A stamping, bending and punching die

A bending and die technology used in the stamping field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

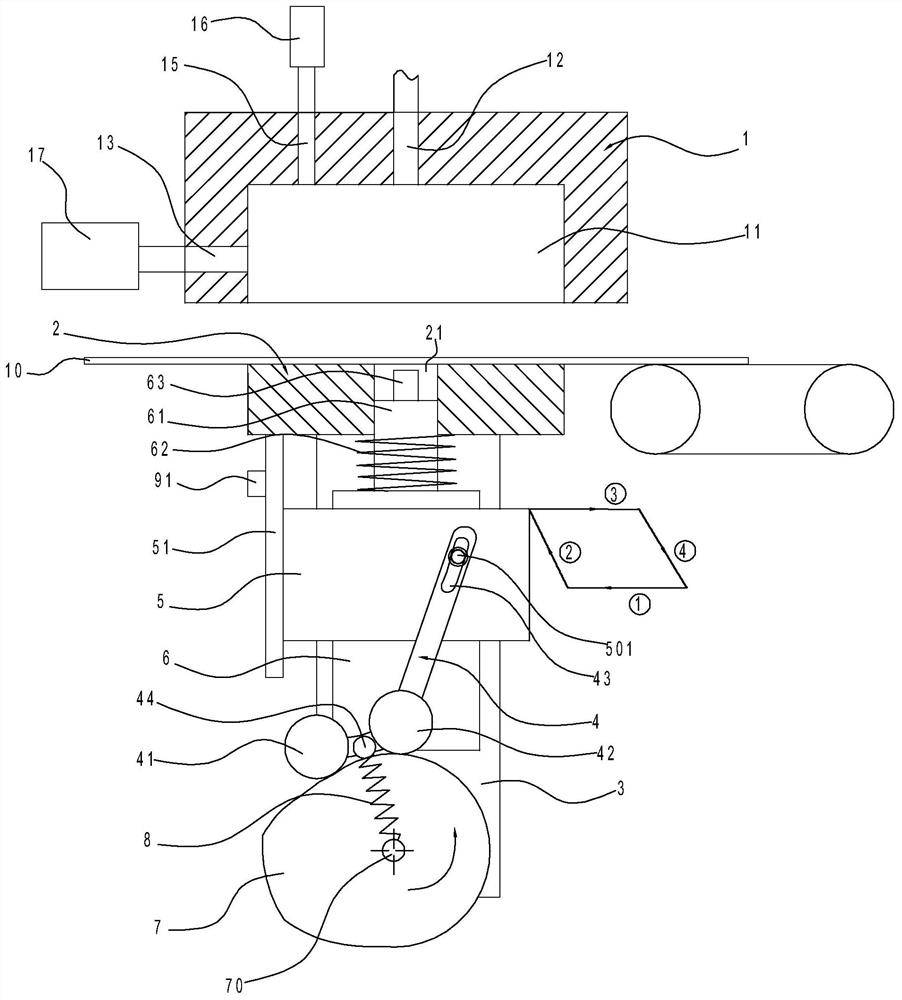

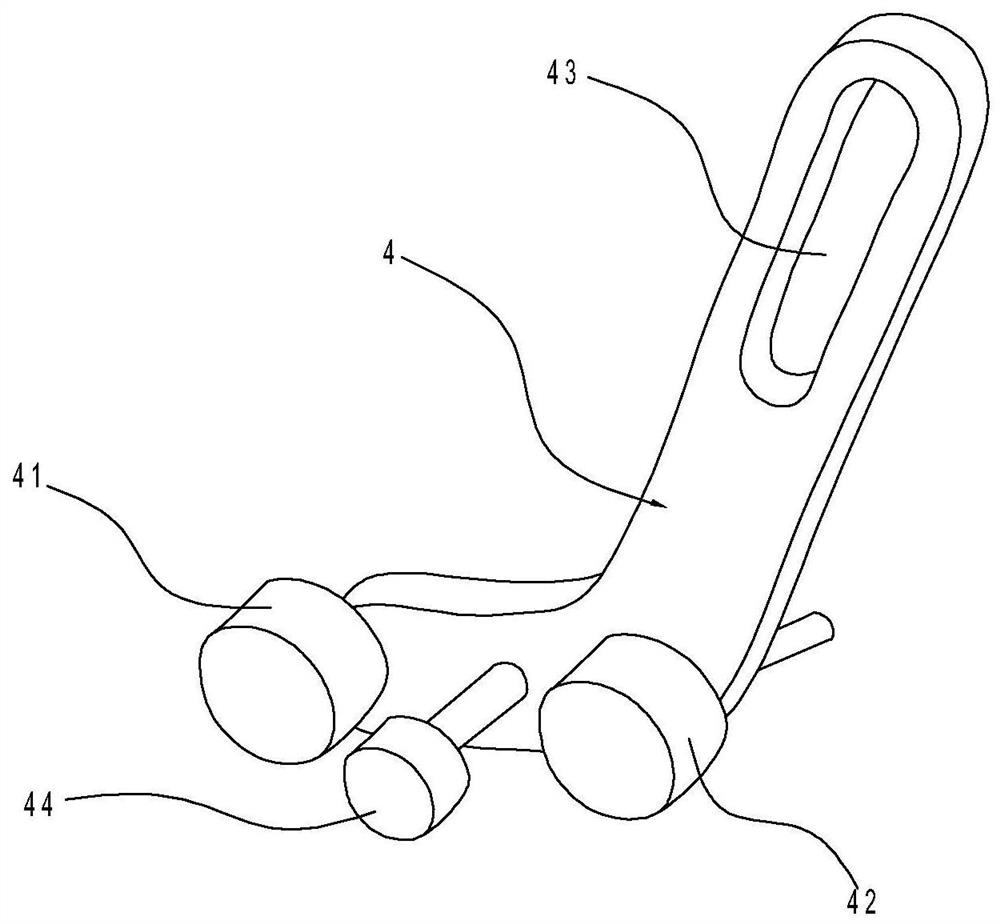

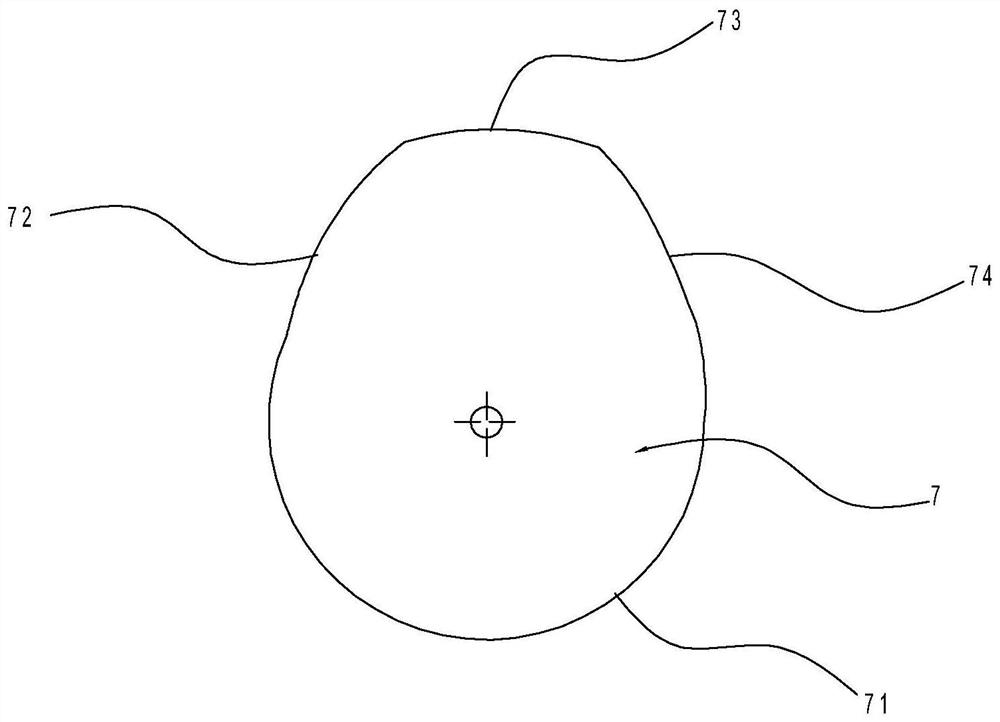

[0026] Such as Figures 1 to 8 As shown, the stamping, bending and punching die in this implementation includes an upper die 1, a lower die 2, a driving cam 7, a fixed plate 3, a horizontal slide plate 5, a vertical slide plate 6, a bending rod 4, a first roller 41, a Two rollers 42, hold down spring 8, support rod 51, left punch 91, stamping spring 62, upper punch 63, suction pump 17 and blowing pump 16.

[0027]Wherein, the upper die 1 is fixedly arranged, and the lower die 2 is set in motion, and the upper die 1 is formed with a cavity 11 with a downward opening for carrying out U-shaped bending to the plate 10, and on the bottom of the cavity 11 An upper punching hole 12 is provided, a left punching hole 13 is provided on the left side wall of the cavity 11, a right punching hole 14 is provided on the right side wall of the cavity 11, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com