A shell automatic insertion machine for relay

A relay and housing technology is applied in the field of automatic relay housing insertion machines, which can solve the problems of unguaranteed relay quality and low installation efficiency, and achieve the effects of simple structure, high production efficiency and reduced labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

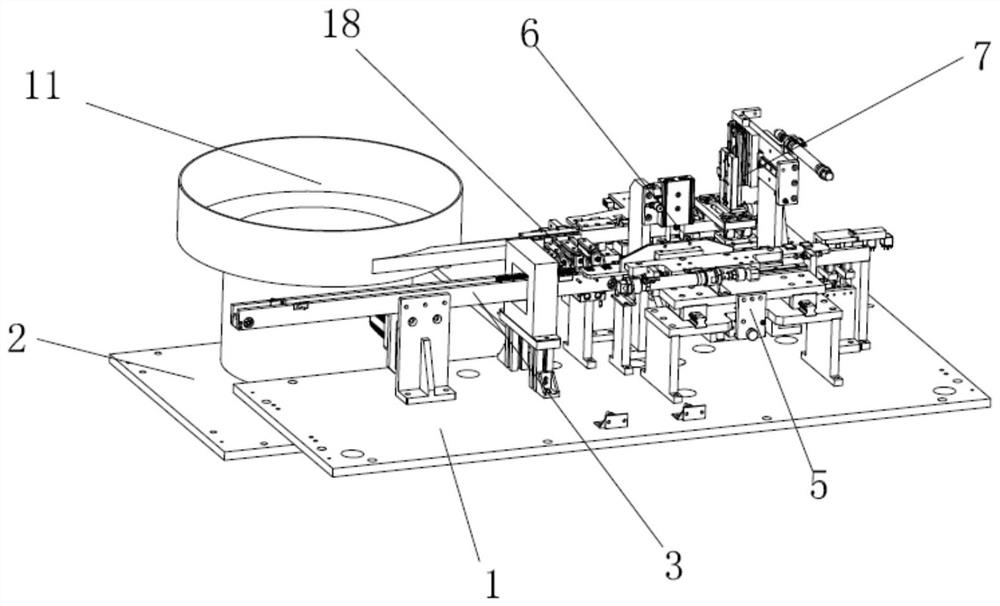

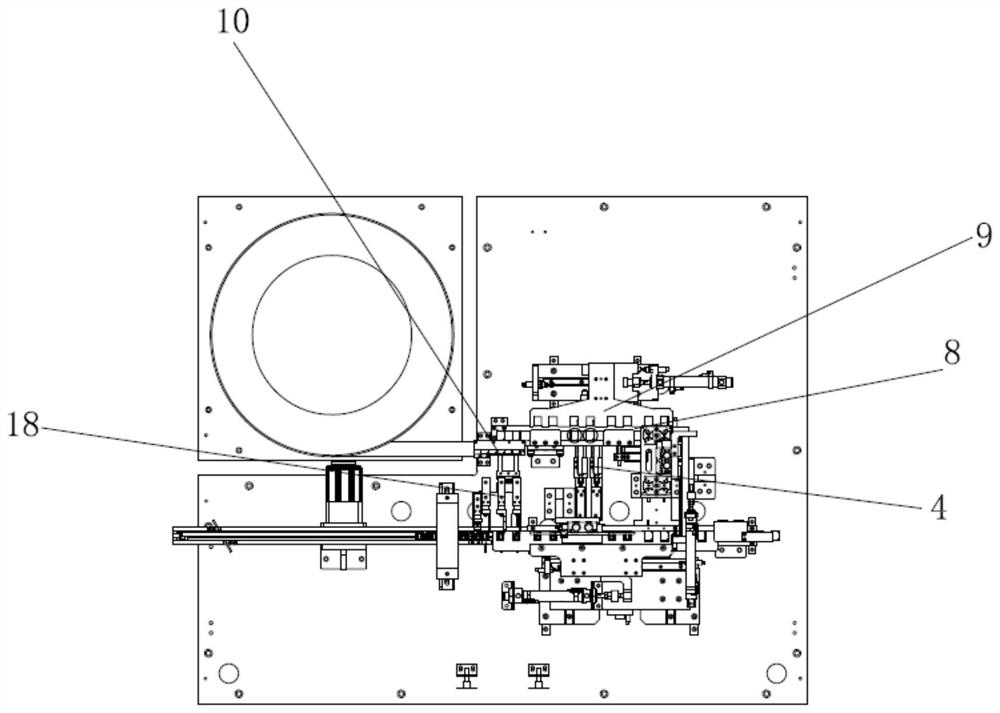

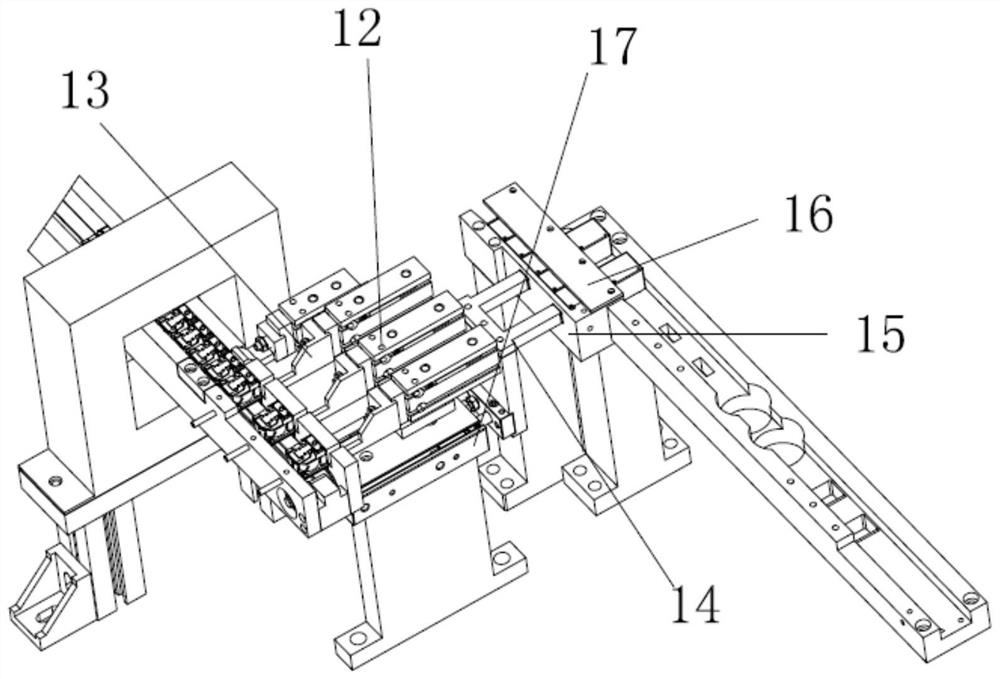

[0036] When assembling the relay housing, the housing is firstly output from the output track through the housing vibration plate 11, and sent to the housing conveying track 8 through the transfer platform 10, and the housing is conveyed by the housing conveying manipulator. 9 Slide on the housing conveying track 8 and move to the end of the housing conveying track 8. At the same time, the relay rough embryo on the relay conveying track 3 is slid and conveyed to the end of the relay conveying track 3 by the relay conveying manipulator 5, and finally the housing is started. The plug-in manipulator 7 is inserted, and the plug-in cylinder 27 on the shell-plug manipulator 7 moves toward the casing conveying rail 8 until the rear clamping part of the lower pressing block 24 of the casing is located on the casing conveying rail 8 and stops moving the plug-in cylinder. 27, then start the plug-in cylinder 27, the plug-in cylinder 27 controls the lower pressing block 24 of the casing to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com