Installation device for sealing strip of automobile radiator

A technology of automobile radiator and installation device, which is applied in metal processing, metal processing equipment, manufacturing tools and other directions, can solve the problem of not being able to ensure that the sealing strip is pressed tightly, affecting the sealing performance of the radiator, etc., and achieves good installation effect and production cost. Low, reasonable and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

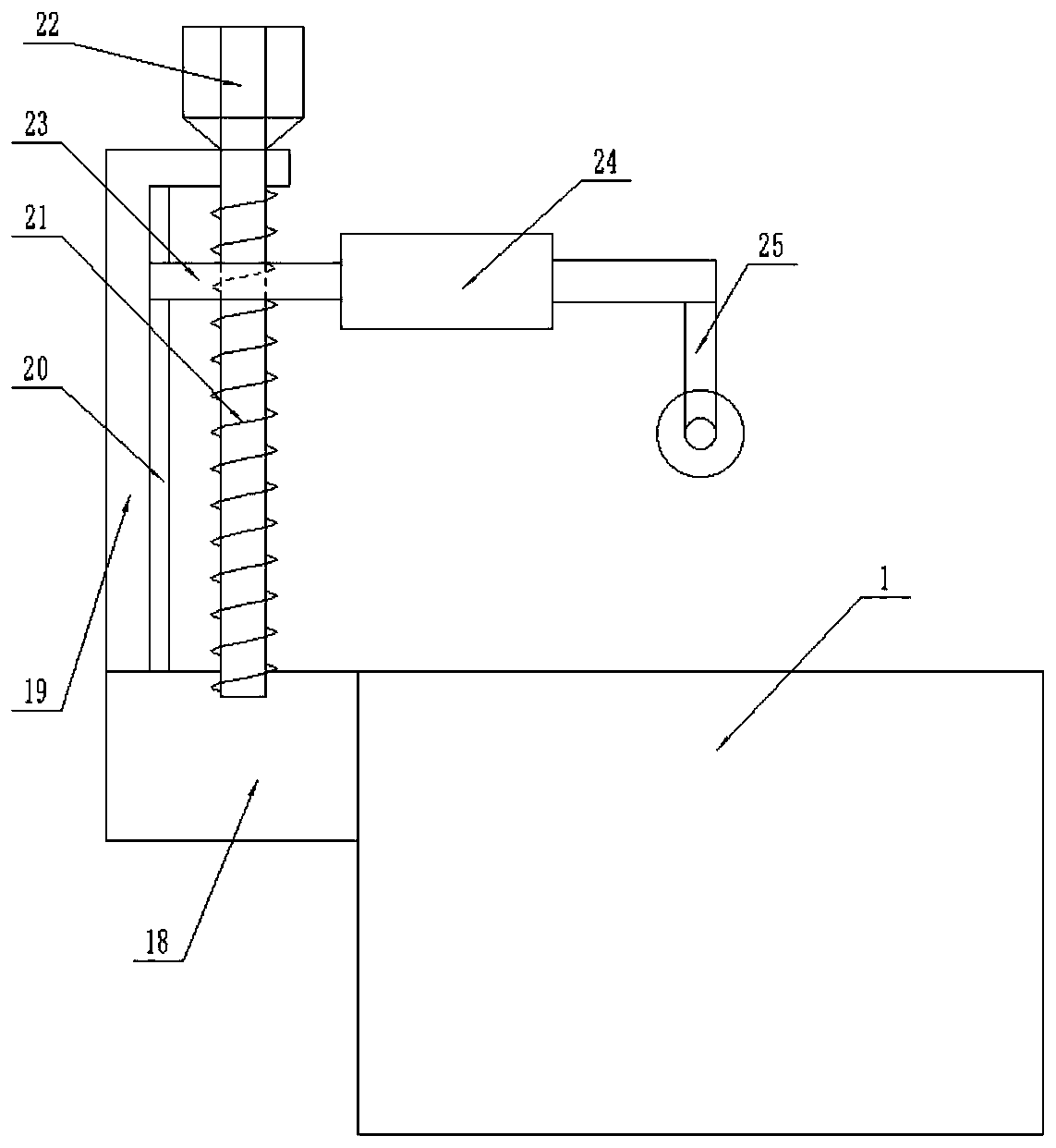

[0021] like Figure 1 to Figure 4 As shown, this specific embodiment adopts the following technical solutions: a kind of installation device of automobile radiator sealing strip, including frame 1, installation rod 2, first motor 3, gear 4, right rack 5, right vertical rod 6, Right buffer 7, right clamping plate 8, left rack 9, left vertical rod 10, left buffer 11, left clamping plate 12, mounting seat 18, cover 19, slide rail 20, lead screw 21, second Motor 22, slide block 23, pneumatic cylinder 24 and pressure roller group 25; The chamber wall on the left side of described frame 1 is fixedly connected with mounting rod 2, and the first motor is fixedly connected on the right side end of described mounting rod 2 3. A gear 4 is fixedly connected to the output end of the first motor 3; a left rack 9 is slidably connected to the upper left end of the frame 1, and a right rack 5 is slidably connected to the lower end of the right side of the frame 1, The right rack 5 and the lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com