Suction cleaning device with chamber cover with locking device

A technology of locking device and cleaning equipment, applied in cleaning equipment, suction nozzles, vacuum cleaners, etc., can solve problems such as high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

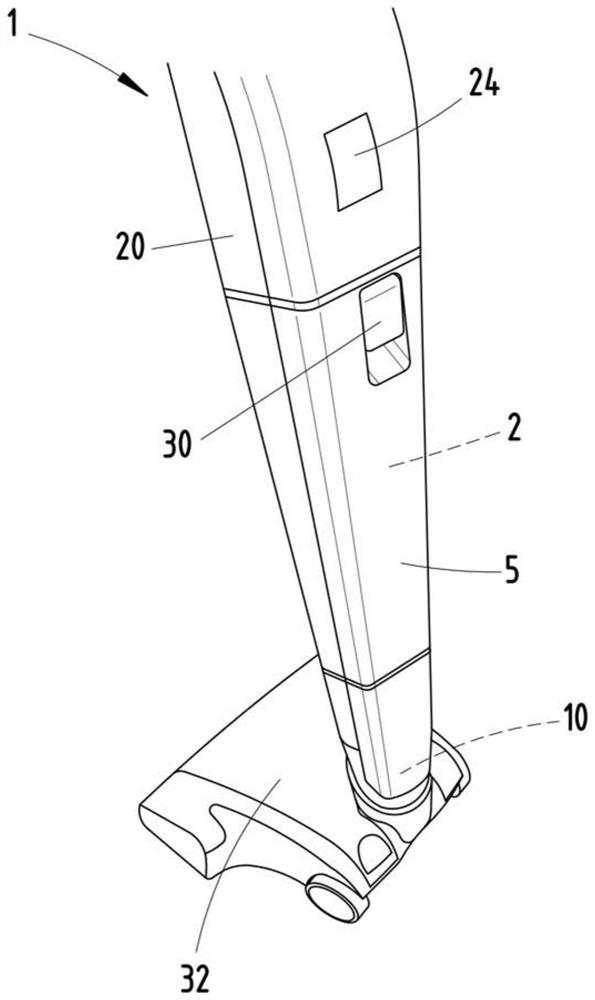

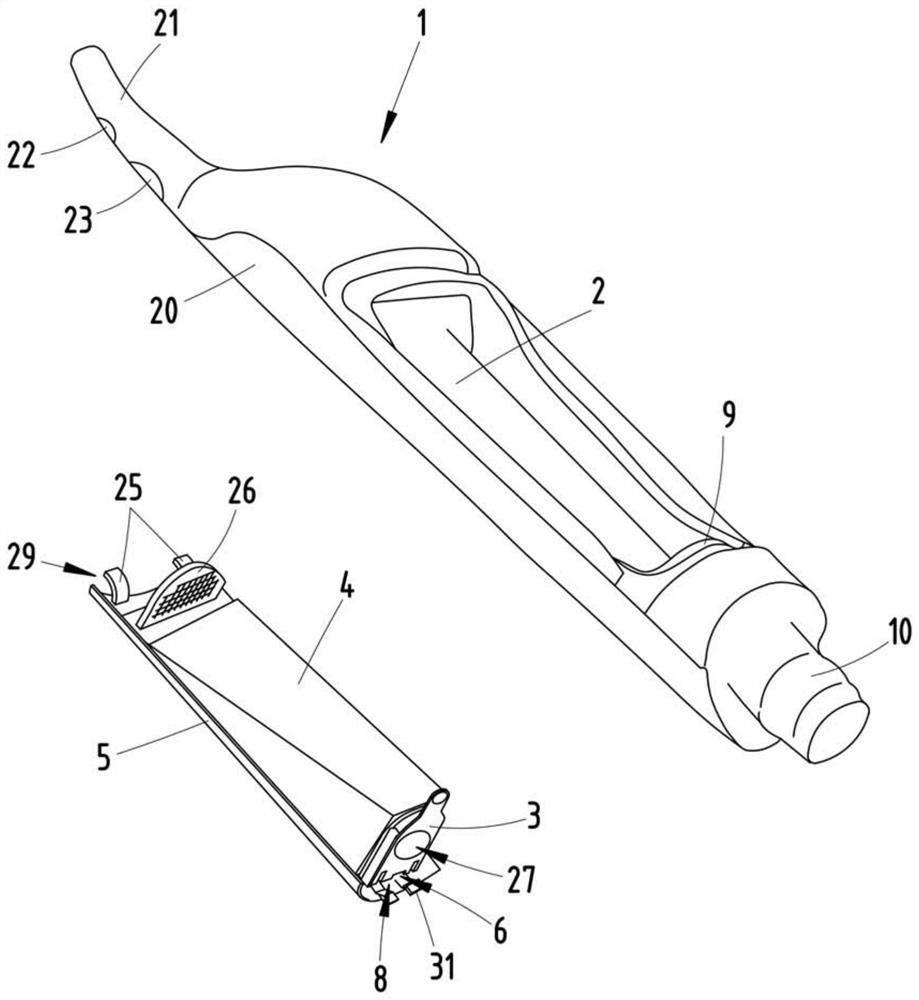

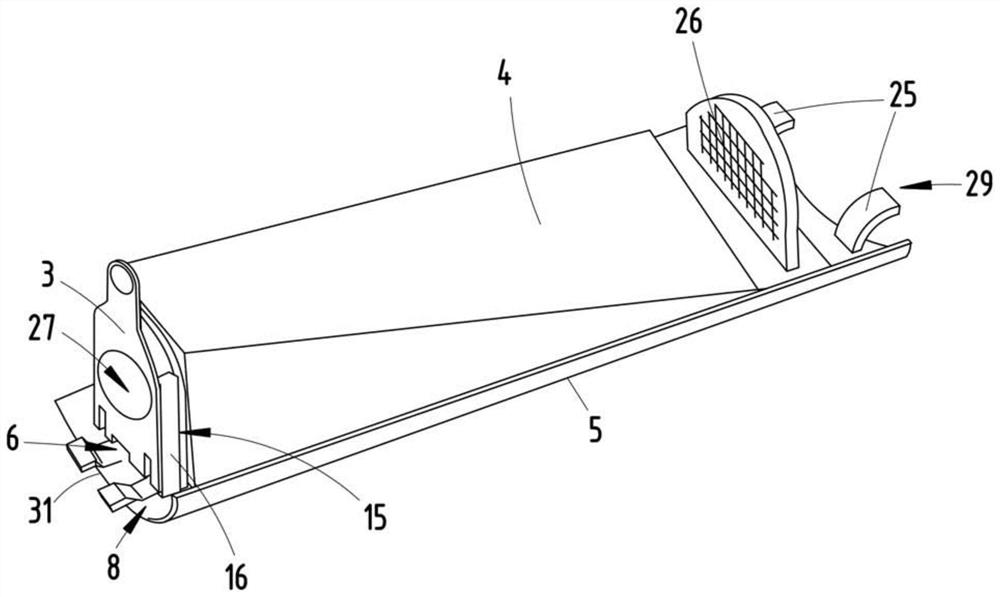

[0028] figure 1 A suction cleaning device 1 according to the invention is shown, which is designed here, for example, as a battery-operated vacuum cleaner. The suction cleaning device 1 has a housing 20 with a shaped handle 21 (see figure 2 ), for guiding the suction cleaning device 1 by the user. On the side of the suction cleaning device 1 facing away from the handle 21 , the housing 20 has a suction connection 10 to which an accessory, here eg a bottom suction nozzle 32 , is connected. The suction cleaning device 1 has a motor-fan unit, not shown in detail, which is used to suck the suction material into the suction cleaning device 1 . On the lever 21 there is a switch 22 for switching the motor-fan unit on and off, and a selector switch 23, by means of which the different power stages of the motor-fan unit can be selected. Furthermore, on the housing 20 of the suction cleaning device 1 there is a display device 24 which shows the state of charge of the battery of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com