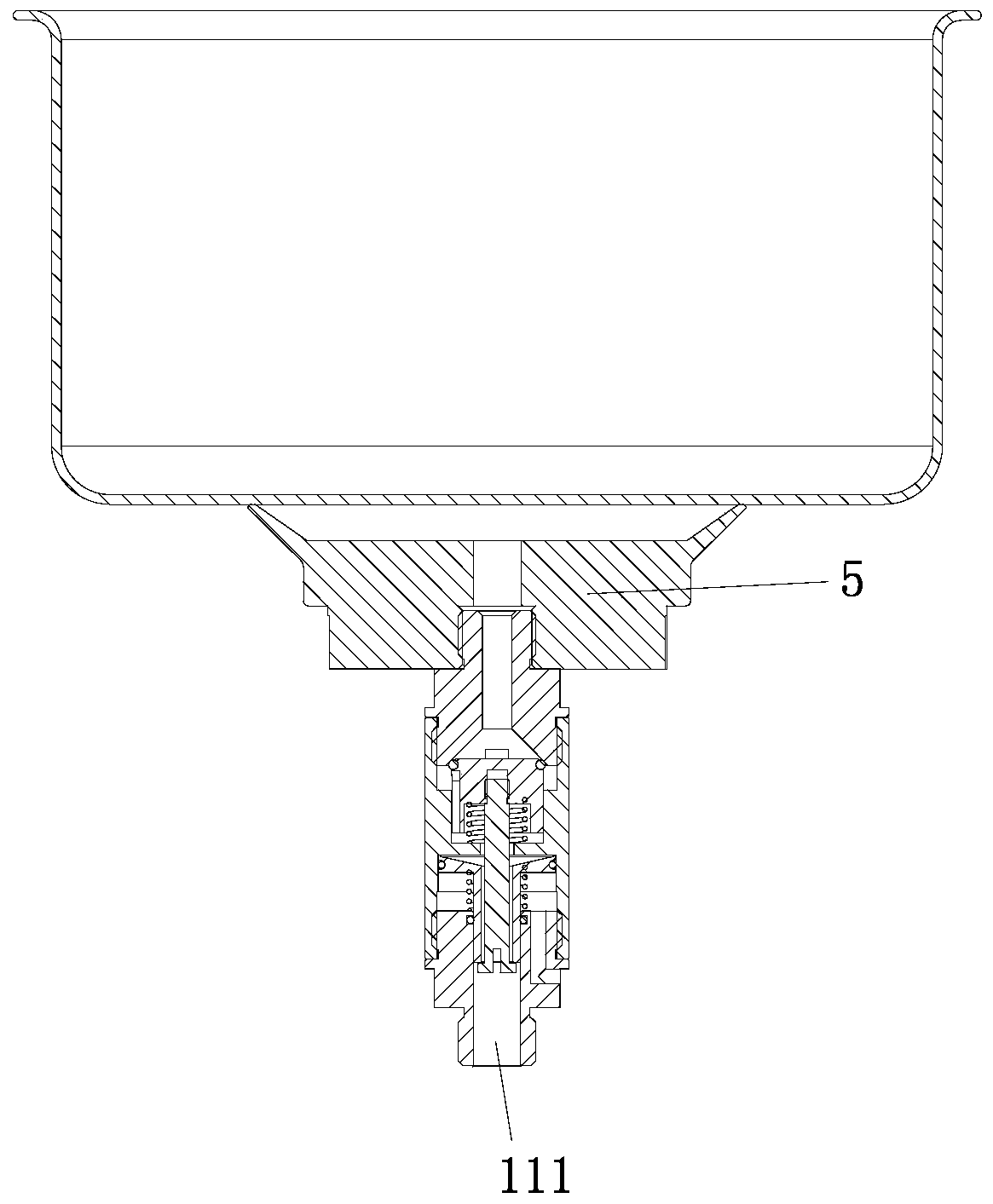

[0030] As mentioned above, the air extraction port 111, the driving member 3, the sealing structure, and the object connection port 112 described in this case are arranged in sequence. both ends, such as image 3 As shown, it is su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com